Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

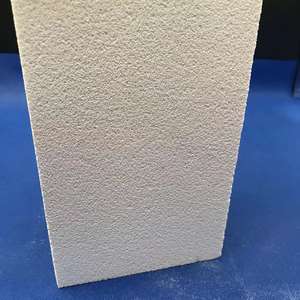

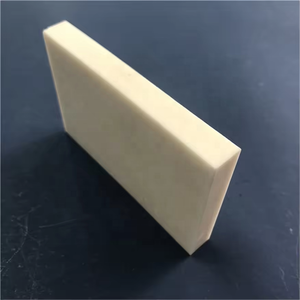

Overview of More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces)

Specification of More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

Specification of More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

These bricks are made for ceramic heater linings. They have over 92% alumina (Al2O3). This high alumina level gives them excellent homes. They endure very heats quickly. Ceramic shooting needs extreme warmth. These blocks manage it accurately.

Their heat resistance is exceptional. They withstand melting and softening. Heating system temperatures remain steady. This is critical for regular ceramic high quality. Abrupt temperature level modifications happen throughout firing. These blocks handle thermal shock well. They resist breaking from rapid heating or air conditioning. This prolongs the furnace cellular lining’s life dramatically.

Mechanical stamina is high. The bricks stand up to abrasion and effect damages. Packing and dumping ceramics occurs typically. The lining faces consistent wear. These bricks stand up versus this punishment. Their dense framework aids. It avoids slag and gases from penetrating. Chemical strike inside the kiln is lowered. Furnace contamination is minimized.

Setup is simple. The blocks fit precisely. They maintain dimensional stability at high warmth. This develops a limited, reliable lining. Warm loss is lowered. Energy savings are feasible. Maintenance expenses drop gradually. The lining lasts longer before needing substitute.

These bricks offer trustworthy performance. They secure the furnace structure. Ceramic production runs become extra foreseeable. Downtime for fixings is less frequent. Utilizing high-purity alumina bricks makes sense. It makes sure heater long life and process security.

(More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces)

Applications of More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

High alumina lining bricks with over 92% Al2O3 are crucial inside ceramic heaters. These blocks handle severe conditions. They are essential for effective ceramic manufacturing. The high alumina material makes them unbelievably immune to warmth. This permits them to withstand kiln temperature levels easily. Normal products would certainly stop working quickly at these warms.

These blocks are extremely thick and strong. This density gives them superb toughness. They resist physical wear better than lower-grade bricks. Hefty loads and continuous activity inside the kiln don’t damage them promptly. Their long life span saves money on replacements. Manufacturing downtime is minimized substantially.

Chemical security is another significant benefit. The bricks do not react with ceramic glazes, kiln laundry, or furnace gases. This avoids contamination of the ceramic products. Product top quality remains high. The heater lining stays intact longer. Chemical attack does not deteriorate the bricks prematurely.

Thermal shock resistance is critical. Heater temperatures transform quickly during firing cycles. These bricks manage sudden home heating and cooling well. They don’t break or spall quickly. This reliability is essential for continuous procedure. Less cracking ways much better insulation and furnace integrity.

Power efficiency is additionally enhanced. The high thickness and reduced porosity of these bricks act as exceptional insulation. Warmth stays inside the kiln chamber much better. Much less warmth gets away via the walls. Fuel costs decrease. The heating system runs more effectively on the whole.

Ceramic manufacturing facilities utilize these bricks in essential kiln zones. The best sections like shooting zones benefit the majority of. They are ideal for saggers, kiln autos, and heater blocks. Assistance structures inside passage kilns rely on them. Their efficiency directly affects production result and product consistency. Selecting the ideal lining material issues substantially.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces

Product Content: High Alumina Lining Bricks (Over 92% Al2O3) for Ceramic Furnaces – 5 FAQs

1. What are the main benefits of these bricks?

These bricks contain over 92% alumina. This makes them very strong. They resist wear and high heat. They last longer in ceramic furnaces. They reduce furnace downtime. They lower replacement costs.

2. How do they handle extreme heat?

Alumina melts at very high temperatures. These bricks stay stable above 1700°C. They do not crack easily. They keep their shape under stress. They protect furnace walls from heat damage.

3. Are they resistant to chemical damage?

Yes. Ceramic materials release corrosive chemicals during firing. These bricks ignore alkalis and acids. They do not react with glazes or kiln fumes. They stay intact. They avoid contaminating your products.

4. What is their typical lifespan?

They last several years in normal use. Regular firebricks wear out faster. These bricks save money. They need fewer replacements. They handle daily furnace cycles well.

5. What sizes and shapes can I get?

Standard sizes are available. Custom shapes are possible. We make straight bricks, arch bricks, and special pieces. We match your furnace design. We ensure tight fitting. This prevents heat loss.

(More Than 92% Al2O3 High Alumina Lining Bricks For Ceramic Furnaces)

REQUEST A QUOTE

RELATED PRODUCTS

XTL Sintyron White Round Block Wear Resistant High Hardness Al2o3 Alumina Ceramic Plate

Industrial Ceramic Al2O3 High Temperature Wear Resistant Block High Hardness Alumina Precision Ceramic

Higher Purity 95% Alumina Ceramic Bar Al2o3 Alumina Ceramic Block Thin Plate Alumina Ceramic Substrate

industrial 95% alumina ceramic insulator block al2o3 component with hole

Customized Al2O3 Ceramic Part 95% Alumina Ceramic Block With Holes