Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

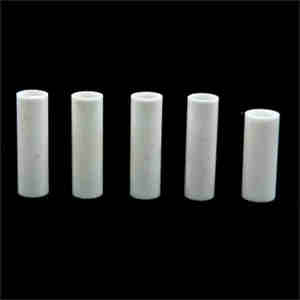

Overview of High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve

High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve)

Specifications of High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve

This high precision Al2O3 alumina ceramic piston plunger is for demanding pump and valve applications. It also serves completely as a ceramic sleeve. The material is over 95% aluminum oxide. This alumina ceramic deals superior solidity. It ranks extremely high on the Mohs range. This extreme solidity straight converts to excellent wear resistance. The bettor surface area stays smooth much longer than steel alternatives. Rubbing is substantially reduced throughout operation.

Deterioration is not a trouble. Alumina ceramic is chemically inert. It stands up to exposure to several aggressive chemicals, acids, and alkalis. Corrosion is difficult. This makes it ideal for severe chemical processing environments. The product likewise has high compressive stamina. It manages hefty lots and pressures dependably. Thermal stability is an additional vital benefit. The plunger does regularly from very low to very high temperatures. It resists thermal shock well.

Electrical insulation is inherent. Alumina ceramic does not carry out electrical energy. This avoids stray currents and electrolytic deterioration. The surface area coating is extremely smooth. Accuracy grinding attains tight dimensional tolerances. This reduces fluid leak and ensures efficient pump operation. The plunger keeps its specific form with time. Dimensional stability is superb.

These buildings combine to supply long service life. The plunger withstands abrasive wear and chemical attack. Upkeep intervals expand. Pump efficiency remains high. Downtime lowers. The ceramic plunger is a cost-efficient remedy for crucial applications. It works reliably in tough problems.

(High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve)

Applications of High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve

Al2O3 alumina ceramic piston bettors are important parts in demanding pump and valve systems. These bettors offer substantial benefits over typical metal parts. Alumina ceramic is incredibly hard. It stands up to wear much better than steel or other steels. This firmness means the plunger surface area remains smooth much longer. A smooth surface area is essential for preserving tight seals inside pumps and shutoffs.

Rubbing creates significant problems in pumps. Alumina ceramic bettors substantially lower rubbing. Much less rubbing implies much less energy is required to run the pump. Power financial savings accumulate rapidly in time. Lowered rubbing also indicates much less warmth develops inside the pump. Cooler operation protects other pump parts. It prolongs the general life of the whole system.

Chemical resistance is one more essential advantage. Alumina ceramic handles hostile fluids well. Acids, antacid, solvents, and various other extreme chemicals won’t harm the ceramic surface. Steel components often wear away or break down in these environments. Ceramic bettors avoid this problem. They guarantee dependable efficiency pumping difficult chemicals. This dependability is essential in chemical handling, water treatment, and pharmaceutical applications.

These plungers function completely as ceramic sleeves as well. The sleeve overviews the bettor rod exactly. Ceramic’s dimensional security is outstanding. It doesn’t swell or reduce with temperature modifications like some metals. This stability maintains clearances consistent. Constant clearances stop leakages and preserve effectiveness. Precision is essential for high-pressure pumps and metering systems.

Resilience converts straight to cost financial savings. Alumina ceramic plungers last sometimes longer than steel choices. Tools runs longer between upkeep quits. Downtime expenses reduce substantially. Substitute part costs decrease over the pump’s life time. The initial financial investment pays back quickly. Dependability boosts general plant performance. Operators count on these elements in vital procedures.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve

What material is the piston plunger?

It is made from high-purity alumina ceramic (Al2O3). This material is very hard. It is also chemically inert. These properties are essential for demanding pump applications.

Why is high precision important?

Tight dimensional accuracy is critical. The plunger must fit perfectly inside the ceramic sleeve. A precise fit minimizes fluid leakage. It ensures consistent pump performance. It reduces unwanted wear on both parts.

How does it resist wear?

Alumina ceramic is extremely hard. Hardness directly fights abrasion. The material does not corrode. It handles abrasive fluids well. This combination gives a long service life. It reduces downtime for replacements.

Can it handle high temperatures?

Yes. Alumina ceramic withstands very high heat. It performs reliably in hot environments. This is important for pumps moving heated fluids. The material keeps its strength and shape.

What pumps use these plungers?

They suit many high-performance pump types. Examples include chemical dosing pumps, high-pressure pumps, and slurry pumps. They are ideal anywhere extreme wear resistance and chemical stability are needed.

(High Precision Al2o3 Alumina Ceramic Piston Plunger for Pump Valve Ceramic Sleeve)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Zirconia/Alumina Ceramic Plunger For Pumps

Mirror Polished Alumina Ceramic Plunger Porcelain Insulators 99 for Promotion

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Supply Wear-resitance 99 Alumina Al2o3 Ceramic Plunger/rod/pillar Customized

Industrial Ceramic Alumina Zirconia Plunger Parts Electrical Ceramic Insulator Plates Moulding Processing Service