Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

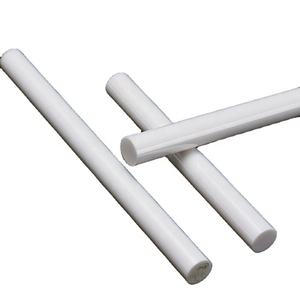

Overview of Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube

Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube)

Specifications of Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube

These custom ceramic parts start as high-purity 99% alumina zirconia. This mix develops a strong material perfect for demanding work. We make bars, bettors, poles, and tubes exactly to your dimensions. You tell us the dimension you need. We produce it specifically.

The material supplies excellent solidity. It stands up to wear extremely well. This implies parts last much longer under challenging conditions. It manages heats conveniently. Components stay steady also when points get hot. This ceramic is an excellent electric insulator. It will not perform electrical energy.

Machinability is a crucial function. You can equipment this ceramic after firing. This permits limited tolerances and complex shapes. It’s less complicated than working with lots of other ceramics. You obtain exact last parts without too much effort. Surface coatings can be fine-tuned. We offer options like as-fired, ground, or brightened. Pick what fits your application best.

Chemical resistance is very high. The material stands up to acids and bases. It won’t rust easily in extreme atmospheres. This makes it ideal for chemical handling equipment. Believe pump plungers, valve components, lab devices. Its stamina supports heavy lots accurately. These components will not bend or deform under pressure.

Applications consist of commercial equipment, medical tools, scientific instruments. Utilize it where metals stop working or break as well quick. It offers a trusted, lasting solution. Customized dimensions mean excellent suitable for your task. No requirement to adapt your style to standard supply. Obtain the precise ceramic component you require.

(Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube)

Applications of Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube

Personalized size high purity 99% alumina zirconia machinable ceramic bars, bettors, poles, and tubes fix challenging issues. They are exceptionally strong and wear-resistant. This makes them last a lot longer than metal or plastic parts. These ceramics deal with severe warmth extremely well. They maintain functioning reliably in high temperature environments.

These ceramic components resist chemical strike efficiently. Acids, bases, and solvents do not damage them conveniently. This is crucial for chemical processing tools. The material also handles abrupt temperature adjustments without fracturing. Thermal shock resistance is essential for numerous industrial uses.

The machinability is a significant advantage. You can shape this ceramic exactly using standard carbide tools. This permits intricate custom styles. It reduces production time and cost. You obtain components made specifically to your specifications.

High purity alumina zirconia bettors are necessary in pumps and valves. They provide a super-hard, leak-free sealing surface area. They function well in gas injection systems and HPLC pumps. Their reduced rubbing decreases wear on breeding components.

Ceramic rods and tubes see heavy use as overviews, shafts, and insulators. Their dimensional security is excellent. They don’t warp or change size with temperature level changes. Electric insulation residential or commercial properties are superior. These porcelains are perfect for high-voltage or electronic applications.

Bars made from this product serve as strong architectural parts. They support tons in harsh conditions. Heating system furnishings, kiln components, and warmth therapy fixtures benefit. The product stands up to rough particles and corrosive gases.

Scientists make use of these porcelains extensively in labs. Crucibles, example holders, and response tubes need pureness and resistance. The material does not pollute delicate experiments. Medical gadget manufacturers value its biocompatibility and toughness. It benefits medical devices and implants.

These porcelains offer unique benefits for demanding jobs. You require components that will not wear out, melt, or corrode. Custom dimensions fit your particular machine or assembly flawlessly. The mix of machinability and efficiency is tough to match. Industries rely upon them for critical elements each day.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube

Here are 5 common questions about our Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars, Plungers, Rods, and Tubes:

Can I get these ceramic parts made exactly to my size?

Yes. We specialize in custom sizes. Tell us the exact dimensions you need for your bars, plungers, rods, or tubes. We make them precisely to your specifications.

What makes this alumina zirconia ceramic special?

It’s very pure, 99% alumina. Adding zirconia makes it much stronger and tougher than regular alumina. This combination handles high stress much better. It resists wear extremely well. It also handles very high temperatures without changing.

Is it really easy to machine?

Yes. That’s a key benefit. Unlike many other advanced ceramics, this material can be machined using standard carbide tools. This allows for precise shaping, drilling, and finishing after the initial forming. You get complex parts without needing expensive diamond grinding only.

How does it perform in tough conditions?

It performs excellently. Its high strength and toughness mean it won’t break easily under load. It resists corrosion from chemicals. It maintains its properties at temperatures over 1500°C. It’s also an excellent electrical insulator. These properties make it reliable in demanding environments.

Where are these parts typically used?

They are used in many industries needing durable, high-performance components. Common uses include seals and bearings in pumps and valves. They work well as wear-resistant liners. They are ideal for insulating components in furnaces and electrical systems. They serve as precise plungers in metering devices. Any application needing a hard, non-corrosive, heat-resistant insulator benefits.

(Custom Size High Purity 99% Alumina Zirconia Machinable Ceramic Bars Plungers Ceramic Rod Tube)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Plunger Magnetic Pump Zirconia Ceramic Plunger

Fine Polishing Mirror Alumina Zirconia Ceramic Plunger Macor Rod

99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

Ignition Electrodes Spark Plug Alumina Ceramic Plunger For Ceramic Bush

High Pressure High Toughness Alumina Ceramic Plunger Pump Plunger Shaft