Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

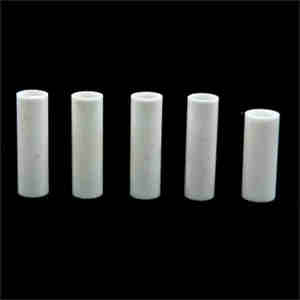

Overview of Ceramic Piston Pump Alumina Plunger Rod

Ceramic Piston Pump Alumina Plunger Rod is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of Ceramic Piston Pump Alumina Plunger Rod

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(Ceramic Piston Pump Alumina Plunger Rod)

Specifications of Ceramic Piston Pump Alumina Plunger Rod

This ceramic piston pump uses a high-performance alumina plunger pole. Alumina is a really difficult ceramic material. Its hardness is near the top of the Mohs range. This severe solidity gives the bettor rod excellent resistance to put on. It lasts much longer than steel poles in unpleasant conditions. The smooth surface area of the alumina rod reduces friction inside the pump. Much less rubbing means much less power loss. Much less friction likewise suggests less heat accumulates.

The alumina ceramic resists chemical strike quite possibly. It deals with hard chemicals like acids and antacids without damages. This rust resistance is much better than stainless-steel. The rod remains secure under high stress. It doesn’t deform or bend. This stability keeps the pump functioning effectively. The alumina product doesn’t respond with the fluids being pumped. It maintains the liquid pure. This is important for delicate applications.

These pumps work well moving challenging liquids. They manage fluids with fine bits or slurries. They deal with corrosive chemicals securely. Common usages consist of commercial chemical handling devices. They are used in water treatment systems. They are discovered in accurate laboratory tools. They operate in requiring clinical gadgets.

The plunger pole is made from high-purity alumina ceramic. Its common hardness is over 85 HRA. Its surface area finish is really smooth. The pole diameter is specifically machined. Typical sizes range from 6mm to 25mm. Stroke sizes vary based on the pump version. The ceramic pole is placed firmly in a steel pump real estate. Usual housing materials are stainless-steel or specialized alloys. The pump layout minimizes dead volume. This guarantees efficient fluid displacement. Pressure rankings depend upon the particular pump dimension and design. Circulation rates are adjustable. They depend on the pump speed and stroke settings.

(Ceramic Piston Pump Alumina Plunger Rod)

Applications of Ceramic Piston Pump Alumina Plunger Rod

Ceramic piston pumps move fluids efficiently in hard setups. The alumina bettor rod is a crucial part inside these pumps. It presses versus seals to develop stress. This alumina pole offers major benefits over steel poles.

Alumina ceramic is exceptionally difficult. It withstands wear far better than steel. This means the bettor pole lasts far much longer. You replace it much less frequently. That conserves cash and downtime.

This ceramic takes care of high warmth well. It remains strong when things fume. Metal poles can deteriorate or warp with temperature level modifications. The alumina pole maintains functioning dependably.

Chemicals are no worry for alumina. It pokes fun at acids, bases, and solvents. Metal poles wear away or react with harsh liquids. The ceramic pole stays undamaged. This is vital for pumping chemicals securely.

The surface area of alumina is really smooth. This smoothness decreases rubbing inside the pump. Less rubbing implies less power lost. The pump runs cooler and much more efficiently. Seals likewise last longer with less wear.

Alumina ceramic is very rigid. It does not flex or bend under stress. This stiffness makes sure precise movement. The pump provides regular circulation and pressure. Performance remains stable in time.

These pumps are common where dependability matters most. You discover them in commercial makers, medical devices, and lab devices. They function well relocating distilled water, chemicals, or gas. Water therapy plants typically rely on them. The difficult alumina bettor pole makes these demanding applications possible. It handles the stress, the warmth, and the harsh fluids.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Ceramic Piston Pump Alumina Plunger Rod

Here are five common questions about ceramic piston pump alumina plunger rods:

What makes alumina ceramic good for plunger rods?

Alumina ceramic is extremely hard. This hardness fights wear effectively. The rod surface stays smooth much longer. A smooth rod surface helps the pump seal work better. It reduces leakage over time.

How well does it resist wear?

Alumina plunger rods handle wear far better than metal rods. They tolerate abrasive fluids much better. This means the pump needs less fixing. The pump parts last longer. You save money on replacements and downtime.

Will harsh chemicals damage the alumina rod?

Alumina ceramic resists most chemicals very well. Acids, alkalis, solvents usually don’t harm it. This makes it reliable for tough chemical jobs. Metal rods often rust or corrode in these situations. Alumina stays stable.

Does it handle heat well?

Yes, alumina ceramic handles high heat very effectively. It keeps its strength and shape at high temperatures. Metal rods can soften or warp with heat. This stability is vital for hot fluid pumping. It prevents pump failure.

Is maintenance different for alumina rods?

Alumina rods need less maintenance generally. Their hardness reduces wear and tear. Check seals regularly like any pump. But the rod itself rarely needs replacing. Handle it carefully during installation. Alumina is hard but can crack if hit hard.

(Ceramic Piston Pump Alumina Plunger Rod)

REQUEST A QUOTE

RELATED PRODUCTS

Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

Polishing Hard Strong Industrial Alumina Ceramic Round Ball Stick Plunger Piston

All-purpose wear-resistant, corrosion-resistant and high-temperature resistant alumina ceramic plunger

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Molding Ceramic Wear and Corrosion Resistant Alumina Ceramic Piston Plunger Bushing Rod for High Pressure Pump