Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

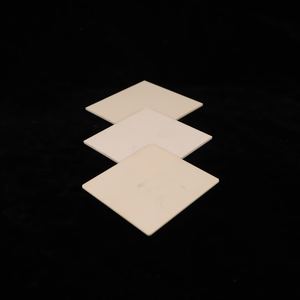

Overview of 99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate

99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of 99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate)

Specification of 99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate

This alumina ceramic plate offers superior sturdiness. It includes 99% pure light weight aluminum oxide. This composition makes it very hard. Its hardness comes close to that of diamonds. This solidity offers it excellent wear resistance. It endures abrasion much better than steel. This plate is ideal for rough commercial atmospheres. Believe mining equipment, slurry pumps, and power generation parts. It considerably prolongs the lifespan of machinery parts revealed to constant friction.

This plate additionally works as efficient ballistic defense. Its extreme solidity shatters inbound projectiles upon influence. This action damages the bullet apart. A strong support material captures the fragments. This support layer stops the bullet pieces. It stops hazardous spalling. With each other, the ceramic and support take in the effect energy. This combination shields workers and crucial devices. It antagonizes rifle hazards and covering pieces.

The product flaunts impressive technical residential or commercial properties. It maintains stamina at extremely heats. It resists corrosion from acids and antacids. It does not perform electrical power. It is non-magnetic. These residential properties make it flexible. It carries out reliably popular chemical plants, electric applications, and high-heat setups.

Available densities vary from 5mm approximately 25mm. Thicker plates give greater ballistic security degrees. Usual dimensions are 100x100mm or 150x150mm ceramic tiles. Bigger personalized dimensions are feasible. Installation normally involves bonding to a metal or composite support plate. This produces a robust armor system. It takes care of temperature levels approximately 1600 ° C constantly.

(99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate)

Applications of 99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate

People use 99% alumina ceramic wear-resistant plates since they are unbelievably hard and challenging. They last a lot longer than steel in rough conditions. This saves money and downtime. Mining business install these plates in chutes, receptacles, and conveyor systems. Home plates secure tools from obtaining used down by unpleasant ore and rock. Mineral processing plants utilize them in cyclones and pipelines. The ceramic handles sand and slurry without wearing out swiftly. Nuclear power plant count on these plates in coal pulverizers and ash handling systems. Home plates resist disintegration from coal dust and fly ash. Steel mills use them in blast heaters and product transfer points. They stand up to high warm and hefty effect from raw materials.

The same toughness makes alumina ceramic great for shield. It quits bullets and pieces properly. Soldiers wear body shield plates made from this ceramic. It shields against rifle fire and shrapnel. Car armor makes use of these plates also. They shield employees in military transportations and airplane. Police police officers use alumina ceramic plates in their vests. It provides crucial protection against handgun and rifle dangers. Safety setups embed these plates in wall surfaces and guard posts. They quit bullets from penetrating critical areas.

The material is really dense and difficult. It shatters bullets on effect. This soaks up the power and quits infiltration. A support layer captures any damaged items. This combination offers reliable defense. Alumina ceramic shield is lighter than steel shield. This permits far better movement. People can wear it longer without fatigue. Automobiles get much less weight. The plates function well against numerous usual threats. They supply a great equilibrium of protection and weight. This ceramic is a proven service for requiring work. It manages hefty commercial wear and major ballistic dangers. Its efficiency makes it a trusted option worldwide.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate

What is alumina ceramic used for?

99% alumina ceramic plates resist extreme wear. They protect machinery in tough industries. Mining equipment, power plants, and steel mills use them. They handle abrasion, impact, and high heat well. This extends equipment life significantly.

How tough is alumina ceramic armor?

Alumina ballistic plates offer very good protection. They stop bullets like rifle rounds effectively. The ceramic breaks the bullet on impact. A strong backing layer catches fragments. This combination saves lives in military and police gear.

Why choose alumina ceramic over steel?

Alumina ceramic beats steel in key areas. It is much harder, resisting abrasion better. It weighs only about half as much as steel. This reduces strain on equipment and people. It also resists corrosion and high temperatures superbly.

How are these ceramic plates installed?

Installation depends on the application. Wear plates often bolt or bond directly onto machinery surfaces. Ballistic plates fit into carriers or vests. Proper installation is critical for performance. Follow the manufacturer’s instructions exactly.

Does alumina ceramic need special care?

These plates require minimal maintenance. Their hardness makes them very durable. Avoid dropping them on hard edges. Check ballistic plates after any impact. Replace plates if cracks or major chips appear.

(99% Alumina Ceramic Wear-Resistant Plate Alumina Ballistic Ceramic Armor Plate)

REQUEST A QUOTE

RELATED PRODUCTS

Hexagonal Silicon Carbide Insert Plate Sheet High Hardness SiC Alumina Ceramic Tiles Plate for

Supply 15mm, 17mm, 21mm Alumina Ceramic Valve Disc Plate For Water Tap

Al2O3 Alumina Engineering Ceramic Thin Substrate / Sheet / Plate / Board

Tactical Equipment PE 3A Armored Panel Tactical Vest Insertion Plate 4IV Ceramic Plate Alumina Silicon Carbide

Alumina Boron Carbide PE Weighted Ceramic Vest Plate Protection Plates IV