Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

Overview of 99 High Purity Alumina Ceramic Piston Plunger for Valve

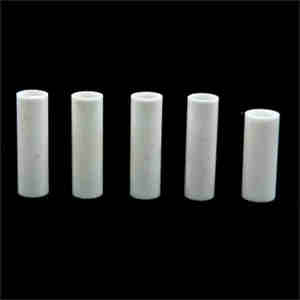

99 High Purity Alumina Ceramic Piston Plunger for Valve is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of 99 High Purity Alumina Ceramic Piston Plunger for Valve

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(99 High Purity Alumina Ceramic Piston Plunger for Valve)

Specifications of 99 High Purity Alumina Ceramic Piston Plunger for Valve

This bettor makes use of 99% pure alumina ceramic. It delivers outstanding performance in demanding valve applications. The high purity guarantees superb chemical resistance. It holds up against severe acids and alkalis effectively. Its severe solidity minimizes wear substantially. This firmness offers it a long life span. You obtain reputable operation with time. The material thickness is really high. This gives premium dimensional security. It holds its shape well under stress. The surface area finish is incredibly smooth. This lessens rubbing during procedure. Smooth procedure decreases energy requirements. It additionally prevents fragment accumulation.

Typical dimensions include different sizes and lengths. Common sizes vary from 5mm to 30mm diameter. Requirement lengths are 20mm to 100mm. Custom dimensions are easily available. We equipment parts precisely to your illustrations. Limited tolerances are conventional. We accomplish tolerances within +/- 0.01 mm. This makes sure a best suit your shutoff setting up. Consistent performance depends upon precision.

This plunger takes care of high temperatures conveniently. It works dependably approximately 1600 degrees Celsius. Thermal shock resistance is great. Sudden temperature adjustments trigger very little tension. It preserves stamina under thermal biking. Mechanical strength goes over. Compressive toughness surpasses 2500 MPa. This handles high pressure loads efficiently. It resists fracturing under stress. Electric insulation homes are superb. This stops existing leakage problems. Dielectric stamina is really high.

Utilize this plunger where abrasion or rust destroys metal parts. It excels in chemical pumps and metering valves. Water treatment systems benefit substantially. Drug processing requires its purity. Semiconductor manufacturing requires its inertness. High-purity liquid control demands this dependability. Change metal bettors failing from wear or rust. This ceramic remedy uses unmatched toughness. It lowers maintenance regularity and prices.

(99 High Purity Alumina Ceramic Piston Plunger for Valve)

Applications of 99 High Purity Alumina Ceramic Piston Plunger for Valve

99% pure alumina ceramic piston bettors resolve tough troubles in shutoffs. This material is extremely hard. It withstands wear much better than steel. Valves face constant rubbing. Components massage with each other during operation. Steel plungers wear down promptly. Ceramic plungers last much longer. This reduces upkeep prices. Downtime lowers too.

The high pureness issues. Impurities damage ceramic. 99% alumina is really dense. Density stops leaks. It stops fluids or gases from permeating with the plunger itself. This makes certain tight seals. Valve performance stays trustworthy. Pressure control continues to be precise.

Chemical resistance is an additional huge and also. Many industrial procedures make use of severe chemicals. Acids, bases, and solvents attack steel. High purity alumina shrugs them off. This avoids corrosion damage. Valves keep functioning safely in chemical plants, semiconductor fabs, and wastewater therapy.

High temperatures are not a problem either. Alumina ceramic takes care of severe warmth without flawing. It does not soften like some plastics or alloys. Shutoffs in engines, heating systems, or power generation require this security. Performance remains constant under thermal stress and anxiety.

These bettors work well where sanitation is critical. They do not infect fluids. Bits will not flake off. This is important for medical gadgets, food handling devices, and pharmaceutical production. Sterile conditions are kept.

High purity alumina is additionally electrically shielding. It prevents stray currents. This shields delicate electronics close by. Shutoffs in analytical instruments or electrical systems advantage. Dependability enhances.

Valves manage circulation sought after circumstances. Think oil and gas exploration. Abrasive slurries use components quickly. Ceramic plungers sustain the sand and grit. Mining operations see similar difficulties. Pump valves last longer with ceramic components.

Water treatment plants use these plungers. They withstand chlorine and various other disinfectants. Municipal water supply stay reliable. Desalination plants battling salt rust rely upon them also. Marine applications get from the deep sea resistance.

Precision tools like chromatography systems require ultra-reliable valves. Tiny leakages destroy outcomes. The dimensional stability and tight seals of 99% alumina plungers provide. Laboratory precision relies on regular valve feature.

Automotive gas injectors are an additional vital area. Exact gas metering demands marginal wear. Ceramic bettors preserve tight tolerances with time. Engine performance stays high. Emissions remain reduced.

The non-stick surface area assists too. Sticky materials will not hold on to the ceramic. Shutoffs handling adhesives, paints, or viscous oils operate efficiently. Clogging threats lower. Circulation control is more predictable.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99 High Purity Alumina Ceramic Piston Plunger for Valve

What is this plunger made of?

It uses 99% pure alumina ceramic. This material gives top performance. Alumina ceramic is very hard. It resists wear extremely well.

Why choose alumina ceramic?

Alumina ceramic beats metal plungers. It handles tough chemicals easily. Acids and bases don’t damage it. High temperatures cause no problem. It stays strong under heat. Metal plungers often fail here.

How long does this plunger last?

It lasts much longer than metal parts. The ceramic surface is very smooth. Friction stays low. Wear happens slowly. You get reliable service life. Downtime drops significantly.

Where is this plunger used?

It fits tough valve jobs. Chemical pumps need it. Semiconductor equipment uses it. Pharmaceutical machines rely on it. Any place needing pure, non-contaminating parts. It keeps fluids clean.

What sizes are available?

Many sizes exist. Standard diameters range from small to large. Custom sizes are possible too. We match your valve specs exactly. Tell us your requirements. We make it fit.

(99 High Purity Alumina Ceramic Piston Plunger for Valve)

REQUEST A QUOTE

RELATED PRODUCTS

Top Fashion Electric Muffle Furnace Alumina Tube Shaft Refractory & Nozzle Precision Ceramic Plunger Sleeve

High Precision Ivory Al2O3 Alumina Ceramic Machinery Plunger Shaft Piston

High Pressure Mud Pump Wear Resistance 99% Alumina Ceramic Rotary Plunger

95% 99% Alumina Ceramic Piston Plunger With Metal

High Purity 95% 99% Alumina Ceramic Plunger Al2O3 Ceramic Pump Piston