Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

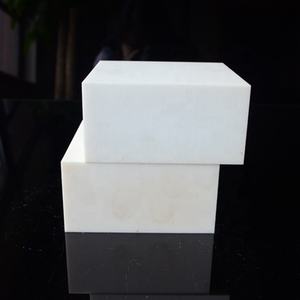

Overview of High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block

High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block)

Specification of High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block

This high temperature wear immune ceramic plate is made from 96% alumina (Al2O3). It uses remarkable efficiency in hard conditions. The high alumina content is key. It provides the plate exceptional hardness. This firmness straight combats wear. The plate stands up to abrasion incredibly well. It deals with moving friction and fragment influences. It lasts a lot longer than steel in unpleasant settings.

Warm resistance is another major stamina. This plate functions reliably at temperatures as much as 1650 ° C (3000 ° F). It maintains its strength and shape also under intense warmth. It deals with quick temperature level adjustments well. Unexpected heating or cooling down normally creates splitting. This plate minimizes that threat. It uses great thermal shock resistance.

The material is really dense. Its structure is fine-grained. This density blocks chemical attack. Home plate withstands numerous acids and antacids. It won’t rust or corrode like metals. It provides exceptional electrical insulation. This serves in electric applications. The surface is smooth. This level of smoothness lowers rubbing better. It assists products slide conveniently over it.

These plates are strong blocks or blocks. They are very tight. They have high compressive strength. They lug hefty lots without flexing. They are perfect for demanding industrial work. You find them in heating system linings, kiln furnishings, use linings, and chutes. They secure devices from severe warmth and wear. They expand machinery life significantly. They lower costly downtime for repairs. They are a trustworthy solution for severe environments.

(High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block)

Applications of High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block

High temperature wear immune Al2O3 96% alumina ceramic solid plate block blocks offer exceptional performance in challenging conditions. Their high alumina web content gives superior solidity. This firmness makes them incredibly immune to abrasion. They handle continuous rubbing and scraping extremely well. These porcelains also stand up to extreme heat. They maintain stamina and shape at temperatures over 1600 ° C. This mix is beneficial for hefty sector.

These plates and blocks are perfect for lining equipment. They secure versus rapid wear. Heaters benefit significantly. They line heating system walls and fireplaces. They protect the framework from intense heat and molten material dash. Kilns use them thoroughly. Kiln furnishings like setters and saggers prevail applications. They support items throughout firing. Their thermal security avoids warping. Their smooth surface area avoids product sticking.

Material handling systems see substantial wear. Alumina ceramic plates line transfer chutes and hoppers. They reduce damages from unpleasant ores, coal, and minerals. They extend tools life considerably. Conveyor system parts make use of these porcelains. Put on plates and liners lower downtime. Nuclear power plant use them in ash handling systems. Fly ash is highly erosive. Alumina linings resist this efficiently.

Chemical processing plants use these porcelains. They withstand corrosion from rough acids and alkalis. They line reactors, containers, and pipes. Their inert nature avoids contamination. Mining operations rely on them. They line cyclones, hydrocyclones, and classifier containers. They endure consistent bit impact and slurry flow. They are essential in concrete manufacturing. Crushers, separators, and grinding mills utilize them. They secure against clinker abrasion. Steel mills install them in crucial areas. They line tuyeres, heater blocks, and thermocouple defense tubes. They make it through the harsh steelmaking atmosphere.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block

People ask many things about our High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block. Here are the top five questions.

What is this alumina ceramic block? It is a solid plate made mostly from alumina (Al2O3). The amount is 96%. This makes it incredibly hard. It handles extreme heat well. It resists wearing down from friction. It is used where things get hot and abrasive, like furnace linings or chutes.

How hot can it get? This ceramic handles very high temperatures. Its maximum continuous use temperature is about 1600°C (2912°F). It keeps its strength and shape at these heats. Many metals fail much earlier. This makes it good for very hot places.

Is it really wear resistant? Yes, extremely. Alumina ceramic is much harder than steel. It is near diamond hardness. Abrasive materials sliding or hitting it cause little damage. This hardness is its main defense against wear. It lasts much longer than metal in abrasive conditions.

Does it resist chemicals? It does. Alumina ceramic is inert. Most acids and alkalis do not affect it. Strong chemicals, like hot acids or molten metals, usually don’t harm it. This chemical resistance adds to its durability in tough places.

How do you install these blocks? You mount them onto a backing structure. Usually, you bolt them on. Metal brackets or specially designed anchors hold them securely. You can also embed them in castables. The method depends on the specific job. Proper installation is key for best performance.

(High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Alumina Ceramic Block High-Temperature Resistant Wear-Resistant Insulating Plate Al2O3 Ceramic Heating Ceramic Parts

More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

Custom Ra0.2 Alumina Ceramic Part Block High Purity 99 Al2o3 Ceramic Plate Substrate Sheet -With Laser Engrave ” X ” One Side

Factory Supply Low 99%Al2O3 Parts Alumina Block Insulating Ceramic Socket

Customized Size High Temperature Resistant 99% 96% 95% Al2o3 Alumina Ceramic Furnace Part Component Tiles Block Plate