Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

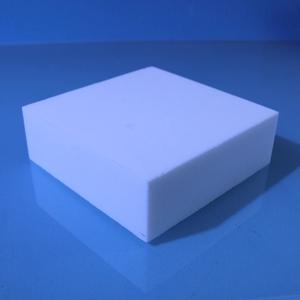

Overview of Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block

Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block)

Specification of Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block

This alumina ceramic plate supplies high efficiency in demanding commercial setups. The material is 95% pure light weight aluminum oxide. This make-up supplies superb properties. It withstands extreme heat effectively. You can use it continuously approximately 1600 ° C. It deals with unexpected temperature level modifications without fracturing. This makes it dependable for heaters and kilns. Electrical insulation is another crucial benefit. It quits existing circulation effectively even at high voltages. This is crucial for electric components and power systems. The plate is really tough and strong. It resists wear and abrasion fantastically. It stays solid under heavy lots. Chemical resistance goes over also. It doesn’t react with many acids and alkalis. Rough processing atmospheres will not harm it conveniently. Surface surface is smooth. This minimizes rubbing. Accuracy machining is possible. You obtain tight dimensional tolerances. Common dimensions are available as sheets or blocks. Thickness differs based upon your needs. Normal usages consist of heater linings, heating system sustains, and electric insulators. It works well for sensing unit security and welding components. It works as a secure spacer in high-temperature settings up. This ceramic gives reliable thermal and electric splitting up. Its durability lowers substitute prices. It keeps procedures running smoothly under tough problems. These plates manage extreme warm and electric anxiety daily.

(Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block)

Applications of Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block

Factories require hard insulators. Industrial 95% Alumina Ceramic plates deliver. This material is nearly pure aluminum oxide (Al2O3). It uses impressive efficiency in extreme settings. Extreme warm is a major difficulty. Alumina ceramic manages it well. Temperature levels over 1600 ° C do not harm it. This makes it perfect for heater cellular linings. It’s excellent for kiln furniture. Warmth treatment components profit greatly.

Electrical security is crucial. This ceramic is a leading insulator. It does not carry out electrical energy. High voltages present not a problem. Power electronic devices utilize it commonly. It secures sensitive components. Semiconductor manufacturing relies upon it. Spark plugs require reputable insulation. Alumina gives this consistently.

Chemical attacks wreck many products. Alumina ceramic withstands them. Acid bathrooms can’t penetrate it. Caustic solutions leave it unhurt. Molten metals do not stick to it. This longevity is vital. Chemical processing equipment makes use of alumina plates. Foundries need protection from liquified metal splash. Labs utilize it for harsh experiments.

Mechanical strength issues under lots. Alumina uses good firmness. It withstands hefty weights. It stands up to wear over time. This extends part life dramatically. Factory utilize it as sturdy spacers. Accuracy grinding components require level, steady bases. Alumina plates offer this dependably. Welding jigs remain dimensionally stable.

Handling is simple. These plates are stiff. They preserve exact forms. Their level surfaces make sure good contact. Designers specify them for critical spaces. They offer consistent electric seclusion. Thermal obstacles operate predictably. Semiconductor wafer handling needs pureness. Alumina fulfills strict contamination standards. Laser systems use it for secure platforms. High-power resistor assemblies need its insulation. Brazing fixtures use it for warmth containment.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block

What is the 95% alumina ceramic insulation plate made of? It uses 95% aluminum oxide. The rest includes binding agents. This mix ensures strong performance.

Why pick this alumina ceramic plate for industrial use? It handles extreme heat well. It blocks electricity effectively. It resists wear and chemicals too. These traits suit tough factory conditions.

Where can I apply this alumina ceramic plate? Use it in furnaces or kilns. It works for electronics needing insulation. It serves as spacers in high-voltage setups. It fits anywhere demanding heat barriers.

How durable is this alumina ceramic plate? It lasts long under stress. It withstands temperatures over 1500°C. It doesn’t crack easily. It stays stable in harsh settings.

Can I get custom sizes for this plate? Yes, manufacturers cut it to order. Specify thickness or shape needs. They adjust for holes or edges. Custom pieces fit unique projects.

This plate ships ready for industrial jobs. It meets safety standards. It reduces energy waste. Buyers save on maintenance costs.

(Industrial 95% Alumina Ceramic Insulation Plate Sheet Al2o3 Spacer Block)

REQUEST A QUOTE

RELATED PRODUCTS

Wearable Insulating Al2O3 Ceramic Plate Sheet Block Customized Size

High-Purity Custom-Made Alumina Ceramic Blocks

More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

Polished Al2O3 Ceramic Plate Alumina Square Block

High Purity Al2o3 99% Alumina Ceramic Block Brick 25*50*10mm