Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

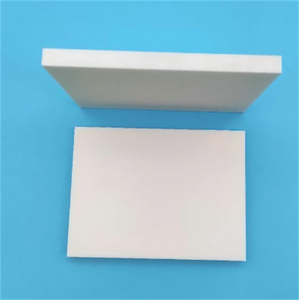

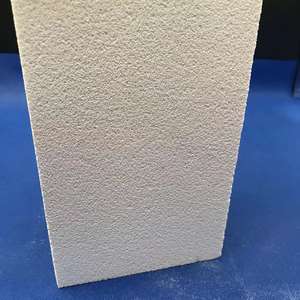

Overview of Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block is high-performance refractory materials made from premium alumina (Al₂O₃), offering exceptional thermal resistance, mechanical strength, and chemical stability. They are widely used in high-temperature industrial applications such as kilns, furnaces, and reactors, ensuring durability and efficiency in extreme conditions.

Key Features of Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

High Thermal Stability – Withstands extreme temperatures up to 1800°C (3272°F).

Superior Corrosion Resistance – Resists acids, alkalis, and molten metals.

Excellent Mechanical Strength – High hardness and wear resistance for long-lasting performance.

Low Thermal Conductivity – Enhances energy efficiency in high-heat applications.

Customizable Sizes & Shapes – Available in various dimensions to meet specific industrial needs.

High Purity (90%-99% Al₂O₃) – Ensures reliability in demanding environments.

(Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block)

Specification of Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

This alumina ceramic material reaches 99.7% purity. It’s made almost entirely from aluminum oxide (Al2O3). This high purity creates excellent performance. The material is very hard. Its Vickers hardness is extremely high. It rates harder than many steels. This hardness means great wear resistance. Parts last longer in abrasive conditions. The surface stays smooth.

The material resists high temperatures well. It keeps its strength even above 1500°C. Thermal shock resistance is good. It handles rapid temperature changes without cracking. This is important for heating cycles. Chemical stability is another key feature. It withstands strong acids and bases. Corrosion is minimal. This suits harsh chemical environments.

Electrical insulation properties are strong. It works well for electronic components. The dielectric strength is high. It prevents electrical currents from leaking. Mechanical strength is impressive. It has high compressive strength. It bears heavy loads without breaking. Flexural strength is also good. It resists bending forces.

Special shapes are possible. Complex tile and block designs are manufactured. These fit specific machinery needs. Custom geometries solve unique problems. Precision machining ensures accurate dimensions. Tight tolerances are achievable. This ensures proper fit and function.

Typical uses include wear parts. Liners for equipment see heavy abrasion. Grinding media benefit from the hardness. Insulators in electronics use this material. Furnace components handle the heat. Thermocouple protection tubes rely on it. Seal rings need the chemical resistance. Pump components face corrosive fluids. Ballistic armor uses high-grade alumina tiles.

(Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block)

Applications of Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

These Special Shape 99.7% Al2O3 Alumina Ceramic Tiles are tough. They handle extreme wear very well. Their hardness is near diamond. This makes them perfect for harsh places. They resist abrasion superbly. This extends equipment life significantly. They also handle extreme heat. Thermal shock doesn’t crack them easily. Chemical attack barely affects them. This includes strong acids and alkalis. These properties are crucial for demanding industries.

Mining operations use them extensively. They line chutes, hoppers, and pipes. Ore and gravel flow constantly. This causes severe wear. The tiles protect the steel underneath. Mineral processing plants rely on them too. Cyclones and classifiers face abrasive slurries. The tiles shield these critical parts.

Steel mills need them for protection. Blast furnace equipment gets extremely hot. Abrasive materials move fast there. The tiles line areas like bell-less tops. They also protect burner blocks and thermocouple sleeves. Power plants utilize them in coal handling. Pulverizers and ash systems are abrasive. The tiles reduce downtime and maintenance costs.

Cement production is another key area. Raw mills and finish mills wear out fast. Cyclones and separators face constant abrasion. The tiles are essential linings here. They withstand the grinding environment. Other industries benefit too. Chemical processing uses them for corrosive zones. Foundries apply them where molten metal flows.

The special shapes are important. They fit complex curves and surfaces easily. This ensures complete coverage. It prevents gaps where wear starts. Installation is straightforward. Cut them with diamond tools. Glue them directly onto surfaces using epoxy or cement. This creates a strong, lasting shield.

The result is clear. Equipment lasts much longer. Downtime for repairs drops sharply. Production runs smoother. Operating costs decrease. The high alumina content ensures top performance. It delivers unmatched wear resistance.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block

What makes Special Shape Alumina Ceramic Tile Block different?

It uses 99.7% pure Al2O3. This purity means very high hardness. It also means excellent wear resistance. This material handles extreme conditions well.

How hot can this alumina ceramic tile handle?

It handles very high temperatures. Continuous use is safe up to 1650°C (3000°F). Short spikes won’t damage it. This makes it good for furnaces and kilns.

Will chemicals damage this ceramic tile?

It resists many chemicals well. Strong acids and strong alkalis generally don’t harm it. Most organic solvents won’t affect it. This is good for chemical plants.

Can you machine this ceramic block after firing?

Machining after firing is very hard. The material is extremely tough. Grinding is possible but costly and slow. Design the shape correctly before firing. Plan the dimensions carefully upfront.

Is this tile better than metal for wear?

Yes, much better in many cases. The alumina ceramic is harder than most metals. It resists abrasion far better. It lasts much longer in gritty or sliding wear situations.

(Special Shape 99.7% Al2o3 Alumina Ceramic Tile Block)

REQUEST A QUOTE

RELATED PRODUCTS

Factory Supply Low 99%Al2O3 Parts Alumina Block Insulating Ceramic Socket

High Abrasion Resistance Electronic Insulating Al2O3 Ceramic 99 Alumina Block/Plate

High Temperature Resistant 99.5% White Fused Grinding Ceramic Block Al2o3 Alumina 99% Grating Plate

Polished Al2O3 Ceramic Plate Alumina Square Block

High Purity 99% Alumina Ceramic Blocks Protective Ceramic Tiles Al2O3 Structural Parts