Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

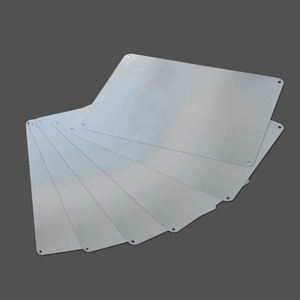

Overview of 95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc

95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of 95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc)

Specification of 95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc

Alumina ceramic plates are extremely difficult and strong. They stand up to heat extremely well. You locate them in several commercial usages. These plates are made from light weight aluminum oxide. Light weight aluminum oxide is a technical ceramic product. The pureness degrees issue. Usual choices are 95%, 96%, and 99% Al2O3. Greater pureness typically means much better performance.

95% alumina plates supply excellent value. They are solid and take care of heat well. They stand up to wear and chemical attack efficiently. These plates work accurately for lots of jobs. 96% alumina is an action up. It gives somewhat better stamina. It uses better resistance to chemicals. It takes care of higher temperature levels a bit far better than 95%.

99% alumina plates are leading entertainers. They give optimal solidity and strength. They hold up against the highest temperatures. Their electric insulation is superb. They resist chemical corrosion best. They reveal less wear with time. They are the option for requiring problems.

All these alumina plates share vital advantages. They are very hard. They are solid mechanically. They protect power quite possibly. They deal with severe warm quickly. They stand up to most chemicals strongly. They last a long period of time without wearing down. They stay dimensionally steady under stress.

You see these plates used in many places. They work as electrical insulators. They work as furnace linings. They are heat spreaders. They are wear-resistant surfaces. They are components in semiconductor tools. They are components in chemical processing. The 95% and 96% grades suit cost-sensitive usages well. The 99% quality fits critical, high-performance demands. Picking the ideal pureness depends on your specific demands and spending plan.

(95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc)

Applications of 95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc

Alumina ceramic plates are very hard and strong. People use them where normal materials fail. These plates come in different purity levels. Common choices are 95%, 96%, and 99% Al2O3. Higher purity usually means better performance. Each grade suits specific jobs.

95% alumina plates are cost-effective. They offer good strength and wear resistance. Factories use them for wear parts. They line chutes and hoppers handling abrasive materials. They work well as heat-resistant surfaces. Electronics use them as insulating substrates. They are common in furnace fixtures.

96% alumina plates perform slightly better. They have improved strength over 95% grade. They resist chemical attack better too. This makes them good for pump seals and valve seats. They handle corrosive chemicals well. They are used in medical equipment parts. They serve as durable liners in heavy machinery. They are reliable insulators in spark plugs.

99% alumina plates are top performers. They offer the highest purity level. They provide excellent hardness and strength. They resist extreme heat very well. They are highly resistant to chemical corrosion. They have very low electrical conductivity. Semiconductor manufacturing needs them. They are essential for wafer processing equipment. High-temperature kilns use them as setters. Precision laser systems use them for components. Advanced medical implants use this grade. Demanding laboratory equipment relies on them. They are vital for critical aerospace applications. They are used in high-power electrical insulators.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc

What are alumina ceramic plates?

Alumina ceramic plates are hard discs made from aluminum oxide. They handle high heat well. They resist chemicals effectively. They are strong mechanically. Common purities are 95%, 96%, and 99% Al2O3. Higher purity usually means better performance.

Why choose 95%, 96%, or 99% purity?

The purity level matters. It changes the disc’s properties. 95% alumina discs are cost-effective. They are good for general industrial jobs. 96% offers a balance. It has better strength than 95%. It is cheaper than 99%. 99% alumina is top quality. It has the highest strength. It resists wear best. It handles very high temperatures best. It insulates electricity best. Use 99% for demanding tasks.

Where are these ceramic discs used?

These discs serve many industries. Use 95% plates for wear parts. Use them for basic insulation. Use 96% plates for pump seals. Use them for valve components. Use 99% plates for semiconductor tools. Use them for high-power electronics. Use them for critical furnace parts. Purity matches the job’s needs.

How tough are these plates?

Alumina ceramic plates are very hard. They are harder than steel. They resist scratching well. They resist wear well. Higher purity makes them tougher. 99% alumina is the hardest. It lasts longest under friction. It handles impacts better than lower grades. But ceramics can crack under sudden force. Handle them carefully.

What about heat and electricity?

These discs excel with heat. They withstand over 1500°C. Higher purity handles more heat. 99% alumina performs best. They are excellent electrical insulators. They block electricity effectively. Higher purity insulates better. They transfer heat well also. This makes them ideal for hot, electrically active environments.

(95% 96% 99% Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate Disc)

REQUEST A QUOTE

RELATED PRODUCTS

Porous Round and Square Alumina Honeycomb Ceramic Plate square Ceraimc Filter Plate

High Purity and Density Alumina Ceramic Plate

Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

Hard Panel III & IV Ceramic Plate Alumina Silicone Carbide PE 3 4 Level BR5 Strike Face Armor Plate Tactical Vest Plate Carrier

High Alumina Ceramic Plate High Temperature Resistance Hexagon Mosaic Alumina Ceramic Tiles