Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

Overview of Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger

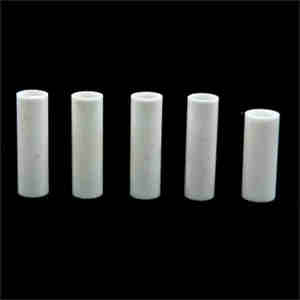

Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger is engineered from 99%+ pure aluminum oxide (Al₂O₃), delivering unmatched durability and precision for demanding industrial applications. Designed to operate in extreme conditions, these plungers excel in high-wear, high-temperature, and corrosive environments, making them perfect for pumps, valves, fuel injection systems, and chemical processing equipment.

Features of Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger

Superior Wear Resistance – Outlasts metal plungers in abrasive environments.

High-Temperature Stability – Maintains integrity up to 1600°C.

Corrosion & Chemical Resistance – Immune to acids, alkalis, and solvents.

Extreme Hardness (Hv 1500+) – Minimizes friction and extends service life.

Precision Machined – Tight tolerances for smooth, leak-free operation.

Customizable Designs – Available in various diameters, lengths, and surface finishes.

(Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger)

Specifications of Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger

This alumina ceramic pump piston is made from Al2O3. It includes over 95% aluminum oxide. This product is incredibly tough. It gauges around 80 HRA on the Rockwell scale. This high solidity offers excellent wear resistance. The piston surface puts on down a lot slower than steel parts. It substantially expands the pump’s service life. Lowered wear implies much less constant component substitute. This conserves downtime and upkeep prices.

The piston surface is very smooth. Its surface roughness (Ra) is usually below 0.2 micrometers. This smooth coating decreases rubbing inside the pump. Lower friction enhances efficiency. It also minimizes heat generation. Less warmth helps the pump run colder.

Alumina ceramic withstands corrosion well. Solid acids and alkalis do not harm it easily. This makes the piston ideal for rough chemical environments. It works reliably with corrosive liquids. It also holds up against erosion from abrasive bits. This is essential in slurry pumps.

The piston is manufactured to limited dimensional tolerances. Precision machining guarantees a perfect fit. This specific fit prevents leaks. It preserves constant pump stress. The piston keeps its form under tons. Dimensional stability is critical for reputable pump operation.

Alumina ceramic takes care of heats. It does well even in warm problems. It also stands up to thermal shock. Sudden temperature modifications are less most likely to cause cracking. This reliability is very important sought after applications.

These specs make the alumina ceramic piston ideal for laborious. It is made use of in high-pressure water jet pumps. It is found in oilfield devices. It serves in chemical processing pumps. It works well in abrasive slurry pumps. It runs properly in numerous commercial machinery.

(Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger)

Applications of Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger

Alumina ceramic pump pistons offer outstanding wear resistance. This material deals with rough liquids well. It lasts much longer than steel parts in difficult problems. The extreme hardness of alumina ceramic protects against damaging and erosion. This decreases downtime for maintenance. You save cash on substitutes.

Chemical resistance is another essential benefit. Alumina ceramic won’t rust like metals. It withstands acids, alkalis, and solvents. This makes it optimal for chemical handling pumps. You get dependable performance in hostile media. Parts remain intact much longer.

The smooth surface area coating matters. Alumina ceramic pistons are very brightened. This creates a much better seal with cylinder wall surfaces. Leak lowers dramatically. Pump effectiveness boosts. Regular flow rates are easier to preserve.

High-temperature stability is very important. Alumina ceramic deals with extreme warm. It does not deform or deteriorate easily. This matches demanding applications like hot oil transfer. Efficiency remains secure under thermal anxiety.

These pistons function well in lots of sectors. Oil and gas extraction uses them for mud pumps. Mining relies on them for slurry transportation. Nuclear power plant utilize them in boiler feed pumps. Chemical plants depend on them for dosing corrosive fluids. Water therapy facilities gain from their corrosion resistance. The low rubbing lowers power consumption.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger

What makes alumina ceramic pump pistons resist wear?

Alumina ceramic is very hard. This material handles friction well. Abrasive particles scrape softer materials. Alumina ceramic resists this scraping. It keeps its shape longer than metal. This hardness causes less wear over time.

Where are these ceramic pistons usually used?

These pistons work best in tough pumping jobs. They handle liquids with sand, ash, or chemicals well. Industries like mining, power plants, and chemical processing use them. They fit pumps moving slurries or corrosive fluids. Metal pistons fail quickly in these conditions.

Why pick ceramic over metal for a pump piston?

Ceramic pistons last much longer. Abrasive fluids wear down metal pistons fast. Ceramic resists this wear better. It also handles strong chemicals without rusting. This reduces pump downtime. You replace pistons less often. It saves money long-term.

Is installing a ceramic piston different?

Installation is similar to metal pistons. Care matters during handling. Ceramic is hard but can crack if hit hard. Avoid dropping it. Follow the pump maker’s torque specs. Correct installation prevents early damage. Proper seals are also important.

Do these ceramic pistons need special care?

These pistons need very little extra care. Their wear resistance means less maintenance. Regular pump checks are still important. Look for seal leaks or unusual vibrations. Keep pumping fluids within the design limits. The ceramic part itself rarely needs attention.

(Wear Resistance Alumina Ceramic Pump Piston Al2O3 Ceramic Plunger)

REQUEST A QUOTE

RELATED PRODUCTS

High Pressure Small Dose Liquid Filling Alumina Ceramic Plunger Pump Zirconia Ceramic Piston Plunger Pump

Alumina Plunger for Washing Machine Components Parts Ceramic Components

High Precision Yttrium Stabilized Industrial Alumina Zirconia Ceramic Plunger Pump Ceramic Rod With Stainless Steel

High Purity Cylinder Al2o3 Alumina Piston Plunger for Precision Metering Pump

99 High Purity Alumina Ceramic Piston Plunger for Valve