Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

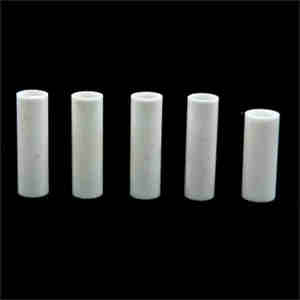

Overview of High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining)

Specifications of High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Below are the specifications for our high accuracy ceramic piston pumps. We utilize 95% and 99% pure alumina ceramic. This product is exceptionally hard. It withstands wear far better than steel. Your pump lasts much longer. It manages laborious. It will not wear quickly.

The core parts are the piston and plunger bushing. These are made from this unique ceramic. Accuracy CNC machining makes them completely smooth. Smooth surfaces reduce friction. Less friction suggests much less warm. Much less warmth means much less wear. Your pump runs cooler. It runs a lot more effectively. You save energy.

We offer personalized processing. Required a details size? We make it. Need an one-of-a-kind form? We machine it. Your stress washer has exact needs. Our pumps meet them. We construct parts for your machine. Not generic parts.

The high purity alumina ceramic resists chemicals. Extreme detergents will not harm it. Abrasives in water cause much less harm. Your pump remains dependable. It does regularly. Stress remains high. Flow remains constant.

These ceramic components handle high pressure. They manage heats. They work in demanding stress washer applications. Industrial cleansing requires robust pumps. Our ceramic pumps deliver. They are built challenging. They are constructed to last.

You obtain a precision part. You obtain a durable service. You get custom-engineered performance. This is vital equipment for significant cleaning power.

(High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining)

Applications of High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

These high precision ceramic piston pump components address challenging troubles. Criterion metal components wear out fast. They wear away quickly as well. Our 95% to 99% alumina ceramic pistons and bettor bushings transform that. This difficult ceramic material stands up to abrasion very well. Parts last much longer. Downtime reduces considerably. Maintenance costs go down.

These ceramic components deal with tough chemicals without damage. They stand up to solid acids and bases. This is vital for stress washing machines making use of severe cleansing services. The pump seals stay dependable. Leaks are prevented. Efficiency remains consistent. Equipment life prolongs.

Custom-made processing is essential. We maker these ceramic pistons and bushings specifically for your specific pump design. CNC machining achieves exact forms and tight resistances. Every part fits perfectly. This guarantees smooth pump operation. Stress output stays stable. Efficiency is optimized.

Pressure washing machines profit widely. Users see more powerful water jets. Cleaning power boosts. The pump sustains continuous high stress cycles. Dependability improves substantially. Operators trust fund the equipment more.

The advantages get to past pressure washing machines. Any application requiring long lasting, corrosion-resistant pump components obtains worth. Production processes use them. Water therapy plants rely upon them. Automotive screening needs them. Food and drink manufacturing applies them. These ceramic components deal with demanding atmospheres where metals stop working. They offer a smarter remedy for critical fluid handling.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Here are the top questions people ask about our high precision 95-99% alumina ceramic piston pumps and plunger bushings:

People want to know what makes this ceramic special. We use top-grade 95% or 99% pure alumina ceramic. This material is extremely hard. It resists wear incredibly well. It handles chemicals without corroding. It endures high temperatures easily. This toughness means parts last much longer than metal. Downtime gets reduced significantly.

Everyone asks about precision. We achieve very tight tolerances. Our CNC machining guarantees exact dimensions every time. This precision fit is critical. It creates a perfect seal inside your pressure washer pump. Leaks get prevented. Pump efficiency stays high. Consistent high pressure happens.

Customization matters a lot. We make parts for many different pump models. Need a specific size? We do it. Need a unique shape? We do it. Need special surface finishes? We do it. Send us your drawings or samples. We create the exact ceramic plunger or bushing you require.

Pressure handling is a key concern. These ceramic parts excel under high pressure. Alumina ceramic has immense compressive strength. It won’t deform or crack. Your pump maintains peak performance reliably. Heavy-duty cleaning jobs get handled easily.

People worry about the machining process. We specialize in precise ceramic machining. Working with this hard material demands expert skills. We possess the right CNC technology. We know the correct techniques. We avoid cracks or chips. You receive perfectly finished, ready-to-install components. Quality is guaranteed.

(High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining)

REQUEST A QUOTE

RELATED PRODUCTS

High Polished Outer Diameter Wearable 99% Alumina Ceramic Plunger bar Rod

High Pressure High Toughness Alumina Ceramic Piston Plunger Shaft Piston Keramik for Pump

High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve

High Pressure Alumina Ceramic Plunger Rod Al2O3 Ceramic Tube

High Temperature Thermocouple Alumina Ceramic Tube for Plunger Protection