Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

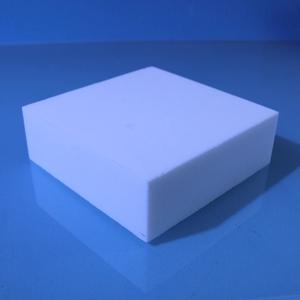

Overview of Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate)

Specification of Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

Here’s the spec web content for the Higher Pureness 95% Alumina Porcelain Bar, Block, Plate, and Substratum:

This material is 95% Alumina Ceramic (Al2O3). It offers solid efficiency. The high pureness level is key. This purity offers the ceramic great buildings. It has high mechanical stamina. This makes it really hard. It resists wear exceptionally well. The ceramic takes care of high warmth well. It keeps its shape at temperature levels as much as 1500 ° C. It also fights off chemicals properly. Acids and bases do not damage it conveniently. Its electric insulation is exceptional. This makes it safe for electric uses. The surface area is extremely smooth. This is necessary for precision parts. The ceramic is thick. This density contributes to its sturdiness.

We provide this 95% Alumina Ceramic in various shapes. You can obtain solid bars. You can obtain thick blocks. You can obtain thin plates. You can get level substratums. The dimensions are adjustable. We can cut it to your required dimensions. The coating is generally fine. Often a refined coating is offered.

This material works in difficult conditions. It benefits heating system parts. It benefits kiln furniture. It holds components throughout shooting. It is made use of in wear-resistant components. Pump seals use it. Valve seats use it. It works as electric insulators. These insulators enter spark plugs. They go in power systems. The thin plates act as substratums. Electronics utilize these substrates. Sensors utilize them. Heating elements utilize them. The ceramic is secure. It doesn’t transform a lot gradually. This stability is trusted. It is crucial for technological applications. Its performance is consistent.

(Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate)

Applications of Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

This alumina ceramic product consists of 95% Al2O3. It uses terrific solidity and puts on well. It takes on high temperatures easily. This makes it valuable for several laborious. It stands up to chemicals strongly. It protects electrical energy extremely efficiently. These functions are key for requiring applications.

People make use of alumina ceramic bars for structural components. They operate in furnace linings and kiln furniture. They take care of extreme warmth well. They are steady under mechanical tons. They are also machined right into precise shapes. These forms come to be parts for pumps and shutoffs. They withstand unpleasant slurries and harsh liquids. This prolongs devices life dramatically.

Thin alumina ceramic plates are level and smooth. They are optimal for wear surfaces. They line chutes and hoppers in mining. They shield against unpleasant materials. They are also used as electrical insulators. They separate elements in high-voltage equipment. They prevent electric shorts. They are secure under thermal biking. This integrity is vital.

Alumina ceramic blocks are thick and durable. They support heavy loads quickly. They form the base for high-temperature processes. They are machined right into personalized components. These components hold parts during warmth therapy. They are inert and tidy. They are vital in semiconductor manufacturing. They do not pollute sensitive procedures.

The alumina ceramic substrate is a slim, flat sheet. It has a very fine surface area coating. It is the base for electronic circuits. Thick movie circuits are published onto it. It gives outstanding electrical seclusion. It dissipates warmth successfully. This keeps electronic components cool down. It is made use of in power modules and LED plans. Its thermal conductivity is great. Its dimensional stability is high. This guarantees circuit accuracy.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

What is this alumina ceramic?

It’s a special ceramic block. It contains at least 95% aluminum oxide (Al2O3). This high purity makes it very strong. It resists wear well. It handles high heat easily. People use it in tough jobs.

Why is 95% purity important?

Higher purity means better performance. The material gets harder. It withstands much higher temperatures. It becomes a stronger electrical insulator. It resists chemical attacks better. Lower purity ceramics don’t last as long.

Where is this ceramic used?

It goes into many industrial parts. Think about wear plates in machinery. It lines pipes carrying abrasive materials. It serves as insulating bases in electronics. It works in high-temperature furnace parts. It protects sensitive equipment.

What are the main advantages?

Its hardness protects against scratches. Its heat resistance allows use in ovens. It doesn’t conduct electricity safely. It resists corrosion from chemicals. It stays stable over time. This saves money on replacements.

Is it fragile?

Yes, it can break if hit hard. It is a ceramic, so it’s brittle. Handle it carefully during installation. Avoid sharp impacts. Design parts to avoid stress points. It lasts a long time when installed correctly.

(Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate)

REQUEST A QUOTE

RELATED PRODUCTS

Manufacturing Dry Pressing Moulding 99% Al2O3 Alumina Ceramic Block Plate

95% Alumina Block Heat Resistance Al2O3 Ceramic Grinding Plate

XTL Sintyron White Round Block Wear Resistant High Hardness Al2o3 Alumina Ceramic Plate

99% Al2O3 Corundum Block Brick for Ceramic Oven

Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block