Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

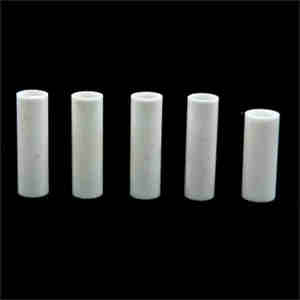

Overview of High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve

High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve)

Specifications of High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve

These high accuracy molding porcelains are produced challenging medical tasks. Alumina ceramic and zirconia ceramic are the primary materials. They are very hard. They withstand put on very well. This matters for parts like piston bettors and sleeves. These parts deal with continuous friction. They need to last a long time. Our ceramics manage this quickly.

The manufacturing makes use of high accuracy molding. This method creates parts with specific sizes and shapes. Tight tolerances are vital. Medical tools require ideal fit. Precision molding ensures this. It also makes surface areas really smooth. Smooth surfaces are polished after molding. This ultra-smooth finish is key. It reduces rubbing inside pumps and shutoffs. Fluid streams efficiently. Particles are much less most likely to stick. This keeps things tidy and trustworthy.

Alumina ceramic deals fantastic firmness and price performance. It stands up to chemical strike well. Zirconia ceramic is even tougher mechanically. It has premium crack durability. Both products are biocompatible. They are safe inside the human body. They endure duplicated sterilization cycles. Cleaning techniques like autoclaving are no worry. The porcelains will not break down or corrode.

These plungers and sleeves work in requiring clinical equipment. Assume infusion pumps, dialysis machines, laboratory analyzers. They handle exact fluid application. Integrity is non-negotiable. Our ceramic parts provide that. They maintain precision over countless cycles. Failure means machine downtime. Downtime costs cash and dangers client treatment. Our components lower this danger dramatically. They surpass metals and plastics in wear applications. They save money in time. Substitute occurs less usually. Makers run smoother longer.

(High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve)

Applications of High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve

High precision molding ceramics supply leading efficiency in demanding medical setups. Alumina and zirconia porcelains are crucial materials below. These ceramics use phenomenal solidity. This firmness directly translates to exceptional wear resistance. Components maintain their smooth surfaces much longer. This lowers friction dramatically. Less friction means much less bit generation. Sanitation is crucial for medical devices. These ceramics are likewise extremely polished. The smooth surface lessens sticking. Fluids move conveniently past the surfaces. This is essential for consistent tool procedure.

Clinical piston bettors and sleeves deal with continuous stress. They sustain repeated movement and liquid stress. Standard materials can wear down promptly. Ceramic bettors and sleeves handle this far better. Their extreme wear resistance extends service life substantially. Devices function reliably for longer periods. This lowers downtime for upkeep. It additionally cuts replacement expenses gradually.

Precision is non-negotiable in medical elements. High accuracy molding guarantees exact measurements. Every piston plunger and sleeve fits flawlessly. Limited tolerances are consistently accomplished. This precision warranties trustworthy sealing. It stops leakages efficiently. Regular efficiency is preserved set after set. Medical procedures rely on this accuracy.

Zirconia ceramic includes extra strength. It resists splitting under effect far better than some ceramics. Alumina gives outstanding chemical stability. It stands up to rough cleaning agents and bodily liquids without degrading. Both products are biocompatible. They satisfy rigorous safety and security requirements for clinical implants and devices. This makes them secure for patient call.

The mix of precision, wear resistance, and biocompatibility is powerful. Clinical ceramic piston bettors and sleeves run smoothly. They last much longer under demanding conditions. They help guarantee device dependability and person safety. These porcelains are a clever selection for vital medical fluid handling.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve

What makes these ceramic pistons so long lasting?

The material resists wear extremely well. Alumina ceramic handles friction better than metal. This means less wear over time. Parts last longer in demanding medical devices.

Why is the surface so smooth?

We polish the ceramic to a very high finish. A smooth surface reduces friction inside sleeves. Smooth movement is critical for precision medical equipment. Less friction also means less wear.

How hot can these ceramic pistons get?

They handle high temperatures well. Alumina ceramic stays strong and stable even under heat. This is vital for devices needing sterilization or generating heat during use. Performance doesn’t drop.

Is this ceramic safe for medical use?

Yes, absolutely. Alumina ceramic is biocompatible. It meets strict safety standards for medical devices. It won’t react with bodily fluids or tissues. Safety is guaranteed.

How do I clean these ceramic pistons?

Cleaning is straightforward. Use standard hospital-grade disinfectants. Avoid very harsh chemicals or abrasive cleaners. Gentle cleaning maintains the smooth surface. Follow your device maker’s specific cleaning instructions.

(High Precision Molding Ceramics High Wear Resistance Polish Alumina Ceramic Zirconia Piston Plunger For Medical Ceramic Sleeve)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistant Alumina Ceramic Plunger Pressure Pump Spare Parts Support Customize

Ceramic Plunger for Lithium Battery Injection Pump Precision Ceramic Piston Canned Pump Alumina

Customized High Precision Alumina Plunger Assembly

High Compressive Strength Alumina Industrial Ceramic Shaft Parts Ceramic Plunger Piston with Services Welding Cutting Bending

99 High Purity Alumina Ceramic Piston Plunger for Valve