Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

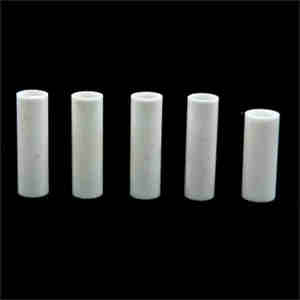

Overview of High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater

High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater)

Specifications of High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater

Right here are the specifications for the High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heating Unit. This part is made for demanding work. It uses zirconia-reinforced alumina ceramic. This material is very tough. It resists wear incredibly well. The surface area gets a high polish coating. This finish is smooth. It reduces rubbing substantially. That assists parts slide quickly.

The rod deals with very high temperatures. It works great above 1000 ° C. Thermal shock resistance is exceptional. Unexpected temperature changes won’t fracture it. Electrical insulation properties are excellent. This prevents existing leakage. It’s risk-free for electric heating applications. Chemical resistance is strong as well. Acids and antacid create little damage. This makes it good for rough chemical settings.

Precision grinding guarantees exact measurements. Tolerances are limited. This assures an excellent fit each time. The rod is very difficult. Firmness surpasses standard alumina. It lasts longer under heavy usage. High compressive toughness is crucial. It manages large pressure loads without breaking. Surface area level of smoothness is crucial. The brightened coating lessens particle buildup. Tidiness is much easier to maintain.

The bettor rod heating system is reputable. It supplies constant efficiency. Heat transfer is effective. This gives steady operating temperatures. Mechanical security is excellent. The rod won’t flex or warp easily. Its shape remains true. This part is built for tough problems. It functions fantastic under stress. Long life span is expected. Upkeep demands are low. That saves money and time.

(High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater)

Applications of High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater

High Polish Accuracy Zirconia Alumina Porcelain Plunger Pole Heaters take on difficult heating jobs. They function dependably where other products fail. These rods handle severe warm conveniently. They resist temperature levels far beyond what standard heaters can manage. Unexpected temperature changes don’t split them. This thermal stability is important.

Chemical resistance is one more significant benefit. Severe acids and bases cause no damages. Corrosive gases will not eat away at the surface area. This makes them ideal for chemical processing. They function securely in aggressive environments. Steel parts would rust quickly below.

Electric insulation is vital. These rods do not carry out electrical energy. They stop hazardous short circuits. This safety and security is essential around conductive materials. Operators stay protected.

The high gloss surface area matters. It minimizes friction. Relocating parts slide efficiently. Deterioration is greatly minimized. Tools lasts longer. Maintenance requires decline. The surface remains glossy also under heavy loads. This prevents sticking and binding.

These rods master demanding applications. Metal handling utilizes them constantly. Foundries depend on them for molten metal handling. They withstand intense heat near furnaces. Semiconductor making requirements ultra-clean, reliable heating. These rods deliver. Chemical plants utilize them for pumping and metering harsh fluids. They withstand assault perfectly. Laboratory tools commonly integrates them. Precision heating is vital for delicate tests. Food handling tools utilizes them also. They meet strict health criteria. Their smooth surface area prevents contamination.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater

What is a High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater?

It’s a special heating element. It heats liquids inside injection molding machines. The core is made from zirconia alumina ceramic. This material gets very hot. It transfers heat efficiently to the liquid flowing around it.

Why use Zirconia Alumina Ceramic?

This ceramic is very tough. It resists corrosion well. Harsh chemicals won’t damage it easily. It also handles extreme heat without cracking. This makes it reliable for constant high-temperature use. Its smooth surface prevents material sticking.

How long does this heater last?

It lasts a long time. The tough ceramic core doesn’t wear out fast. It handles thermal shock well. Sudden temperature changes won’t break it. This means less downtime for replacements. You get more consistent production over time.

Is installation difficult?

Installation is straightforward. It fits standard plunger rod assemblies. You need the correct size and power rating. Follow the manufacturer’s mounting instructions carefully. Ensure good electrical connections. Proper installation prevents problems later.

Is it safe for high temperatures?

Yes, it’s designed for high heat. The ceramic material stays stable under intense conditions. The high polish finish helps. It reduces friction and prevents material degradation. This maintains process safety and product quality. Regular checks are still smart practice.

(High Polish Precision Zirconia Alumina Ceramic Plunger Rod Heater)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Cylinder Liner 99 Alumina Plunger for Mud Pump

Custom High Polished 99% Alumina Machinable Ceramic Bars Plungers Rod

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Corrosion Resistance Insulating Al2O3 Alumina Ceramic Plunger Shaft Ceramic Rod

Alumina Ceramic Piston Ring High Pressure Pump Use Al2O3 Ceramic Plunger