Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

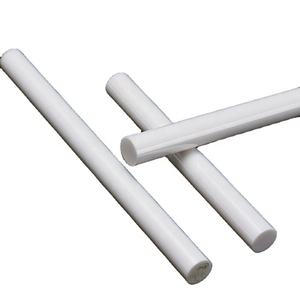

Overview of Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services)

Specifications of Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

These insulating alumina ceramic plungers work reliably in filling metering dosing pumps. The material choice matters. Alumina ceramic offers outstanding electrical insulation properties. This prevents unwanted current flow in sensitive pump applications. It provides strong resistance to chemical attack. Many harsh fluids won’t damage it. Wear resistance is another key benefit. The plunger maintains its shape and surface integrity over long periods. This reduces downtime and replacement costs.

High temperature stability is built-in. Alumina ceramic handles significant heat without warping or losing strength. This is crucial for demanding pumping environments. Precision machining is non-negotiable. Each plunger meets exact dimensional tolerances. Consistent performance relies on this accuracy. Surface finish is critical too. We achieve a very smooth finish. This minimizes friction and prevents premature seal wear. Leaks are less likely.

We supply these plungers as standalone components. They integrate seamlessly into existing pump systems. Custom sizes and configurations are possible. We understand specific pump designs have unique needs. Ask about tailoring dimensions to your exact specifications. We also offer related silicon nitride parts. Silicon nitride provides exceptional toughness. It withstands severe mechanical stress. This material suits extreme conditions.

Our capabilities extend beyond supply. We provide expert welding services for ceramic components. Precision cutting services are also available. We handle complex shapes and tight tolerances. We process both alumina and silicon nitride ceramics. Our machining expertise ensures high-quality results. You get components ready for immediate use in your pump assembly.

(Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services)

Applications of Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

Insulating alumina ceramic plungers are vital components in many tough industrial jobs. These plungers handle demanding conditions easily. They resist chemical attack effectively. They withstand severe wear over time. They manage high temperatures without trouble. This makes them perfect for filling, metering, and dosing pumps.

Pump systems need parts that last. Alumina ceramic plungers provide this reliability. They prevent leaks consistently. They ensure precise fluid control every time. This accuracy is critical for chemical processing. It matters in pharmaceutical manufacturing too. Food and beverage production relies on it heavily. Using these plungers cuts downtime significantly. It lowers maintenance costs noticeably. It boosts overall pump efficiency.

Silicon nitride parts often work alongside alumina ceramics. Silicon nitride offers extreme hardness. It provides excellent thermal shock resistance. Combining these materials creates superior solutions. This combination works well in high-stress pump applications. It performs reliably in aggressive environments.

Welding and cutting processes demand robust components. Insulating alumina ceramics serve well here. They act as durable nozzles and guides. They function effectively as insulating spacers. Their high electrical resistance is crucial. It isolates parts safely during high-energy tasks. This prevents dangerous electrical shorts. It protects sensitive equipment reliably. Plasma cutting benefits greatly. Laser welding systems see improved performance. Other thermal processing methods gain stability.

Precision machining services shape these ceramic parts. Experts grind alumina ceramics to exact specifications. They achieve the tight tolerances pumps require. This precision ensures smooth plunger operation. It guarantees a perfect seal within the pump bore. Consistent, leak-free performance depends on this accuracy. Properly machined plungers extend pump service life considerably. They deliver dependable results shift after shift.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services

Here are 5 FAQs about Insulating Alumina Ceramic Plungers for Metering Pumps:

What are these plungers used for? These plungers move fluids precisely in metering pumps. They handle corrosive liquids and high temperatures. Alumina ceramic provides excellent electrical insulation. This prevents stray currents damaging the pump or fluid.

Why pick alumina ceramic? Alumina ceramic resists wear exceptionally well. It lasts much longer than metal parts. It handles very high temperatures easily. It doesn’t react with most harsh chemicals. Its electrical insulation is crucial for safety and performance.

How hot can they get? Alumina ceramic plungers withstand extreme heat. They operate reliably over 1500°C. This makes them perfect for hot processes. Metal parts would fail much sooner.

Do they resist chemicals? Yes, alumina ceramic resists most acids and alkalis well. It handles aggressive solvents. This chemical inertness prevents corrosion and contamination. It keeps the fluid pure and the pump running longer.

Can I get custom sizes? Yes, custom sizes and shapes are available. We machine alumina ceramic precisely. This ensures a perfect fit for your pump. We offer small batches and large production runs. Get the exact plunger you need.

(Insulating Alumina Ceramic Plunger for Filling Metering Dosing Pump Silicon Nitride Parts Welding Cutting Processing Services)

REQUEST A QUOTE

RELATED PRODUCTS

99% Al2O3 Alumina Ceramic Tube Aluminium Oxide Ceramic Plunger Pipe Roller for Industrial Application Parts

High Pressure Pump Alumina Ceramic Piston Al2O3 Ceramic Plunger

75% Aluminum Oxide Ceramic Support Tube Alumina Plunger Plug In Stock

99% Al2O3 Alumina Ceramic Piston Plunger for Pumps Valve Ceramic Tubes

Alumina Ceramic Plunger High Pressure Cleaning Machine Pump Used Al2O3 Ceramic Plunger