Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

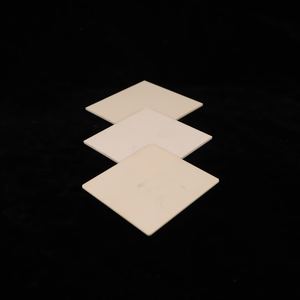

Overview of 99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component

99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of 99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component)

Specification of 99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component

This alumina ceramic plate utilizes 99% pure alumina product. It offers extraordinary efficiency in demanding industrial settings. The plate features numerous precisely machined openings. These holes are critical for its function. High pureness alumina supplies impressive hardness. It stands up to wear very well. This material withstands very high temperatures. It remains steady and useful under extreme warmth. Outstanding electric insulation is another vital advantage. This prevents electrical failures in delicate applications. Chemical resistance is a significant advantage. Home plate takes care of harsh compounds dependably. It will not degrade conveniently.

The plate itself is a flat, inflexible element. Its multi-hole style serves details purposes. Openings enable specific fluid flow control. They allow precise gas distribution. Components can be securely placed through them. The holes are crafted with high precision. Their dimension is tightly regulated. Placement is precise. This precision is essential for consistent results. Surface surface is extremely smooth. A smooth surface minimizes rubbing. It prevents particle accumulation. This guarantees trusted, long-term procedure.

Production uses innovative strategies. These warranty dimensional security. Home plate won’t warp or change shape easily. It maintains its exact kind under load. This stability is critical for high-precision usages. Applications are widespread. It functions well in semiconductor handling tools. It works accurately in furnace fixtures. Laser innovation gain from its residential or commercial properties. Sensing unit systems utilize it effectively. Chemical handling devices relies on its resistance. The plate stands out where various other materials fail. It executes under warmth, wear, and rust. Regular opening geometry is vital. It ensures repeatable procedure performance each time. Quality control is strenuous throughout manufacturing. This supplies a reputable industrial component.

(99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component)

Applications of 99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component

This 99% alumina multi hole ceramic plate is a high-precision industrial element. It is made from extremely pure light weight aluminum oxide. This product offers outstanding buildings. It handles extreme warm well. It withstands chemical assault highly. It wears gradually even under severe conditions. It stays flat and steady under warm and stress. Its electrical insulation is really trustworthy.

The exactly drilled holes are essential. Their size, setting, and spacing are regulated snugly. This accuracy is important for requiring tasks. These plates relocate delicate components like silicon wafers in semiconductor factories. The openings link to vacuum systems. This delicately lifts and positions vulnerable things without damage. Contamination is decreased.

Chemical handling plants use these plates also. They function as filters or assistance frameworks. They stand up to destructive fluids and gases. The inert product doesn’t respond. It keeps processes tidy. The openings allow fluids or gases to go through in a controlled means. High temperatures are not an issue.

These plates handle warm efficiently in electronics. They hold power elements. They spread out warmth far from sensitive components. The ceramic doesn’t carry out electrical power. This protects against short circuits. The security stops warping. Connections stay safe and secure.

Heating system and kiln procedures count on these plates. They hold items throughout high-temperature firing. Home plates endure repeated heating and cooling cycles. They resist thermal shock. They supply stable assistance. Product quality stays constant.

Laser systems use them as secure placing platforms. The openings precisely position optical elements. The ceramic does not misshape under laser energy. Alignment remains exact. Measurement devices need stable recommendations. These plates supply that stable base. Sensors install firmly. Analyses remain accurate.

The mix of purity, precision openings, and alumina’s toughness makes this plate versatile. It fixes difficult troubles in innovative manufacturing. It boosts integrity and efficiency. It lasts longer than steel or plastic alternatives. It handles settings where other products fail.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component

What material is this ceramic plate?

It’s made from 99% pure alumina ceramic. This high purity means it’s incredibly strong and resists wear exceptionally well. Alumina ceramic handles heat very effectively. It also withstands chemical corrosion. These properties make it perfect for tough industrial jobs.

Where is this plate typically used?

You find these plates in many demanding settings. They work well in semiconductor manufacturing equipment. They are common in precision laser systems. Chemical processing plants rely on them. Any application needing extreme durability and heat tolerance uses them. They hold parts securely without degrading.

How precise are the hole sizes and locations?

We achieve very high precision. Hole diameters and positions are controlled extremely exactly. Tolerances are often within a few microns. This level of accuracy is critical for aligning components perfectly. It ensures consistent performance in automated machinery. We guarantee the specs meet your exact needs.

Is this plate fragile?

Alumina ceramic is very hard and strong. It resists scratching and abrasion superbly. It handles rapid temperature changes well too. However, like most ceramics, it can break if hit hard or dropped. Handle it carefully during installation. Once mounted securely, it performs reliably under harsh conditions.

Can I get custom hole patterns or sizes?

Yes, we specialize in custom orders. Tell us your specific hole sizes. Tell us the exact pattern layout you require. Tell us the overall plate dimensions and thickness needed. We manufacture plates to match your unique design. We use advanced processes to ensure precision.

(99% Alumina Multi Hole Ceramic Plate High-Precision Industrial Ceramic Component)

REQUEST A QUOTE

RELATED PRODUCTS

99% Al2O3 Ceramic Machined Block Part High Temperature Wear-Resistance Durable Alumina Ceramics Plate

MCH Alumina Ceramic Plate Heating Element with 5V 7.4V

Insulating Refractory Beige Al2O3 Alumina Ceramic Disc Plate Biscuit

Insulation Aluminum Nitride Sheet Plate AlN Alumina Ceramic Substrate Plate Tube

High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate