Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

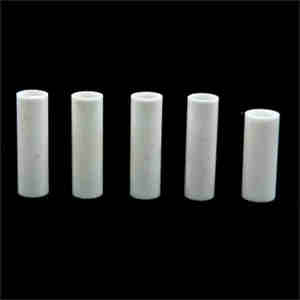

Overview of High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger

High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger)

Specifications of High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger

High stress pumps encounter challenging conditions. Alumina ceramic pistons handle these needs well. They are made from Al2O3 ceramic. This product is extremely tough. It stands up to wear very successfully. This leads to a much longer service life contrasted to steel parts. The piston surface area stays smooth much longer. Rubbing lowers significantly. Power intake drops.

The ceramic stands up to chemical attack. Acids, alkalis, and solvents create little damage. This chemical inertness is important. It protects against corrosion and product deterioration. Pump performance stays secure. Contamination risks decrease. The ceramic likewise manages heats well. It doesn’t broaden a lot under heat. Dimensional security is outstanding. Securing remains dependable. Thermal shock resistance is excellent. Sudden temperature level adjustments cause much less fracturing threat.

Alumina ceramic is electrically shielding. Electrical problems are stayed clear of. The material is non-magnetic. Magnetic interference isn’t an issue. Surface coating is important. Our pistons accomplish Ra ≤ 0.1 μm surface roughness. This ultra-smooth finish lessens seal wear. Leak is prevented. Liquid flow effectiveness improves. Dimensional precision is rigorous. We hold limited tolerances. Common size resistance is within ± 0.002 mm. This makes sure a perfect fit. Consistent performance is guaranteed.

These pistons operate in numerous requiring locations. Waterjet reducing intensifier pumps utilize them. High stress cleansing equipment depends on them. Descaling systems require their toughness. Chemical handling pumps profit significantly. Oil and gas applications discover them necessary. They are a direct substitute for steel plungers. Installation is simple. Downtime is reduced. Upkeep costs drop significantly. Pump dependability boosts. The alumina ceramic piston is a wise upgrade. It addresses typical wear problems. It delivers lasting performance.

(High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger)

Applications of High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger

High stress pumps demand tough parts. Alumina ceramic pistons (Al2O3 ceramic plungers) deliver this sturdiness. They are made from really hard aluminum oxide ceramic. This material holds up against severe conditions flawlessly. Its hardness rivals solidified steel. This means the piston surface resists wear extremely well. Pumps last much longer before needing service. Downtime reduces considerably. Maintenance expenses go down also.

Chemical resistance is an additional significant advantage. Alumina ceramic shrugs off strong acids, strong alkalis, and solvents. This is essential popular sectors. Chemical handling plants rely upon these pistons. Water treatment systems utilize them extensively. Petrochemical applications benefit considerably. The piston stays intact despite hostile liquids. Pump dependability boosts drastically.

Warm doesn’t trouble alumina ceramic either. It manages heats without deforming. Performance stays secure under thermal stress. This is critical for processes producing warm. Oil drilling devices uses these bettors. High-pressure cleansing systems rely on them. Heat management comes to be less complicated.

Surface area smoothness matters a whole lot. Alumina ceramic pistons have an extremely fine surface. Rubbing versus seals and cylinders reduces. Much less rubbing indicates much less energy lost. Pumps run much more successfully. Warmth generation from rubbing likewise decreases. Seal life often boosts. Operational smoothness boosts.

These homes make Al2O3 pistons suitable for critical work. They operate in hydraulic intensifiers producing tremendous force. Metering pumps require their precise application ability. Descaling systems in steel mills utilize them. High-pressure waterjet reducing depends on their resilience. The ceramic deals with consistent stress cycles without fatigue. Leak risks are decreased.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger

Why choose alumina ceramic pistons over metal ones? Ceramics handle high pressure extremely well. They are much harder than steel. This hardness means they resist wear far better. Your pump seals last longer. Ceramics also resist chemical attack. Harsh fluids won’t damage them like they damage metal. This reduces corrosion problems.

How do these ceramic plungers manage such high pressure? Alumina ceramic is very strong under compression. It doesn’t bend or deform easily. The material stays rigid even under intense force. This keeps the pump chamber sealed tightly. Pressure stays consistent. Leaks are minimized. Performance stays reliable.

Will the ceramic piston last a long time? Yes, its wear resistance is excellent. Alumina ceramic is nearly as hard as diamond. Abrasive particles in the fluid cause less damage. The piston surface stays smooth much longer. This extends the life of the piston itself. It also protects the mating seal surfaces. You get longer service intervals.

Can these plungers handle hot fluids? Alumina ceramic performs well at high temperatures. It keeps its strength when things get hot. Metal parts can soften or weaken. Ceramic stays stable. This is good for hot water cleaning or steam applications. Thermal shock resistance is also good. Sudden temperature changes are less likely to crack it.

What maintenance does the ceramic plunger need? Maintenance focuses mainly on the seals. Inspect seals regularly. Replace them when worn. Keep the plunger surface clean. Check for any chips or cracks during seal changes. A damaged plunger needs replacement. Handle ceramic parts carefully. Avoid impacts during installation. Proper installation prevents damage.

(High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger)

REQUEST A QUOTE

RELATED PRODUCTS

99 Wear Resistant Alumina Ceramic Plunger Al2O3 Ceramic Bush Ceramic Tube

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining

Customized 99% Alumina Ceramic Plunger Al2O3 Pump Small Doses Alumina Ceramic Rotary Valve Piston Pump

Ceramic Wear and Corrosion Resistant Al2o3 Alumina Ceramic Piston Plunger Bushing Rod for High Pressure Pump

Fine Polishing Mirror Alumina Zirconia Ceramic Plunger Macor Rod