Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

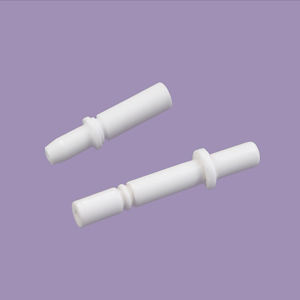

Overview of Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing

Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing is precision-engineered components made from high-purity aluminum oxide (Al₂O₃), offering superior mechanical strength, thermal stability, and electrical insulation. These pins are widely used in electronics, semiconductor equipment, medical devices, and industrial machinery where extreme durability and precision are required. With excellent wear and corrosion resistance, they ensure long-lasting performance in demanding environments.

Features of Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing

Extreme Hardness & Wear Resistance – Ideal for high-friction applications

High-Temperature Stability – Withstands up to 1600°C without degradation

Excellent Electrical Insulation – Perfect for electronic and semiconductor uses

Chemical & Corrosion Resistance – Resists acids, alkalis, and harsh chemicals

Precision Machining – Tight tolerances for critical applications

(Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing)

Specifications of Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing

We make custom CNC turned alumina ceramic overview pins precisely to your illustrations. This product is exceptionally hard. It withstands wear exceptionally well. These pins deal with high heat uncreative. They perform dependably in temperatures up to 1600 ° C. Electrical insulation is one more crucial advantage. Alumina ceramic does not perform power. Chemical resistance is outstanding. These pins hold up against harsh acids and bases. They won’t rust or weaken quickly.

Dimensional accuracy is critical. Our CNC transforming procedure assurances exact sizes. We satisfy tight resistances per your specifications. Surface surface is constantly smooth. We achieve a surface area roughness of Ra 0.4 μm optimum. This makes sure very little rubbing throughout operation. The pins slide efficiently in their applications. Customized shapes and functions are feasible. We maker grooves, damages, strings, and particular pointer profiles. Your illustration dictates the last geometry.

Product pureness is high. We utilize premium 99.5% alumina ceramic. This ensures constant homes and performance. The pins are very strong. They supply high mechanical strength and tightness. Brittleness is an element. Take care of these pins meticulously throughout setup. Prevent impact loading. Color is usually white or ivory. Particular color requests can sometimes be suited. We thoroughly evaluate each pin. We verify measurements, surface top quality, and visual issues.

(Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing)

Applications of Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing

Custom-made CNC transformed alumina ceramic guide pins built to your exact illustrations address hard industrial problems. These pins are really hard. They resist wear exceptionally well. They remain smooth for a long period of time. This merciless run much longer without picking up solutions.

Semiconductor factories require these pins. They take care of aggressive chemicals. They work in very clean spaces. They maintain devices aligned perfectly throughout chip making. This protects against expensive errors. Automotive production lines count on them as well. They guide components with welding and paint. They do not flex or break like metal pins. This keeps vehicle assembly exact and quick.

Food and medication makers pick these ceramic pins. They will not corrosion or react with items. They satisfy stringent tidiness guidelines. They work safely in damp or chemical cleansing areas. Medical device home builders use them in assembly devices. They are biocompatible. They guarantee accurate positioning of little components.

Electronic devices factories created motherboard with these guide pins. They protect versus electricity. They stop shorts. They place delicate components exactly right every single time. These pins deal with heats quickly. Furnace devices utilizes them for alignment. They do not warp or compromise with warmth. Metal pins would stop working quickly.

These custom ceramic pins fit your device completely. They are made exactly like your drawing claims. This gets rid of play and wobble. Your equipment runs smoother and makes better products. They last a lot longer than steel pins. You conserve cash on substitutes and downtime.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing

Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing: 5 FAQs

What material is used? Why alumina ceramic?

We use high-purity alumina ceramic (Al2O3). This material is very hard. It resists wear extremely well. Alumina ceramic handles high temperatures easily. It is electrically insulating. It resists corrosion from chemicals. These properties make it perfect for demanding guide pin jobs. Metal pins wear out faster.

How precise can you make these guide pins?

We achieve high precision. Our CNC turning machines are very accurate. We routinely hold tolerances within +/- 0.01 mm. We can hit tighter tolerances if your drawing requires it. Tell us the exact dimensions you need. We machine the pins exactly to your specifications.

What surface finish is possible?

We offer different surface finishes. The standard finish is very smooth. We measure it as Ra 0.2 micrometers or better. We can provide a mirror polish if needed. A smoother finish reduces friction. It helps prevent wear on the pin and the mating part. Specify your required roughness on the drawing.

Can you make pins to my exact drawing?

Yes. Customization is our focus. Send us your detailed technical drawing. We need dimensions, tolerances, surface finish, and any special features. We machine the alumina ceramic pin precisely according to your drawing. We accommodate unique shapes, grooves, undercuts, or specific chamfers. Your drawing guides the entire process.

What is the typical lead time?

Lead time depends on order quantity and complexity. Simple designs in small batches take about 2-3 weeks. Larger orders or complex geometries need more time. We program the machines specifically for your part. We also do thorough quality checks. We give you a firm timeline after reviewing your drawing. We ship promptly when finished.

(Custom CNC Turned Alumina Ceramic Guide Pin According to Drawing)

REQUEST A QUOTE

RELATED PRODUCTS

Customized 95% Al2O3 Igniter Probe Gas Oven Part Alumina Ceramic Spark Plug Ignition Electrode Pin

Aulipur High Density Alumina Ceramic Terminal Block 6mm² Cable Connector 2 Pin Connector 6A High Temperature Resistant 1000

Multi-Sizes Alumina Zirconia Silicon Nitride Ceramic Dowel Pins High Temperature Resistance 20-Year From China

Alumina Ceramic Custom Design Wear-resistance Al2o3 Ceramic Dowel Pin

CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing