Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

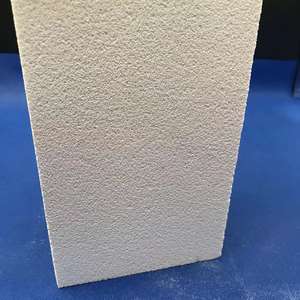

Overview of High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate

High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate)

Specification of High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate

This alumina ceramic solid block, brick, or plate uses pure Al2O3 (aluminum oxide). It handles extreme heat exceptionally well. Its main composition is over 99% alumina. This purity gives outstanding performance under harsh conditions.

The material withstands temperatures reaching 1800°C (3272°F). It stays strong and stable even at these high levels. Thermal shock resistance is another key feature. The ceramic handles rapid temperature changes well. It resists cracking or spalling.

Mechanical strength is very high. This alumina ceramic offers excellent hardness. It measures around Hv 1500 or higher. Wear resistance is superior. The material endures abrasive conditions effectively. Its density is typically 3.7 g/cm³ or above. This density contributes to its durability.

Electrical insulation properties are excellent. The alumina remains a strong insulator even at high temperatures. Chemical inertness is significant. It resists attack by many acids, alkalis, and molten metals. This makes it suitable for corrosive environments.

Surface finish possibilities are good. The ceramic can be machined precisely. Options include grinding and polishing. This ensures tight dimensional accuracy. Common sizes and shapes are available. Custom configurations are also possible.

This material is ideal for furnace linings and kiln furniture. It works well in high-temperature heating elements. Use it for thermocouple protection tubes. Semiconductor processing equipment relies on it. Foundries use it for crucibles and liners. Thermal processing fixtures benefit from its stability. Wear parts in demanding applications perform better with it. Insulators in power electronics utilize its properties. It serves reliably where other materials fail.

(High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate)

Applications of High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate

High temperature resistant alumina Al2O3 ceramic solid block brick plate withstands extreme heat. It handles temperatures above 1700°C easily. This material stays strong and stable. It doesn’t melt or warp under intense conditions. Alumina ceramic resists chemical attacks too. Acids and alkalis cause little damage. This makes it ideal for tough industrial jobs.

Factories use these blocks in furnace linings. They protect the furnace structure from heat damage. The bricks line kilns for metal treatment. They keep heat inside efficiently. This saves energy during smelting or annealing. Foundries place them in ladles and crucibles. Molten metal flows over them safely. They prevent leaks and contamination.

Chemical plants install alumina plates in reactors. They handle corrosive substances without eroding. Pipes and valves made from this ceramic last longer. They avoid rust and degradation. Power stations use these bricks in boiler systems. They endure high-pressure steam and flames. This reduces maintenance shutdowns.

Electronics manufacturers choose alumina plates for insulation. They mount circuits on them in high-heat devices. The ceramic blocks electricity reliably. Semiconductor tools use them as wafer supports. They don’t react with sensitive materials. Labs pick them for high-temperature test equipment. They provide stable surfaces for experiments.

Mining equipment benefits from alumina brick linings. Crushers and mills face less wear from abrasive ores. Aerospace parts use this ceramic for thermal shields. It guards components from engine heat. Alumina blocks are in welding nozzles and cutting tools. They resist sparks and slag. Food processing machines use them too. They meet hygiene standards and tolerate cleaning chemicals.

These ceramic blocks are heavy-duty solutions. They replace metals in extreme heat zones. They cut replacement costs and downtime. Industries trust them for critical high-heat applications.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate

What exactly is this alumina ceramic block?

This is a solid piece made from aluminum oxide powder. We compress and fire the powder at very high temperatures. The result is a dense, hard ceramic block. It withstands extreme heat without melting or deforming.

Why is it so good with high temperatures?

Alumina ceramic has a very high melting point, over 2000°C. Its chemical structure stays stable even when hot. It doesn’t easily react with other materials at high heat. This makes it reliable for intense heat applications.

Where would I use this high-temperature brick?

Use it inside furnaces and kilns as linings. It works well as setters and supports for firing other ceramics or metals. It’s good for burner nozzles, heat shields, and thermocouple protection tubes. Any place needing strong, heat-proof material benefits.

Can it handle sudden temperature changes?

Yes, but it depends on the grade. Higher purity alumina generally handles thermal shock better. Thicker sections crack more easily than thinner ones with fast temperature shifts. It’s tough, but avoid very rapid heating or cooling if possible.

What sizes and shapes can I get?

Manufacturers offer standard blocks, bricks, plates in many sizes. Common thicknesses range from a few millimeters up to 100mm or more. Length and width vary significantly. Custom shapes and sizes are often possible, though they cost more.

(High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate)

REQUEST A QUOTE

RELATED PRODUCTS

99% Al2O3 0-1mm Bauxite Ore White Fused Alumina for Ceramic Industry Raw Materials From Aluminium & SiO2 Block & Brick Patterns

Good Temperature Wear Resistance Al2o3 Alumina Ceramic Block

High Temperature 99% 99.5% Al2o3 Alumina Ceramic Block Blank Brick

High Purity Al2o3 Ceramic Block Square Alumina Ceramic Plate Brick

Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic