Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

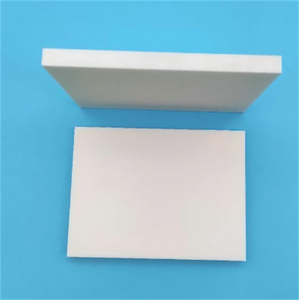

Overview of High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory

High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory)

Specification of High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory

Our high wear-resisting ceramic overview blocks are developed hard. They use 99% Al2O3 high purity alumina. This material is exceptionally hard. It uses exceptional resistance to abrasion and wear. These blocks last much longer than metal parts. They minimize downtime and substitute prices substantially.

The structure is dense and fine-grained. This supplies superb mechanical strength. It deals with heavy tons without damaging. The surface area is extremely smooth. This creates low rubbing. Relocating parts slide quickly. You get smooth procedure and regular efficiency.

These overview blocks withstand chemical strike well. They manage acids and alkalis without wearing away. They do reliably in severe environments. Temperature level extremes are no problem. They work from extremely cold to really warm problems. Thermal shock resistance is high. Sudden temperature level adjustments trigger no fracturing.

We make these blocks for requiring applications. They are best for industrial equipment. Use them in overviews, slides, tracks, and wear plates. They operate in fabric equipments, packaging lines, automation devices, and material handling systems. They enhance accuracy and resilience.

Our manufacturing facility focuses on OEM production. We provide customized services. We form blocks to your precise drawings. We satisfy your specific size demands. We provide various surface finishes. We make certain tight dimensional tolerances. Your application gets the excellent fit.

We ensure constant top quality. Every batch fulfills strict standards. You obtain dependable components for your machinery.

(High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory)

Applications of High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory

Our manufacturing facility makes high pureness alumina ceramic overview blocks. These components have 99% Al2O3. This product is extremely tough. It withstands wear very well. These guide blocks last much longer than steel components. They deal with challenging conditions without damages.

Alumina ceramic blocks slide smoothly. They decrease friction substantially. This lowers power use. Equipments operate much more successfully. Maintenance prices lower. Production downtime is reduced.

These guide obstructs work in many demanding locations. Use them in hefty equipment like presses. Use them in cutting devices. Use them in product handling systems. They direct moving parts precisely. They withstand consistent rubbing. They resist influences. They tolerate high temperatures. They deal with harsh chemicals. This makes them very trustworthy.

Our factory concentrates on OEM production. We make personalized alumina ceramic overview blocks. We create components to your exact specifications. We consider dimension, shape, and resistance needs. We offer various surface finishes. We give numerous installing options. We make certain components fit flawlessly into your tools.

We manage the whole production process. We utilize sophisticated sintering strategies. We assure consistent premium quality. Every set meets stringent criteria. We check material homes extensively. We inspect dimensions exactly. Our parts deliver dependable performance. They prolong the life of your machinery. They boost general system operation.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory

What is high purity alumina ceramic? High purity alumina ceramic is a material made from 99% aluminum oxide. It is extremely hard. This material works well in tough industrial settings. It resists wear effectively. It handles high temperatures. It stays stable against chemicals.

Why choose alumina ceramic for guide blocks? Alumina ceramic reduces friction better than metal. It lasts much longer. It needs less maintenance. It works in harsh environments. It prevents rust and corrosion. It keeps its shape under heavy loads.

How wear-resistant are these guide blocks? These guide blocks are highly wear-resistant. Their hardness is very high. The 99% alumina composition fights abrasion. They perform in high-friction applications. They outlast steel parts by many times.

Can you customize the guide blocks? Yes, we customize guide blocks fully. We are an OEM factory. We follow your exact drawings. We adjust sizes, shapes, and hole patterns. We meet your specific requirements. We ensure parts fit your machinery perfectly.

How do I order these parts? Ordering is simple. Tell us your needs. Send your specifications or drawings. We give a fast quote. We make samples for approval. After you confirm, we produce the order. We ship on schedule.

(High Wear-resisting 99% al2o3 high purity alumina ceramic guide block structure part OEM factory)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistance 99% Al2o3 Ceramic Block Plate Alumina Board/Brick/Tile With Holes

Heat Resistance 99% Alumina Ceramic Plate Block Industrial Al2o3 Sheet

Custom high temperature alumina al2o3 ceramic plate block crucible pot cauldron ashtray

High Temperature 99% 99.5% Al2o3 Alumina Ceramic Block Blank Brick

High Purity 99% Alumina Ceramic Block Al2o3 Ceramic Brick Chunk