Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

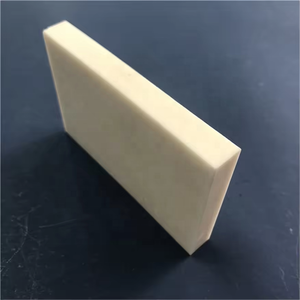

Overview of Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile)

Specification of Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

This alumina ceramic block provides reliable high-temperature insulation. Its composition is 99% aluminum oxide (Al2O3). This high purity is key. It ensures top performance under extreme conditions. The material withstands very high temperatures. Its maximum service temperature reaches 1700°C (3092°F). It handles thermal shock well too. Sudden temperature changes won’t easily crack it. This durability is crucial for demanding industrial processes.

Electrical insulation is a major strength. The alumina ceramic offers excellent dielectric properties. It effectively blocks electric current. This makes it safe for electrical applications. It prevents short circuits and protects equipment. Mechanical strength is also high. The block resists wear and abrasion effectively. It maintains its shape under load. This toughness ensures a long service life. It won’t degrade quickly in harsh environments.

Common shapes include blocks, bricks, and tiles. Standard sizes are widely available. Custom dimensions are often possible. The surface finish is typically smooth. This allows for easy installation. It ensures good contact where needed. The material is chemically inert. It resists attack from many acids and alkalis. This chemical stability adds to its reliability. It performs consistently in corrosive atmospheres.

These insulator blocks are essential in many industries. They line high-temperature furnaces effectively. They protect kiln furniture and heating elements. Electrical applications use them as stable supports. Foundries rely on them for metal handling. Semiconductor manufacturing uses them in critical processes. They are found in heat treatment fixtures. They serve as stable bases for sensors. Their role is vital wherever heat and electricity meet.

(Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile)

Applications of Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

This alumina ceramic insulator uses 99% pure aluminum oxide (Al2O3). It stops electricity extremely well. It handles very high temperatures easily. This makes it perfect for tough industrial jobs.

Factories use these blocks, bricks, and tiles in many places needing electrical insulation and heat resistance. They line high-temperature furnaces. The material doesn’t melt or crack under intense heat. It protects the furnace structure. Kilns and ovens use them too. They hold parts during firing without breaking down.

Electrical equipment relies on these insulators. They isolate live parts safely. You find them in power distribution systems. They prevent short circuits. They are inside heavy machinery. They protect sensitive electronics from heat and sparks.

The material resists wear exceptionally well. It lasts a long time in abrasive conditions. It lines equipment handling gritty materials. It minimizes damage from constant friction. It shields parts in sandblasting machines. It reduces maintenance costs.

Chemical plants value its stability. It doesn’t corrode easily. It withstands harsh acids and solvents. This ensures reliable performance in chemical processes. It keeps electrical systems safe in corrosive areas.

Welding fixtures use these insulators. They hold parts securely. They prevent stray currents from damaging the weld. Foundries use them near molten metal. They provide a safe, non-conductive barrier. They handle the extreme heat near furnaces.

Spark plugs and ignition systems use small alumina parts. They isolate the high voltage spark. Automotive sensors depend on this material. It provides stable electrical insulation in hot engine environments.

Its strength is important. It handles heavy loads without bending. It supports other furnace components. It maintains its shape under pressure. This dimensional stability is crucial for precise industrial setups. It ensures consistent spacing and alignment.

These properties make Al2O3 ceramic indispensable. It solves problems in high-heat, high-wear, electrically sensitive applications. It offers a reliable, long-lasting solution.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile

What is this Alumina Ceramic Insulator Block?

This is a solid ceramic piece. It’s made almost entirely from Aluminum Oxide (Al2O3). We call it Alumina. The purity is very high, about 99%. This high purity gives it excellent properties. It works well for electrical insulation. It handles high heat too. People use it in tough industrial jobs. It comes as blocks, bricks, or tiles. The shape depends on the job.

What makes this Alumina Block special?

Its key features come from the 99% Alumina. It resists extreme heat very well. It can handle temperatures over 1700°C. It’s also a superb electrical insulator. Electricity doesn’t pass through it easily. It’s very hard. This hardness makes it resist wear. It lasts long in abrasive conditions. It’s also chemically stable. Most chemicals don’t damage it. It won’t rust like metal.

How hot can it get before failing?

This alumina block handles very high heat. Its maximum continuous use temperature is around 1650°C to 1750°C. It depends on the exact conditions. Short bursts of even higher heat are possible. This makes it suitable for furnaces, kilns, and high-temperature processes. It won’t melt or deform easily.

Is it good for electrical insulation?

Yes, excellent. That’s a primary use. The 99% Alumina has very high electrical resistance. It stops electricity flow effectively. This remains true even at very high temperatures. It outperforms many other materials when things get hot. It’s reliable for insulating electrical components in harsh environments. Think heating elements or thermocouples.

Where do people use this Alumina Block?

Its toughness finds many places. Common uses are furnace linings and kiln furniture. It holds parts during firing. It’s vital in high-temperature electrical insulation. You find it protecting heating elements. It insulates thermocouples. It acts as a barrier in welding fixtures. Its wear resistance makes it good for guides and liners where abrasion happens. It works in chemical plants too.

(Industry Abrasive 99% Al2o3 Alumina Ceramic Insulator Block Brick Tile)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Ceramic Block Industrial Grade 99 Al2O3 Ceramic Part

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes

Customized Al2O3 Ceramic Mechanical Parts Wear Resisting Ivory White Alumina Ceramic Blocks

Customized High Precision Al2O3 Ceramic Block Part Non-Magnetic and High Strength 95% 99% Alumina Direct From

Square 99% Alumina Ceramic Sheet Al2o3 Plate Block With Hole