Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

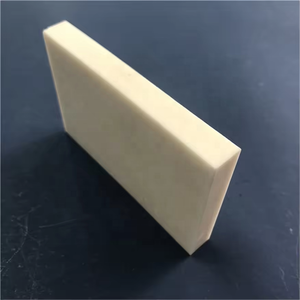

Overview of High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part)

Specification of High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

This alumina ceramic block is industrial grade. It contains 99% aluminum oxide. This high purity makes it strong. It handles extreme conditions well. This ceramic resists very high temperatures. It works fine above 1700°C. It also withstands sudden temperature changes. This material is extremely hard. Only diamond is harder. It resists wear exceptionally well. Parts last longer under friction. The ceramic fights chemical attack strongly. Acids and alkalis don’t damage it easily. This ensures reliability in harsh environments. Electrical insulation is another key feature. It blocks electricity effectively. This is vital in electrical uses.

Manufacturers form this ceramic precisely. They use dry pressing or isostatic pressing methods. Then they fire it at ultra-high temperatures. This creates a dense, strong structure. Standard sizes are available. Custom sizes are also possible. Common shapes include plates, rods, tubes, and special designs. We can machine the blocks accurately. Grinding and polishing achieve tight tolerances. We can make very smooth surfaces. We can also create complex features.

This alumina ceramic works in many tough jobs. It serves well in furnace parts. Kiln furniture uses it often. High temperature sensors rely on it. Semiconductor processing equipment needs it. Wear parts in machinery use it. Pump seals and valve components benefit. Chemical processing equipment uses it. Lab equipment often incorporates it. Electrical insulators use it frequently. It offers a cost-effective solution. It provides long service life. It reduces downtime significantly. This material performs reliably under stress. It meets demanding industrial needs consistently.

(High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part)

Applications of High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

High purity alumina ceramic blocks contain 99% Al2O3. This material is very hard. It withstands extreme wear exceptionally well. Parts made from it last much longer than metal or plastic in abrasive conditions. It resists corrosion from strong acids, bases, and solvents. This makes it perfect for harsh chemical processing environments. Pumps, valves, and liners use this ceramic. It handles tough jobs without degrading.

The ceramic offers excellent electrical insulation. It works reliably at very high voltages. Its high dielectric strength is crucial. Semiconductor manufacturing equipment uses it extensively. Wafer chucks and process tubes need its purity and stability. It prevents contamination in sensitive electronics production. Furnace components benefit too. It handles intense heat without warping or breaking.

Medical and laboratory settings use this alumina ceramic. Its biocompatibility is key. Surgical tools and implantable devices leverage its inert nature. It doesn’t react with bodily fluids. Precision instruments require its dimensional stability. Lab equipment like crucibles and tubes rely on it. It withstands high temperatures and chemical exposure during experiments.

Industrial machinery uses alumina blocks for wear parts. Seals, bearings, and cutting tools utilize its hardness. It reduces friction and extends equipment life. The material maintains its shape under heavy loads. It won’t deform easily. Its thermal stability prevents cracking during rapid temperature changes. This is vital for kiln furniture and heat exchanger parts. Metal forming tools often incorporate alumina ceramic inserts. They provide superior wear resistance. Laser components use it for its thermal and electrical properties.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

Here are 5 FAQs about High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part:

What does “99% Al2O3” mean for this ceramic block?

It means the ceramic is made almost entirely from aluminum oxide. The number shows purity. High purity (99%) gives better performance. It makes the ceramic harder. It makes it resist heat better. It makes it stronger electrically. This level is needed for tough industrial jobs.

How much heat can this alumina ceramic block handle?

This block handles very high temperatures well. It works fine up to about 1600°C (2912°F). It keeps its strength and shape at these heats. It won’t melt easily. This makes it good for furnaces, kilns, and high-heat machinery parts. Avoid sudden temperature shocks.

Why pick this ceramic block instead of metal for industrial parts?

Ceramic beats metal in several ways here. It resists wear much better. It lasts longer rubbing against things. It doesn’t corrode like metal. Chemicals won’t eat it away. It’s an electrical insulator. Metal conducts electricity. It handles much higher heat. Metal can soften or melt. Ceramic is lighter than many metals too.

Can you get different surface finishes on these blocks?

Yes, different finishes are possible. The standard is a smooth, ground finish. This is good for most uses. You can get a very fine polish. This reduces friction even more. You can get a rougher texture. This might help with gripping or bonding. The finish depends on your application needs. Ask about options.

How do you clean and maintain these alumina ceramic blocks?

Cleaning is simple. Use mild soap and water. That’s usually enough. For tougher dirt, isopropyl alcohol works. Avoid harsh acids or strong alkalis. They might damage the surface over time. Handle blocks carefully. They are very hard but can break if dropped hard or hit sharply. Check for chips or cracks before use.

(High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part)

REQUEST A QUOTE

RELATED PRODUCTS

High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory

High Temperature Resistance 99% Al2o3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes

Customized Alumina Ceramic Block High-Temperature Resistant Wear-Resistant Insulating Plate Al2O3 Ceramic Heating Ceramic Parts

10x10x30mm 99% Alumina Ceramic Block Plate Al2o3 Tile for Industrial

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes