Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

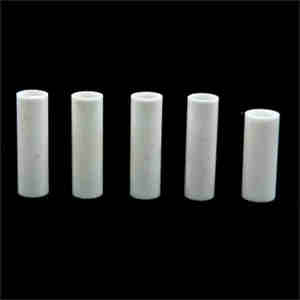

Overview of High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve

High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve)

Specifications of High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve

This alumina ceramic pump plunger sleeve makes use of high pureness 99% Al ₂ O TWO. It uses excellent efficiency for demanding pumping applications. The product is exceptionally difficult. It determines around 1500 HV. This firmness directly combats wear. Elements last a lot longer. You save cash on substitutes. Downtime lowers considerably.

Chemical resistance is a major strength. The alumina ceramic deals with solid acids and bases well. It stands up to deterioration from several hostile chemicals. This makes it safe for extreme chemical handling. It functions reliably where steels fall short. You prevent leaks and contamination.

High temperature stability is an additional key attribute. It withstands temperature levels approximately 1600 ° C. Efficiency remains consistent under extreme warm. Thermal shock resistance is good. The sleeve won’t fracture easily with sudden temperature level adjustments. This is essential for processes entailing warmth cycling.

Electrical insulation properties are inherent to alumina. It protects against electrical currents from going through. This includes safety and security in electrically sensitive settings. The product is also extremely tight. It has high compressive stamina. This dimensional security is important for precise pumping activity. It keeps resistances tight over time.

Surface area coating alternatives are available. Smooth surfaces reduce rubbing. This lowers endure mating parts. Fluid flow remains effective. You get consistent pump efficiency. The bettor sleeve fits different pump types. It fits chemical handling, water treatment, and oil & gas applications. It deals with unpleasant slurries successfully. This alumina ceramic bettor sleeve is a reputable option for difficult pumping work.

(High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve)

Applications of High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve

High pureness alumina ceramic components resolve difficult problems in pumps. Metal parts usually fail in severe conditions. They break quickly. They rust or corrode. This causes failures and costly stops. Our 99% alumina (light weight aluminum oxide) bettors, tubes, and sleeves handle this much better.

This sophisticated ceramic is very difficult. It resists abrasion far better than steel. Sand, grit, or slurry in liquids rapidly damage metal. Alumina components last much longer. This lowers just how commonly you require to change components. It cuts downtime costs considerably.

Chemical assault ruins steel parts quickly. Acids, bases, and solvents trigger rust. High pureness alumina withstands nearly all chemicals. It stays steady and solid. This makes it best for chemical processing pumps. It takes care of acids safely. It functions well in hostile chemical environments.

Water therapy plants encounter rough and harsh water. Dirty water uses down metal plungers and sleeves. Alumina components endure this continuous wear. They maintain pumps running dependably much longer. They need less maintenance with time.

High pureness alumina is likewise non-porous. It protects against liquid absorption. It prevents contamination. This is essential for pure liquids in drugs or food. It keeps fluids clean. It meets stringent health criteria.

The smooth surface area coating of alumina reduces friction. This reduces wear on seals and mating parts. It improves pump effectiveness. It assists the entire pump last longer. Less friction suggests less energy used as well.

These alumina plungers, tubes, and sleeves fit lots of pump kinds. They operate in plunger pumps, piston pumps, and metering pumps. They offer a reliable upgrade over steel components. They supply longer life. They reduce upkeep costs. They boost pump efficiency in laborious.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve

What is a high purity alumina ceramic pump plunger tube?

It’s a tough sleeve made from nearly pure aluminum oxide ceramic. This sleeve fits inside pumps. It protects the pump’s moving plunger rod from damage. Think of it as armor for the plunger.

Why use 99% alumina ceramic for this?

Alumina ceramic is incredibly hard. It resists wear far better than metal. It also handles harsh chemicals without corroding. High purity means fewer impurities. This makes the ceramic even stronger and more reliable under pressure. It lasts much longer than metal parts.

What are the main benefits over metal sleeves?

Metal sleeves wear out fast from friction and chemicals. This ceramic sleeve lasts much longer. It reduces pump downtime for repairs. It saves money over time. It keeps the pump running smoothly longer. It works well in tough conditions like chemical processing.

Where are these ceramic sleeves typically used?

They go into pumps moving difficult liquids. Examples include chemical dosing pumps, water treatment pumps, oil and gas metering pumps, and slurry pumps. Any place needing extreme wear resistance and chemical protection uses them. They handle abrasive or corrosive fluids metal cannot.

Are there special handling needs?

Yes. Alumina ceramic is hard but can be brittle. Avoid sharp impacts during installation. Ensure the plunger rod fits correctly inside the sleeve. Use proper installation tools. Follow the pump manufacturer’s guidelines. Correct installation prevents cracking.

(High Purity 99% Alumina Aluminium Oxide Advanced Ceramic Pump Plunger Tube Pipe Sleeve)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision Wear Coorosion Resistant Ceramic Plunger Ceramic Pistons Alumina Ceramic

Ceramic Cartridge Precision Parts 99 Alumina Textile Industry Ceramic Plunger Textile Ceramic Accessories

99 High Purity Alumina Ceramic Piston Plunger for Valve

Innovacera 99.7% Polishing Alumina Ceramic Piston Plunger For High-Pressure Pumps/Valves

Custom Glaze Polish Ceramic Rod Wear Corrosion Resistant Alumina Ceramic Rod/shaft/plunger