Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

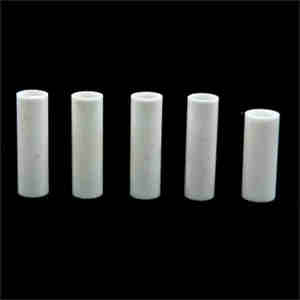

Overview of Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger

Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger)

Specifications of Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger

This alumina ceramic shaft piston bettor utilizes high-grade Al2O3 product. Its purity is exceptionally high. This suggests over 99.5% alumina web content. Pollutants are maintained really reduced. This high purity provides the component excellent residential or commercial properties. It becomes exceptionally hard. The hardness comes close to that of diamonds. This solidity directly deals with wear. The bettor resists abrasion extremely well. It lasts a lot longer than metal parts in abrasive problems. Wear rates are very little. This decreases downtime and replacement costs.

The material takes care of extreme warmth quickly. It works accurately at temperature levels over 1600 ° C. Thermal shock resistance is great. Sudden temperature level adjustments create less breaking threat. Rust is not an issue. Acids, antacid, and solvents have little impact. This makes the bettor ideal for rough chemical settings. Oxidation resistance is fundamental. The surface stays secure in oxidizing ambiences.

Surface area surface is extremely smooth. Precision grinding achieves this. A smooth surface area reduces friction significantly. It additionally stops product sticking and accumulation. Dimensional accuracy is tight. Resistances are held exactly. This ensures constant efficiency and fit. Electric insulation properties are excellent. The bettor does not conduct power. This is crucial in particular applications.

Compressive toughness is really high. The plunger withstands hefty lots without flawing. Flexural toughness is good too. It withstands damaging under bending pressures. These homes make it trusted under requiring mechanical stress. The thickness is modest. It supplies stamina without excessive weight.

This bettor is ideal for serious service. It functions well in pumps, shutoffs, and meters. It executes in chemical processing devices. It manages unpleasant slurries efficiently. It operates in high-temperature furnaces. It operates in demanding securing applications.

(Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger)

Applications of Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger

Refractory high purity alumina ceramic offers phenomenal performance for demanding applications. Its severe firmness resists wear efficiently. This property makes it perfect for shafts subjected to consistent friction. Alumina shafts maintain specific dimensions much longer than steel choices. They significantly lower equipment downtime. This saves significant upkeep expenses over time.

Pistons benefit considerably from this material. Alumina’s low friction coefficient reduces power loss during movement. It produces less warmth contrasted to steel pistons. High pureness alumina also stands up to hostile chemicals without wearing away. This reliability is vital in chemical pumps and hydraulic systems. Piston life extends drastically.

Plungers face severe problems in many pumps. Alumina ceramic plungers succeed right here. Their wear resistance protects against racking up and leakage. They handle high pressures dependably. Temperature level extremes cause very little concerns. Alumina stands up to thermal shock well. This security ensures consistent pump procedure. Plungers made from this ceramic last significantly longer.

The material’s electric insulation adds an additional benefit. Alumina elements won’t perform power. This security function is important in electric or digital applications. Its inert nature stops contamination. Food, drink, and pharmaceutical processes depend on this pureness. Alumina will not respond with items.

High pureness alumina ceramic withstands extreme warmth. It carries out accurately in high-temperature atmospheres. Heating system parts and thermal handling tools utilize it thoroughly. Its mix of hardness, chemical inertness, and thermal security is unequaled. Designers select Al2O3 for critical components requiring optimum longevity. Shafts, pistons, and bettors made from this ceramic deliver tried and tested results throughout industries like manufacturing, chemical processing, power, and clinical tools. They deal with laborious where various other products fall short rapidly.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger

What is this plunger used for?

It handles tough jobs in pumps and valves. It moves liquids or gases. It works in harsh conditions. High heat, strong chemicals, and heavy wear won’t damage it easily. It’s common in oil and gas, chemicals, and mining gear.

Why pick Alumina Ceramic over metal?

Alumina Ceramic is much harder than steel. It resists wear far better. This means parts last longer. It saves money on replacements and downtime. It won’t rust. Strong acids and bases don’t attack it. Metal parts often fail faster in these situations.

Can it handle high temperatures?

Yes, it handles very high heat well. It works fine up to about 1600°C. Metal parts soften or melt at lower temperatures. Avoid sudden temperature changes. Quick heating or cooling can cause cracks. This is thermal shock.

Can you make custom shapes and sizes?

Yes, manufacturers can make custom parts. They form the ceramic powder precisely. Then they fire it at high heat. This sintering makes it very hard and dense. Tell them your exact needs. Dimensions, tolerances, surface finish matter.

Is it fragile?

It’s very hard, but it can break if hit hard. Handle it carefully during install. Avoid sharp impacts. Use proper tools. Don’t overtighten fittings. The ceramic won’t bend like metal. It needs correct mounting. This prevents chipping or cracking.

(Refractory High Purity Wear Resistant Al2o3 Alumina Ceramic Shaft Piston Plunger)

REQUEST A QUOTE

RELATED PRODUCTS

Molding Ceramic Wear and Corrosion Resistant Alumina Ceramic Piston Plunger Bushing Rod for High Pressure Pump

High Pressure Washer Alumina Ceramic Piston Al2O3 Ceramic Plunger Tube

Wear Resistance Al2O3 Alumina Ceramic Plunger

95% 99% Alumina Ceramic Plunger for Pump

High Precision 95 99 Ceramic Piston Pump Alumina Ceramic Piston Plunger Bushing Custom Processing Pressure Washer CNC Machining