Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

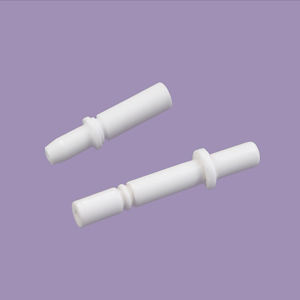

Overview of CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing

CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing is precision-engineered components made from high-purity aluminum oxide (Al₂O₃), offering superior mechanical strength, thermal stability, and electrical insulation. These pins are widely used in electronics, semiconductor equipment, medical devices, and industrial machinery where extreme durability and precision are required. With excellent wear and corrosion resistance, they ensure long-lasting performance in demanding environments.

Features of CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing

Extreme Hardness & Wear Resistance – Ideal for high-friction applications

High-Temperature Stability – Withstands up to 1600°C without degradation

Excellent Electrical Insulation – Perfect for electronic and semiconductor uses

Chemical & Corrosion Resistance – Resists acids, alkalis, and harsh chemicals

Precision Machining – Tight tolerances for critical applications

(CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing)

Specifications of CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing

Our custom-made CNC turned alumina ceramic overview pins supply precision and dependability for demanding commercial jobs. Alumina ceramic is extremely hard. It stands up to wear remarkably well. These pins manage serious rubbing and abrasion daily. They keep their shape and size much longer than steel choices. This saves you cash on substitutes and downtime.

Alumina ceramic is chemically inert. Our pins won’t rust or corrosion. They work perfectly in severe chemical settings. They additionally handle extremely high temperatures easily. Warm won’t warp or degrade them. This stability is crucial for regular performance.

We make these guide pins to your specific needs. Specify the diameter, size, and general form. We equipment them precisely making use of innovative CNC turning. We achieve tight dimensional tolerances. Inform us the specific fit you require. We provide it. Common diameters vary from 1mm up to 30mm or even more. Lengths vary likewise.

Surface area finish matters. A smooth finish decreases rubbing better. We provide numerous surface area roughness degrees. Specify your desired Ra worth. We can attain really great surfaces. We likewise give options like chamfered or radiused edges. This protects against cracking throughout installation and usage.

Material purity is high grade. We use 99.5% alumina ceramic or higher. This makes certain excellent mechanical properties. It ensures consistent performance batch after set. The pins include high electrical insulation. They are excellent for digital applications.

Personalized features are available. Required a particular head form? Call for a flat or a threaded end? Need a center opening? We maker these information properly. Our procedure manages intricate geometries accurately. Each pin is checked thoroughly. We examine measurements, surface quality, and integrity. You obtain components that carry out.

(CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing)

Applications of CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing

Precision CNC turned alumina ceramic overview pins resolve difficult commercial troubles. These personalized components manage severe conditions much better than metal or plastic. Alumina ceramic deals vital advantages. It withstands extreme warm. It stays hard under hefty wear. It blocks electricity completely. It remains chemically steady around severe compounds. Customized manufacturing implies best suitable for your makers.

Semiconductor manufacturers rely upon these pins. They position silicon wafers specifically throughout etching and deposition. The ceramic won’t infect sensitive chips. It survives hostile cleaning chemicals. Its smooth surface prevents wafer scratching. Accuracy turning makes certain flawless positioning whenever.

Automotive manufacturing uses these pins heavily. They guide parts accurately in high-speed welding robotics and assembly jigs. The ceramic withstands stimulates and warmth from welding. It does not use down promptly. This means less downtime for replacements. Consistent accuracy keeps production line running efficiently.

Medical gadget building contractors need biocompatible materials. Alumina ceramic fits completely. It does not react with body liquids or cleansing agents. CNC transforming produces complex pin forms for surgical tools and diagnostic equipments. The product remains sterile conveniently. Its stamina sustains delicate procedures.

Industrial automation benefits substantially. These pins assist robotic arms and setting up components dependably. They sustain continuous rubbing and influence. Their electrical insulation avoids brief circuits. Personalized shapes and sizes fit one-of-a-kind machine designs precisely. This lowers resonance and imbalance problems. Manufacturing facilities see far better item quality and less device wear.

Optics and laser systems demand stability. Alumina ceramic overview pins setting lenses and mirrors without shifting. They manage laser heat without bending. Their non-magnetic nature prevents disturbance. Precise CNC transforming supplies the precise tolerances required for clear emphasis and beam of light placement.

Food and packaging equipment needs sanitary components. Alumina ceramic stands up to deterioration from acids and cleaning up solutions. Its non-porous surface quits germs growth. Custom-made pins guarantee smooth, reliable procedure in damp, requiring atmospheres. They last much longer than stainless-steel oftentimes.

CNC turning allows complex geometries. We make straight pins, stepped pins, pins with unique grooves or flanges. Surface area surfaces get customized for low rubbing or limited seals. Every pin matches your specific illustration specs. This personalization resolves specific application challenges. You obtain components built precisely for your equipment’s demands.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing

Here are 5 FAQs about CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing:

What are alumina ceramic guide pins?

Alumina ceramic guide pins are precision components. They position parts in machinery. These pins handle high wear and heat. Industries like electronics and automotive use them.

Why pick CNC turning for these pins?

CNC turning gives exact shapes and tight tolerances. It machines hard alumina ceramic efficiently. This method ensures consistency for custom orders. It fits complex designs well.

What benefits do alumina ceramic pins offer?

Alumina ceramic resists wear extremely well. It handles high temperatures. These pins won’t rust or react with chemicals. They last longer than metal pins. They reduce machine downtime.

Can you make custom sizes and shapes?

Yes. We create any size or shape you need. Provide your drawings or specifications. We use CNC turning to match them. Small or large batches work.

How do you check pin quality?

We measure every pin with precision tools. We check dimensions and surface finish. We test hardness and strength. This ensures each pin meets strict standards.

(CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing)

REQUEST A QUOTE

RELATED PRODUCTS

Customised 3-Pin Ceramic Alumina Electrodes, Electro-ceramics for Gas Burners

Diameter 0.8* Length 6 mm 99.5 % Hard Ceramic Al2o3 Alumina Ceramic Rod Alumina Pin

High Quality Custom Gas Boiler 95%alumina Ceramic 16511Ignition Needle Pin

Abrasive Customized Size 96% 99% Alumina Ceramic Rod Stick Pin in Stock Factory

Good quality 95% alumina ceramic ignition needle/pin for gas oven/cooker/stove