Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

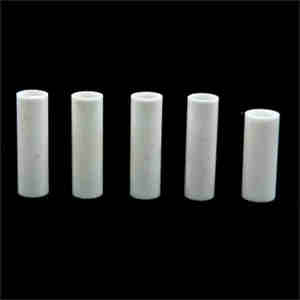

Overview of China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding

China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding)

Specifications of China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding

China makes 99% alumina ceramic parts for laborious. These parts are extremely hard. They resist use incredibly well. They deal with high warmth easily. Chemicals do not harm them. Power doesn’t travel through them. This makes them best for lots of commercial uses.

Take a look at alumina ceramic shafts and screws. They are strong and tight. They won’t flex a lot. They keep their shape under stress. They last a long time in makers. They are far better than steel in destructive places. They function well in pumps and shutoffs.

Alumina ceramic bettors are necessary for dosing pumps. They glide smoothly inside cylinders. They develop a limited seal. This gives really exact liquid control. They manage acids and solvents without corroding. They are dependable for chemical processing and medication production.

We also provide alumina ceramic tubes and rods. They come in numerous dimensions. Diameters range from 1mm to 50mm. Sizes are personalized. They are made use of for cutting guides. They lead laser beams accurately. They are utilized in soldering iron. They deal with the extreme warm. They are secure insulators in electronics.

These ceramic parts are made thoroughly. They are sintered at extremely high temperatures. This makes them thick and strong. We manage the measurements exactly. Tolerances are tight. Flatness is superb. Surface area finish is smooth. Sprucing up gets to Ra 0.2 microns. This minimizes rubbing. This prevents leaks. This boosts efficiency.

The material handles extreme problems. It operates in temperature levels over 1600 ° C. It endures high pressure. It stands up to thermal shock. Sudden temperature level changes don’t fracture it conveniently. It is perfect for extreme atmospheres. It is utilized in semiconductors, aerospace, and chemical plants. It offers lengthy life and low upkeep.

(China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding)

Applications of China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding

China’s 99% alumina ceramic parts are incredibly challenging. They take care of extreme conditions well. This makes them crucial for several demanding tasks. Think about shafts and screws. These ceramic versions are used in motors and pumps. They withstand put on better than metal. They take care of high temperatures without warping. They additionally stand up to chemical strike. This implies longer life and much less downtime in extreme manufacturing facilities. These parts are crucial where steel falls short quickly.

Plunger shutoffs and dosing pumps additionally benefit considerably. Alumina ceramic plungers are the heart of precise fluid control systems. They move liquids accurately. They resist deterioration from aggressive chemicals like acids and bases. This is important for chemical processing, water therapy, and pharmaceutical dosing. The ceramic does not respond with the liquids. This maintains the liquids pure. The plungers stay smooth and leak-free for a very long time. This conserves cash on substitutes and maintenance.

Ceramic tubes, rods, and cutting/welding components are one more crucial area. These elements face extreme warmth and physical tension. Alumina ceramic tubes direct cables and lasers accurately. Ceramic rods provide strong, non-conductive supports in high-voltage or high-temperature configurations. Fixtures made from this ceramic hold components securely during reducing or welding. They endure triggers and warm without melting or degrading. This makes sure exact, repeatable production results. They are stable and long lasting under thermal shock.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding

Here are 5 common questions about our China-made 99% Alumina Ceramic components for pumps and industrial use:

1. Why use alumina ceramic for these parts?

Alumina ceramic offers extreme hardness. It resists wear incredibly well. Parts last much longer than metal alternatives. It handles harsh chemicals easily. Corrosion is not a problem. This material keeps things reliable.

2. Can it handle tough conditions?

Yes. These ceramic parts excel in difficult environments. They withstand very high temperatures. They resist most strong acids and alkalis. Performance stays consistent. Downtime reduces significantly.

3. What’s the benefit of the smooth surface?

The surface finish is extremely smooth. Fluids flow past with minimal friction. Buildup or sticking is less likely. This is crucial for precise dosing pumps. Accurate fluid control happens. Contamination risks lower.

4. Is the ceramic strong enough?

Absolutely. The 99% purity alumina is very strong. It provides excellent mechanical strength. These parts handle significant pressure loads. They are dimensionally stable. Remember, ceramic is hard but brittle. Avoid sharp impacts during handling.

5. How do I clean these ceramic parts?

Cleaning is straightforward. The material’s chemical resistance helps. You can use strong cleaning agents safely. Common industrial cleaners work fine. Abrasive cleaning methods are usually unnecessary. Gentle wiping often suffices.

(China s’ 99% Alumina Ceramic Shaft Screw Alumina Ceramic Plunger Valve Dosing Pump Ceramic Tube Rod Cutting/Welding)

REQUEST A QUOTE

RELATED PRODUCTS

High Pressure Insulation Spare Part 99.5% Alumina Ceramic Piston Plunger Zirconia Ceramic Tube

Custom Alumina Ceramic Piston Pump & Plunger Bushing OEM CNC Machining Customized Ceramic Non-standard Processing

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

99% Alumina Ceramic Piston Polished Alumina Al2o3 Ceramic Plunger Pump Seramik Piston

Polished Wearable Pump Industrial Alumina Ceramic Shaft Plunger Piston