Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

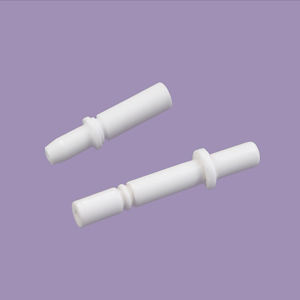

Overview of Alumina Ceramics PIN and SPOUT for Aluminum Tundish

Alumina Ceramics PIN and SPOUT for Aluminum Tundish is precision-engineered components made from high-purity aluminum oxide (Al₂O₃), offering superior mechanical strength, thermal stability, and electrical insulation. These pins are widely used in electronics, semiconductor equipment, medical devices, and industrial machinery where extreme durability and precision are required. With excellent wear and corrosion resistance, they ensure long-lasting performance in demanding environments.

Features of Alumina Ceramics PIN and SPOUT for Aluminum Tundish

Extreme Hardness & Wear Resistance – Ideal for high-friction applications

High-Temperature Stability – Withstands up to 1600°C without degradation

Excellent Electrical Insulation – Perfect for electronic and semiconductor uses

Chemical & Corrosion Resistance – Resists acids, alkalis, and harsh chemicals

Precision Machining – Tight tolerances for critical applications

(Alumina Ceramics PIN and SPOUT for Aluminum Tundish)

Specifications of Alumina Ceramics PIN and SPOUT for Aluminum Tundish

Alumina ceramics PIN and SPOUT are essential parts for aluminum tundish procedures. They control liquified metal flow during spreading. These parts are made from high-purity alumina product. This provides excellent resistance to warm. They manage severe temperature levels in the tundish setting. Their structure stays steady even at over 1600 degrees Celsius. Thermal shock resistance is strong. They withstand fast heating and cooling cycles without fracturing. Use resistance is one more crucial attribute. Molten aluminum causes little disintegration. This extends the parts’ functioning life. Chemical security is vital. Alumina does not respond with liquified light weight aluminum. This stops contamination of the steel. Smooth surfaces are guaranteed. This reduces turbulence in the steel stream. It likewise decreases the chance of obstructing. The PIN fits specifically right into the SPOUT. This develops a tight seal. Leaks are stayed clear of throughout putting. Dimensions are customizable. Typical PIN diameters vary from 20mm to 80mm. SPOUT lengths vary from 150mm to 500mm. Wall surface thickness is consistent for durability. Exact sizes match certain tundish layouts. Setup is simple. The components slot right into existing tundish arrangements. No unique devices are required. Upkeep is minimal. Normal visual checks guarantee they function correctly. Substitute is simple throughout arranged quits. Efficiency advantages consist of steady steel circulation. This boosts casting high quality. Downtime reduces since failings are unusual. Manufacturing performance rises. Operators save on constant component modifications. General costs go down with longer component life. These porcelains surpass conventional products. Steel or refractory parts wear faster. Alumina lasts several times longer. This makes them a clever financial investment for light weight aluminum plants.

(Alumina Ceramics PIN and SPOUT for Aluminum Tundish)

Applications of Alumina Ceramics PIN and SPOUT for Aluminum Tundish

Alumina ceramics PIN and SPOUT components are important for aluminum tundish procedures. They manage the rough conditions near liquified aluminum. The PIN manages the metal circulation rate entering the mold and mildew. The SPOUT overviews the liquified aluminum stream properly. Both components encounter extreme heat and chemical assault. Alumina ceramic offers the right properties for this job.

This ceramic holds up against very high temperatures quickly. It doesn’t soften or melt in the tundish environment. Thermal shock resistance is an additional essential advantage. The PIN and SPOUT experience rapid temperature level adjustments. Alumina ceramic manages these abrupt shifts without breaking. This reliability prevents harmful leaks and expensive downtime.

Resistance to erosion and deterioration is essential. Molten light weight aluminum circulation is rough. Alumina ceramic is very tough. It resists wear from the consistent metal stream. The material also withstands chemical attack from molten light weight aluminum and fluxes. This indicates the PIN and SPOUT maintain their form and feature much longer. They maintain consistent circulation control over time.

Purity is crucial for top notch aluminum castings. Alumina ceramic is really inert. It does not respond with the liquified metal. It does not present undesirable pollutants. This ensures the light weight aluminum remains clean. Regular flow control from the ceramic parts also enhances casting quality. It reduces flaws in the final product.

Using alumina ceramic PIN and SPOUT parts brings genuine advantages. They last much longer than standard products. This lowers just how frequently you need replacements. Much less downtime implies better manufacturing performance. Reduced upkeep costs boost overall operational business economics. The resilience and efficiency of alumina porcelains make them the smart option for demanding aluminum tundish applications. They directly support smoother, more reliable spreading processes.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Ceramics PIN and SPOUT for Aluminum Tundish

Alumina Ceramics PIN and SPOUT FAQs for Aluminum Tundish

What are alumina ceramics pins and spouts?

These are special parts made from a very hard ceramic material. They control the flow of molten aluminum inside the tundish. The pin plugs the hole. The spout guides the metal out. They work together.

Why use alumina ceramic for these parts?

Alumina ceramic handles extreme heat very well. Molten aluminum is extremely hot. This material stays strong. It doesn’t melt. It doesn’t crack easily. It also resists wear from the flowing metal. This means the parts last longer.

How long do these pins and spouts typically last?

Their lifespan depends on the casting conditions. Things like temperature and metal flow speed matter. Generally, they last much longer than parts made from other materials. This reduces how often you need to change them. It saves time and money.

Can they handle the high temperatures in the tundish?

Yes. That is a key reason they are used. Alumina ceramic keeps its strength even above 1700°C. The tundish temperature is usually lower. This gives a big safety margin. The parts stay reliable.

How do I know if a pin or spout needs replacing?

Look for signs of wear or damage. Check the sealing surface of the pin. See if it’s worn down. Inspect the spout bore. Look for erosion or cracking. Uneven metal flow can also signal a problem. Replace parts before they fail completely. This prevents leaks or interruptions.

(Alumina Ceramics PIN and SPOUT for Aluminum Tundish)

REQUEST A QUOTE

RELATED PRODUCTS

Diesel Heater Ceramic Ignition Electrode Pin Alumina Ceramic Igniter Spark Plug

Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter

96% Al2O3 Alumina Ceramic Tube Ceramic Pin Ceramic Ring for High Temperature Application

CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing

Good quality 95% alumina ceramic ignition needle/pin for gas oven/cooker/stove