Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

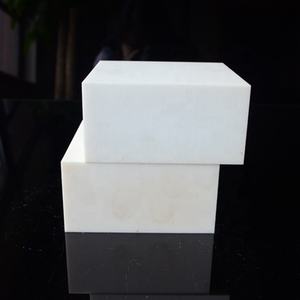

Overview of High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug)

Specification of High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

This ceramic foam block is made for tubes furnace connects. It uses top quality Alumina (Al2O3) and Steatite materials. These porcelains are exceptionally warmth resistant. They endure extreme furnace conditions without damages. The block seals furnace tube ends successfully. This prevents warm getaway. It keeps secure internal temperatures. Power effectiveness enhances because of this.

Thermal insulation is impressive. Heat stays inside the heater chamber. Outdoors air avoids. This safeguards experiments or procedures. Temperature control comes to be a lot more precise. Energy expenses drop noticeably.

The product handles thermal shock well. Rapid heating or cooling triggers no cracks. Shape continues to be steady under duplicated use. Chemical resistance is high. Many acids and antacids do not impact it. This makes certain lengthy service life. Contamination threats are low.

The foam structure is permeable yet solid. Gas flow readjusts as required. Warm clog continues to be dependable. The block is lightweight. Installation is simple. Elimination is simple for upkeep.

We produce blocks with consistent density. Constant efficiency is assured. Dimensions match conventional tubing heaters. Personalized measurements are available. Quality checks make certain every item satisfies criteria.

This plug optimizes furnace procedure. Warmth loss decreases dramatically. Tube durability rises. Process dependability improves. It fits labs, research facilities, and industrial setups. Applications consist of material testing, metallurgy, and semiconductor handling.

(High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug)

Applications of High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

Top quality alumina Al2O3 steatite ceramic foam blocks are important parts for tubing heating system connects. These plugs secure heater tube finishes successfully. The ceramic foam product uses crucial benefits. Its porous framework is crucial. This open framework enables process gases to leave securely. It stops harmful pressure from constructing inside television. Blocking stress build-up protects the furnace. It secures television itself. It safeguards the materials being refined.

Warmth resistance matters significantly here. These ceramic foam blocks handle severe heater temperatures easily. They withstand thermal shock well. Sudden temperature level modifications happen often in furnaces. The blocks stand up to these modifications without splitting. This dependability is vital for continual operation. Downtime expenses money. Fallen short plugs cause downtime.

Chemical security is another significant benefit. Alumina Al2O3 steatite ceramic resists rust. It withstands strike from hostile heater ambiences. Several heater processes entail rough chemicals. The plug material stays undamaged. It does not degrade rapidly. This makes sure a lengthy life span. Replacing plugs frequently wastes time and resources.

The foam block layout also aids with insulation. It lowers warmth loss from television ends. Maintaining warmth inside the furnace enhances performance. Better performance reduces operating costs. Energy financial savings add up in time. The plug needs to be strong mechanically. It needs to hold its form under pressure. These ceramic blocks supply that stamina. They resist physical wear during usage. Installation is simple. Operators can handle them quickly. Maintenance comes to be simpler. The blocks fit typical heater tube dimensions. Compatibility is seldom an issue. Making use of the best plug improves safety. It boosts heater efficiency. It safeguards useful heater contents.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug

What is this ceramic block?

It plugs tube furnace ends. It lets gas flow through while blocking debris. The material is alumina ceramic foam. This means aluminum oxide shaped like a sponge. It’s very strong and handles heat well.

Why use alumina foam?

Other plugs crack under extreme heat. Alumina foam stays stable. It doesn’t shrink or warp. The open pores let gas pass easily. This controls the furnace atmosphere. It also stops powder or samples from escaping the tube.

How hot can it get?

This block works fine up to 1600°C (2912°F). It handles constant high heat. Sudden temperature changes won’t break it. This matches most tube furnace needs. Higher temperatures need special ceramics.

What gases are safe?

It works with inert gases like argon and nitrogen. Hydrogen gas is also okay. Oxygen or air atmospheres cause no problems. The ceramic resists chemical reactions. Most common furnace gases won’t damage it.

How long does it last?

It lasts a very long time with normal use. Thermal shock resistance prevents cracks. It doesn’t wear down from heat cycles. Proper handling avoids physical damage. Replace it only if broken or severely chipped.

(High Quality Alumina Al2O3 Steatite Ceramic Foam Block for Tubing Furnace Plug)

REQUEST A QUOTE

RELATED PRODUCTS

Wearable Insulating Al2O3 Ceramic Plate Sheet Block Customized Size

Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

Al2O3 Alumina High Precision Wear and Corrosion Resistance Ceramic Block Brick Tile

Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

Customized High Precision Al2O3 Ceramic Block Part Non-Magnetic and High Strength 95% 99% Alumina Direct From