Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

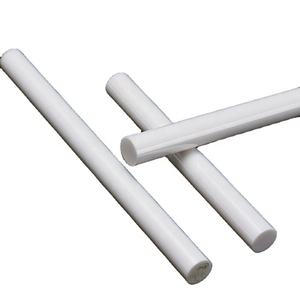

Overview of High Quality Custom Alumina Ceramic Plunger With Sleeve

High Quality Custom Alumina Ceramic Plunger With Sleeve is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of High Quality Custom Alumina Ceramic Plunger With Sleeve

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(High Quality Custom Alumina Ceramic Plunger With Sleeve)

Specifications of High Quality Custom Alumina Ceramic Plunger With Sleeve

Top quality customized alumina ceramic plungers with sleeves offer requiring commercial applications. These plungers make use of pure alumina ceramic material. Alumina supplies extraordinary hardness. Alumina resists wear extremely well. Alumina deals with high temperatures conveniently. Alumina stands up to strong chemicals accurately. Deterioration is not a problem for alumina. The bettor surface remains extremely smooth. This level of smoothness lessens friction. Rubbing reduction is important for long life.

The matching ceramic sleeve supplies exact alignment. The sleeve holds the bettor firmly. This tight fit protects against wobbling. Tottering reasons unequal wear. The sleeve likewise overviews the bettor properly. Exact guidance ensures regular operation. Regular procedure is vital for dependable performance.

Personalization is an essential function. Dimensions adapt to particular machinery requirements. Plunger diameters differ widely. Bettor sizes are tailored. Sleeve dimensions match the plunger specifically. Accurate fits are compulsory. Tolerance degrees are extremely limited. Typical resistances reach +/- 0.1 mm. Specific resistances depend upon the application. Complicated forms are feasible. Odd forms call for unique grinding. Surface area finishes are adjustable. Finer coatings decrease rubbing even more. Finer coatings set you back extra.

Product purity is always high. High purity alumina guarantees stability. Stability indicates constant performance. Constant performance occurs with time. Contaminations damage the ceramic. Weak porcelains fail early. Manufacturing uses sophisticated sintering. Sintering controls density carefully. High thickness stops fracturing. Cracking reasons plunger failing. Quality checks happen throughout manufacturing. Checks include dimensional confirmation. Checks confirm surface quality. Non-destructive testing finds hidden flaws. Every plunger and sleeve set is tested. Evaluating warranties fit and function.

(High Quality Custom Alumina Ceramic Plunger With Sleeve)

Applications of High Quality Custom Alumina Ceramic Plunger With Sleeve

Top quality custom-made alumina ceramic bettors with sleeves serve vital roles throughout markets. These parts excel in requiring fluid handling applications. Pumps depend on them for precise liquid control. Their smooth surfaces decrease friction during operation. This lowers wear significantly. Bettor and sleeve collections maintain tight seals under stress. Leakage prevention is crucial for reliable pumping.

Chemical processing makes use of these ceramic components extensively. Alumina ceramic withstands hostile acids and solvents. Metal alternatives typically wear away or deteriorate promptly right here. Ceramic bettors withstand chemical strike effectively. They make certain process reliability and security. Downtime reduces with their long service life.

Clinical tool makers choose these porcelains for analytical instruments. Constant efficiency matters greatly in diagnostics. Ceramic plungers deliver precise liquid volumes repetitively. Their biocompatibility suits medical applications. Contamination risks go down with inert ceramic products.

Industrial automation integrates these bettors right into high-cycle machinery. Alumina ceramic deals with intense mechanical stress. It stands up to abrasion from suspended bits in fluids. This durability cuts maintenance regularity. Production lines run much longer without disruption.

Semiconductor fabrication needs severe pureness. Customized ceramic plungers meet these strict requirements. They create marginal particulates. Accuracy activity is non-negotiable for chip manufacturing. These components deliver the required precision.

Oil and gas operations deploy them in rough downhole atmospheres. High pressure and rough fluids obstacle devices. Ceramic plungers withstand these problems better than metals. Their integrity supports continual extraction processes.

Food and beverage manufacturing uses alumina ceramic for hygienic factors. The material doesn’t harbor microorganisms. It endures regular cleansing cycles. Item stability stays secured. Constant application is achievable.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Custom Alumina Ceramic Plunger With Sleeve

High Quality Custom Alumina Ceramic Plunger With Sleeve FAQs

What makes your alumina ceramic plungers high quality?

We use top-grade alumina material. This material is super hard. It resists wear extremely well. Our strict manufacturing process ensures precise dimensions. Every plunger meets exact performance standards. Consistent quality is guaranteed.

Can you make custom sizes and shapes?

Yes, absolutely. Customization is our specialty. We make plungers and sleeves to fit your pump perfectly. Provide your specific dimensions. We handle complex shapes too. Your exact requirements are met.

Why use alumina ceramic instead of metal?

Alumina ceramic is much harder than metal. It lasts much longer under friction. The material doesn’t react with harsh chemicals. It handles acids and solvents safely. Corrosion isn’t a problem. You get reliable performance in tough conditions.

How long do these plungers typically last?

Lifespan depends heavily on the application. Proper installation matters. Correct operating conditions are crucial. Generally, alumina plungers last many times longer than metal ones. Expect significantly reduced downtime. Maintenance costs drop sharply.

Where are these plungers with sleeves used?

They fit demanding pump applications. Common uses include chemical processing equipment. Metering pumps need them. High-pressure liquid systems rely on them. Oil and gas applications benefit. Anywhere sealing and wear resistance are critical, they perform.

(High Quality Custom Alumina Ceramic Plunger With Sleeve)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina 99 Ceramic Mirror Tube Ceramic Plunger Pump Ceramic Shaft Sleeve Support Customization

99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

High Precision Pressure 95% 99% Ceramic Washers Piston Pump Alumina Ceramic Piston Plunger Bushing

95% 99% Polishing Solid Al2O3 Alumina Ceramic Plunger Shaft

China s Customized Alumina Ceramic Plunger Tube Piston Plunger Shaft