Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

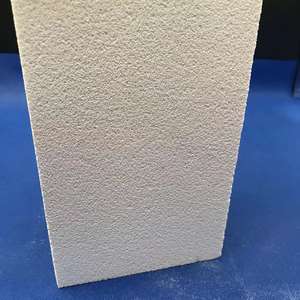

Overview of High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate)

Specification of High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

This ceramic grinding block deals with severe warmth. It’s made from pure white integrated alumina. The Al2O3 content strikes 99.5%. That means it’s very difficult and hard. It remains solid also under heavy grinding pressure. You will not see it put on down quick. This conserves cash with time.

Heat resistance is a major feature. It carries out dependably up to 1700 ° C. Thermal shock resistance is superb. Unexpected temperature changes won’t break it. This is important for many commercial processes. It ensures regular operation.

Chemical security is an additional plus. Acids and antacid barely affect it. Corrosion is hardly ever an issue. This makes it appropriate for severe chemical environments. You obtain trustworthy efficiency.

The surface is really smooth. It supplies reliable, specific grinding. Product removal rates are high. It leaves a great surface on work surfaces. This block is suitable for grinding metals. It functions well on porcelains as well. Glass grinding is an additional usual usage. Labs and manufacturing facilities rely upon it daily.

Its framework is thick and uniform. This avoids fragment dropping. Contamination of materials is decreased. You get cleaner grinding outcomes. The block maintains its shape well. Lengthy service life is ensured.

This alumina block is a workhorse. It offers wonderful value. Performance is confirmed in demanding settings. It satisfies the requirements of precision grinding.

(High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate)

Applications of High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

This ceramic block takes care of extreme warmth. It’s made from very pure alumina. The material reaches 99.5% Al2O3. This purity makes it exceptionally hard. It also makes it really challenging. It stands up to putting on down incredibly well. You can utilize it where points get truly hot. Think furnaces, kilns, or foundries. Typical products stop working there. This block stays solid. It doesn’t crack or warp easily under warmth stress and anxiety. That’s crucial for requiring work.

Its major task is grinding. It functions as a grinding plate or grating surface area. It grinds all kind of alcohol. Metals, minerals, ceramics, also glass. It provides a regular, fine finish. The surface area remains smooth over time. It doesn’t use erratically. This indicates your work surface top quality stays high. You obtain reputable results every time. You conserve cash too. It lasts a lot longer than cheaper abrasives. You replace it less typically. Downtime reduces.

Manufacturing facilities use it extensively. Metal workshops rely on it for ending up components. Ceramic producers grind powders with it. Glass makers shape and smooth edges. Mining operations crush difficult ores. Labs prepare examples specifically. Its security is vital. It won’t pollute your material. The high pureness guarantees that. You obtain clean grinding activity. No undesirable fragments mix in. It carries out regularly set after batch. You require strength and warm resistance? This alumina block provides. It deals with the most difficult grinding jobs dependably. It functions where other products simply can’t.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

What temperature can this ceramic block handle?

It withstands constant temperatures up to 1700°C (3092°F). This makes it perfect for very hot grinding jobs. Short bursts of even higher heat are usually okay. It won’t crack or weaken under normal high-heat use.

Why is 99.5% purity important?

Higher purity means better performance. The block is harder and lasts much longer. It resists wear extremely well. You get a cleaner grind finish. Contaminants stay low because the material is so pure.

Where is this alumina block typically used?

Use it for grinding tough stuff. Metals, minerals, ceramics, and glass are common. It works well in labs, factories making abrasives, and places needing precise grinding. High heat environments are no problem for it.

How do I clean and maintain it?

Cleaning is simple. Use compressed air or a soft brush after grinding. Water works for tougher residue. Avoid harsh chemicals. Check the surface regularly for damage. Proper care makes it last much longer.

Can I get custom sizes or shapes?

Yes, custom sizes and shapes are often possible. Tell us your specific needs. We can check feasibility. Custom pieces might take a bit longer to make.

(High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

High Temperature 99% 99.5% Al2o3 Alumina Ceramic Block Blank Brick

Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

Direct Customized Al2O3 Ceramic Block 95% Alumina Ceramic Parts for Industrial Grinding Welding Knife Processing

Heat Resistance 99% Alumina Ceramic Plate Block Industrial Al2o3 Sheet