Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

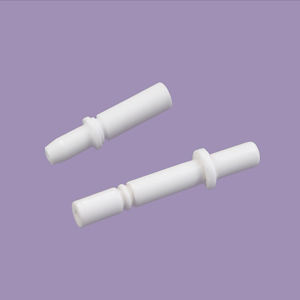

Overview of Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner

Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner is precision-engineered components made from high-purity aluminum oxide (Al₂O₃), offering superior mechanical strength, thermal stability, and electrical insulation. These pins are widely used in electronics, semiconductor equipment, medical devices, and industrial machinery where extreme durability and precision are required. With excellent wear and corrosion resistance, they ensure long-lasting performance in demanding environments.

Features of Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner

Extreme Hardness & Wear Resistance – Ideal for high-friction applications

High-Temperature Stability – Withstands up to 1600°C without degradation

Excellent Electrical Insulation – Perfect for electronic and semiconductor uses

Chemical & Corrosion Resistance – Resists acids, alkalis, and harsh chemicals

Precision Machining – Tight tolerances for critical applications

(Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner)

Specifications of Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner

This Electric Alumina Porcelain Industrial Ignition Pin triggers gas appliances accurately. It fits gas ovens and gas infrared burners. Alumina ceramic is the core material. This ceramic takes care of extreme warm well. It endures temperatures over 1500 ° C. This prevents breaking or thawing near flames. The ceramic also shields power completely. High voltage travels through securely. This prevents dangerous shorts.

The pin creates a strong stimulate. It sparks gas mixtures promptly. Regular ignition is vital for heater effectiveness. This ignition pin functions reliably in tough problems. It resists thermal shock from rapid heating & cooling. Industrial cooking areas need this durability. The ceramic product is really hard. It withstands wear and abrasion in time. This implies the pin lasts long. Substitute happens less typically.

Moisture and chemicals prevail issues. The alumina ceramic surface area battles corrosion. Humidity or cleaning representatives don’t damage it quickly. This makes sure dependable performance in moist locations. Various versions exist for numerous appliances. Pin size and size differ. Typical sizes are readily available. The threaded metal base provides a safe and secure fit. Setup is uncomplicated. Inspect your devices’s demands prior to buying.

This ignition pin delivers high voltage effectively. It attaches straight to your ignition system. The stimulate space is specific. This creates the ignition trigger right where required. Great electrical insulation is crucial. It keeps the spark concentrated. Energy isn’t squandered. Users obtain reliable ignition every cycle. This minimizes fell short starts and gas waste. The design focuses purely on function.

(Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner)

Applications of Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner

Alumina ceramic ignition pins are vital parts in numerous gas home appliances. They develop triggers to accurately light gas. These pins are made from extremely pure ceramic. This product manages extreme conditions well. Gas ovens make use of these ignition pins regularly. Every time you switch on the stove, the pin stimulates. It lights the burner rapidly. This ceramic component sits right inside the warm heater area. Routine products would certainly fail right here. Alumina ceramic withstands the intense warmth. It additionally withstands abrupt temperature level changes without fracturing. This is thermal shock resistance. It’s vital for stove igniters.

Infrared burner also depend upon these ceramic pins. These burners warmth points fast in restaurants or factories. The ignition pin should stimulate reliably under high induction heat. Alumina ceramic supplies excellent electric insulation. This stops harmful electric shorts near the gas. It keeps the stimulate strong and regular. The tough ceramic surface area stands up to wear from the triggering itself. This makes the pins last much longer.

Industrial furnace need hard ignition components. Assume big central heating boilers or procedure heaters. These systems run for lengthy hours. Ignition should function each and every single time. Alumina ceramic pins provide this reliability. They manage high voltage triggers without damaging down. Their resistance to chemical rust is one more large and also. Severe commercial environments do not harm them quickly. This lowers maintenance expenses and downtime. These pins are just extra sturdy than older types. They offer much better performance gradually. You obtain trusted ignition for gas stoves, infrared heaters, and huge commercial burners.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner

What is an electrical alumina ceramic ignition pin? This pin ignites gas in ovens and infrared burners. It creates sparks to start flames. Alumina ceramic makes it strong against heat and wear. It replaces metal pins in many appliances.

How does the ignition pin work? Electricity flows to the pin tip. A spark jumps across a small gap. This spark lights the gas. The process is quick and reliable.

Why choose alumina ceramic material? Alumina ceramic handles extreme heat. It resists corrosion and cracking. It insulates electricity safely. This material lasts longer than metal.

Where is this ignition pin used? It fits home gas ovens. It works in restaurant equipment. Industrial infrared heaters use it too. Commercial baking systems need it.

How long does the ignition pin last? It typically serves for years. Proper installation helps durability. Harsh conditions might shorten its life. Regular checks prevent unexpected failures.

(Electrical Alumina Ceramic Industrial Ignition Pin for Gas Oven&Gas Infrared Burner)

REQUEST A QUOTE

RELATED PRODUCTS

Diameter 0.8* Length 6 mm 99.5 % Hard Ceramic Al2o3 Alumina Ceramic Rod Alumina Pin

Surface Polished Industrial Alumina Ceramic Pins 99% Al2O3 Rod

Al2O3 Alumina Ceramic Guide Pin for Spot Welding

Good quality 95% alumina ceramic ignition needle/pin for gas oven/cooker/stove

CNC Turned Alumina Ceramic Guide Pin Custom Manufacturing