Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

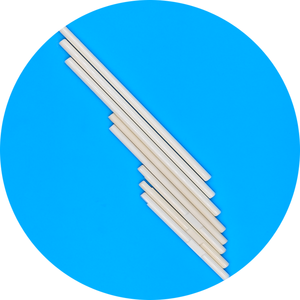

Overview of Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter

Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter is precision-engineered components made from high-purity aluminum oxide (Al₂O₃), offering superior mechanical strength, thermal stability, and electrical insulation. These pins are widely used in electronics, semiconductor equipment, medical devices, and industrial machinery where extreme durability and precision are required. With excellent wear and corrosion resistance, they ensure long-lasting performance in demanding environments.

Features of Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter

Extreme Hardness & Wear Resistance – Ideal for high-friction applications

High-Temperature Stability – Withstands up to 1600°C without degradation

Excellent Electrical Insulation – Perfect for electronic and semiconductor uses

Chemical & Corrosion Resistance – Resists acids, alkalis, and harsh chemicals

Precision Machining – Tight tolerances for critical applications

(Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter)

Specifications of Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter

The Electrode 95% Alumina Ceramic Ignition Needle Pin uses 95% Alumina (Al2O3). This material supplies high performance. It endures extreme temperatures. It withstands thermal shock. This makes certain reliability in hard problems. The ceramic deals exceptional electric insulation. It protects against present leak. This keeps operations secure. Mechanical stamina is high. It resists wear. It deals with physical stress well. Corrosion resistance is strong. It withstands harsh chemicals. It lasts longer in corrosive settings.

This element acts as a spark igniter. It generates sparks efficiently. It ignites fuel mixes reliably. Applications consist of gas devices. It works in industrial heaters. It fits auto ignition systems. The layout is precise. It delivers regular triggering. Setup is simple. Upkeep requirements are reduced.

The alumina ceramic has reduced porosity. This quits gas infiltration. It avoids electric failings. Temperature tolerance gets to 1600 ° C. It maintains structural integrity. It keeps a secure stimulate gap. Chemical inertness is essential. It does not react with gas. Performance remains stable in time.

Personalized sizes are readily available. Criterion dimensions fit most systems. Surface level of smoothness decreases carbon accumulation. This makes certain clean stimulates. Consistent ignition results. This part is vital for system functionality. It suits home devices. It serves industrial machinery. It operates in vehicle engines.

Long life span lowers substitutes. It decreases maintenance costs. It enhances system performance. Engineers prefer this product. It is a cost-effective solution.

(Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter)

Applications of Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter

This alumina ceramic ignition pin manages extreme heat well. It’s the core element in lots of spark-based systems. Its major job is producing trusted triggers continuously. The 95% alumina formula gives it remarkable resilience. This product endures very high temperatures without weakening. It also stands up to electrical wear gradually. Corrosion from chemicals or gases does not impact it much.

You discover these pins in cars and truck and motorbike engines. They rest within ignition system. The ceramic insulator maintains the stimulate concentrated. It quits electricity from dripping. This makes sure a strong spark every time the engine cycles. Gas engines depend on this consistent ignition.

Industrial setups utilize these pins heavily too. Gas-powered heating systems and central heating boilers count on them. Huge burners for heater need reputable starters. The ceramic pin sparks reliably also in harsh atmospheres. Stoves and kilns frequently utilize them for pilot burner. Consistent ignition is critical for safety and efficiency.

Home devices benefit from this innovation. Gas ranges, stoves, and grills use these igniters. Pressing the knob or transforming it clicks the igniter. The ceramic pin generates the trigger lighting the heater. Its strength means it lasts for several years consistently. Hot water heater and fire places additionally utilize comparable ignition systems.

Other applications exist. Lantern lighters and particular welding equipment use these pins. Any kind of gadget requiring a precise, hot trigger usually picks alumina ceramic. The product’s security under heat is unrivaled. It provides electric isolation precisely where needed. This makes ignition much safer and more dependable throughout lots of usages. Performance under anxiety defines its value.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter

What is the ignition needle made of? The ignition needle uses 95% alumina ceramic. This material is aluminum oxide, called Al2O3. It is a hard ceramic substance. It handles tough conditions well.

Why choose 95% alumina ceramic? This ceramic grade handles extreme heat. It resists wear over time. It stops corrosion effectively. It insulates electricity perfectly. These traits ensure reliable sparks. They prevent electrical leaks.

How does it work? The needle sits inside the igniter. Electricity flows to its tip. A spark jumps across a gap. This spark lights fuel mixtures. Combustion starts quickly. It powers devices like heaters or engines.

What are the main benefits? The needle lasts longer than metal versions. It survives high temperatures without damage. It avoids rust and corrosion. Sparks happen consistently. This reduces maintenance needs. It cuts replacement costs too.

Where is it typically used? This part fits gas appliances. Examples are home ovens and boilers. It works in industrial burners. It serves in heating systems. Any device needing ignition sparks uses it.

(Electrode 95% Alumina Ceramic Ignition Needle Pin Al2o3 Spark Plug Ceramic Igniter Spark Igniter)

REQUEST A QUOTE

RELATED PRODUCTS

Refractory Ceramic Alumina Ceramic Flange Pin

Ceramic Punch Alumina Ceramic Punch Pins CNC for Electronics

Industrial Alumina Ceramic 3 Needles Type Electric Ignition Rods Spark Ignition Pin

Surface Polished Industrial Alumina Ceramic Pins 99% Al2O3 Rod

Alumina Ceramic Rods Factory Direct ing 99.8% Alumina Al2O3 Zirconia Ceramic Solid Pins Rods