Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

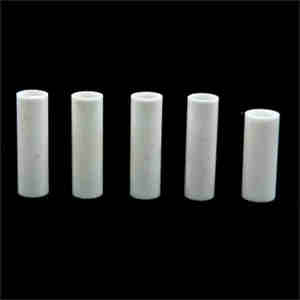

Overview of s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal

s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal)

Specifications of s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal

This customized ceramic plunger shaft piston combines high-purity light weight aluminum oxide with incorporated metal parts. It’s designed for demanding mechanical work. The core material is 95% to 99% alumina ceramic. This makes it extremely hard. It stands up to wear exceptionally well.

The alumina ceramic part endures severe abrasion. It manages heats conveniently. Temperature levels up to 1700 ° C are no problem. It won’t corrosion or corrode. Rough chemicals will not damage it. It stays dimensionally stable. Heat and stress do not warp it. Its electrical insulation properties are superb.

Accuracy machining is standard. We achieve limited resistances on sizes and sizes. Surface coatings are extremely smooth. This lessens friction during procedure. The ceramic pole incorporates flawlessly with steel components. Common steels consist of stainless-steel or specialized alloys. The metal parts offer strength and promote connections. Threaded ends or placing flanges are normal.

This crossbreed style supplies distinct benefits. The ceramic delivers unequaled wear life. It manages corrosive settings the metal alone can not. The metal offers structural support and simplifies setup. The result belongs that lasts a lot longer than all-metal choices. It minimizes downtime and maintenance expenses substantially.

These plunger shafts suit several hard applications. They work well in pumps and valves. Metering systems use them effectively. Industrial seals take advantage of their homes. Anywhere moving contact causes quick wear, this part succeeds. Modification is available. We tailor measurements, alumina grade, steel kind, and specific functions to your exact needs. Inform us your requirements. We build the accurate plunger shaft piston you require.

(s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal)

Applications of s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal

This custom bettor shaft makes use of 95% or 99% pure aluminum oxide ceramic. That makes it really hard. It withstands wear extremely well. This plunger piston takes care of laborious quickly. It lasts a lot longer than steel components. That saves money gradually.

The ceramic core resists chemical strike. Extreme acids and bases will not hurt it. It deals with heats conveniently. This makes it perfect for chemical handling pumps. It works well in hostile fluid meters also. Valves with destructive media require this sturdiness.

It will not rust or corrode. Water or salted air will not damage it. It keeps its smooth surface. This reduces friction considerably. Relocating components function smoother. Much less friction indicates much less energy squandered. Seals also last longer.

The alumina pole is precision ground. It accomplishes a very smooth surface. This accurate fit reduces leakages. It makes certain regular operation. Pumps supply consistent flow. Meters reveal exact analyses. Valves seal firmly every time.

Metal parts are connected firmly. Strong steel end caps or installations are common. Laser welding or unique brazing makes solid joints. This manages high stress without failing. The setting up works dependably sought after systems.

These plungers fit numerous commercial devices. Use them in high-pressure pumps. They work well in dosing systems. Metering pumps need this accuracy. Chemical injection systems rely on them. Shutoffs regulating abrasive fluids profit substantially. They are ideal for water therapy tools. They perform well in oil and gas applications. Semiconductor making utilizes them also. Any type of location requiring lengthy life and chemical resistance should consider them.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal

What are the purity levels?

These rods use high-grade alumina. Options are 95% or 99% pure. Higher purity means better performance. It offers superior hardness and chemical resistance. Choose based on your specific needs.

Why include metal parts?

Ceramic is brittle. Metal adds strength for mounting or impact. The metal end allows easy connection to other parts. This hybrid design combines ceramic’s wear resistance with metal’s toughness. It solves connection problems.

What temperatures can it handle?

These rods handle extreme heat well. Temperatures up to 1600°C won’t damage them. This makes them ideal for furnaces or high-heat machinery. They resist thermal shock effectively.

How does the surface finish help?

The surface is very smooth. This minimizes friction during operation. Less friction means less wear and longer life. It also prevents sticking or seizing in moving parts. Smoothness is key for plungers and pistons.

Can you customize sizes and metals?

Yes, we make custom sizes and shapes. Tell us your exact dimensions. We also use different metals like stainless steel. The metal part is designed to fit your application perfectly. Get the exact plunger shaft you need.

(s Custom 95 99 Aluminum Oxide Alumina Ceramic Rod Plunger Shaft Piston With Metal)

REQUEST A QUOTE

RELATED PRODUCTS

High Precision Ceramic Spool 99.7% Alumina Ceramic Plunger for Pump

99 High Purity Alumina Ceramic Piston Plunger for Valve

Wear and Corrosion Resistant 99% Al2o3 Alumina Ceramic Plunger with Metal for Pump

Customized Processing of Ceramic Plunger Pump Rod and Tube Injection Pump 95 99 Alumina Ceramic Pump Piston Column

High Polished 99% Alumina Zirconia Machinable Ceramic Bars Plungers Rods