Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

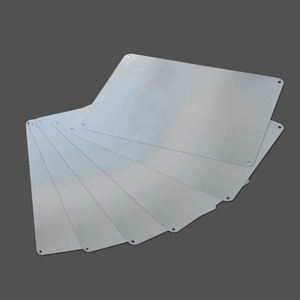

Overview of Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics

Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics)

Specification of Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics

Alumina ceramic arm robots take care of semiconductor wafers. These robots make use of industrial ceramic plates made from alumina. Alumina ceramic is really difficult. It withstands wear incredibly well. This material takes care of continuous rubbing in wafer processing equipments. Alumina ceramic keeps very clean. It does not lose fragments. Bit contamination damages wafers. Clean production atmospheres are important. Alumina ceramic meets this requirement completely. It additionally stands up to chemical attack. Extreme chemicals tidy wafers. Alumina ceramic plates stand up to these chemicals without damages.

The ceramic arms hold wafers firmly. Precision is vital. Wafer surfaces are delicate. Any scratch creates failing. Alumina ceramic gives a smooth, non-abrasive surface area. Robotics relocate wafers between process terminals. Accuracy is measured in microns. Alumina ceramic parts keep precise dimensions. They don’t warp with temperature adjustments. Thermal security is vital. Process temperature levels differ. Alumina ceramic carries out dependably through these shifts.

Electrical insulation is one more crucial benefit. Alumina ceramic does not perform electricity. This protects against electric shorts near sensitive circuits. Fixed cost accumulation threatens. Alumina ceramic minimizes this risk. The product is also very strong. It sustains wafers firmly without flexing. Breakage threats go down dramatically. Lengthy service life lowers machine downtime. Manufacturing facilities need consistent procedure. These ceramic elements supply that integrity. They are crucial parts in contemporary semiconductor fabs. Wafer handling demands excellence. Alumina ceramic arms offer the essential efficiency.

(Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics)

Applications of Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics

Alumina ceramic arm robots are essential for wafer handling in semiconductor plants. Semiconductor porcelains must fulfill extreme needs. Alumina ceramic industrial plates and robotic arms deliver essential performance. Steel components cause severe troubles. Tiny steel particles flake off. These particles pollute the delicate silicon wafers. Contamination damages the wafers. This leads to pricey manufacturing losses and reduced yields. Alumina ceramic resolves this contamination issue. The material is incredibly difficult. It stands up to wear extremely well. Really few particles damage free during procedure. The surface area stays smooth over time. This smoothness protects against wafer scratching. Scrapes damages circuit patterns. Alumina ceramic is chemically inert. It endures rough cleaning chemicals easily. Cleaning occurs often in cleanrooms. The product doesn’t respond with process gases either. This chemical security is important. Electrical insulation is one more crucial benefit. Alumina does not carry out power. This stops electrical shorts or disturbance. Shorts damages delicate digital components on the wafer. Warm resistance is important as well. Alumina deals with high procedure temperature levels dependably. Efficiency doesn’t break down under thermal stress and anxiety. Robotic arms need exact motion. Alumina ceramic components are dimensionally stable. They don’t warp or broaden dramatically with temperature changes. This stability ensures precise, repeatable wafer positioning. Exact placement is critical for high-density chip production. Cleanrooms need ultra-low particle generation. Alumina ceramic arms and plates succeed here. They reduce contamination threats successfully. This reliability directly enhances production result and top quality. Semiconductor makers count on these innovative ceramic solutions. They make it possible for efficient, high-yield wafer manufacture. Alumina ceramic components are the relied on selection for contemporary semiconductor automation.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics

Here are 5 FAQs about Alumina Ceramic Arm Robots for Wafer Handling:

1. Why use alumina ceramic for robot arms handling wafers?

Alumina ceramic is very hard. It resists wear extremely well. This is crucial. Robot arms touch wafers constantly. Metal arms wear down over time. Worn metal sheds tiny particles. These particles ruin wafers. Alumina ceramic stays smooth much longer. It doesn’t shed particles. This keeps wafers clean. Clean wafers mean fewer defects.

2. How does ceramic prevent contamination?

Alumina ceramic is non-porous. Liquids and gases cannot soak into it. This is important. Process chemicals won’t get trapped inside the arm. Trapped chemicals could later leak out. They would contaminate other wafers. The smooth ceramic surface is also easy to clean thoroughly. No tiny holes hide dirt.

3. Can it handle high temperatures?

Yes. Alumina ceramic handles extreme heat very well. Semiconductor processes often use high temperatures. Metal arms can warp or weaken in this heat. Warped arms damage wafers. Ceramic stays stable. It keeps its shape and strength even in hot cleanrooms. This reliability is essential.

4. Is maintenance difficult?

No. Alumina ceramic needs very little maintenance. Its hardness means it wears down incredibly slowly. You don’t need to replace parts often. You don’t need constant lubrication either. Lubricants can create contamination risks. The ceramic runs clean and dry. This saves time and cost.

5. Why not use other ceramics or metals?

Metals wear and shed particles. They also corrode from chemicals. Other ceramics might not be as hard or pure. Alumina offers the best balance. It provides extreme hardness, excellent purity, and great thermal stability. It directly touches delicate wafers. Only alumina ceramic reliably meets all the strict requirements for cleanliness and durability in wafer handling.

(Alumina Ceramic Arm Robot for Wafer Handling Industrial Ceramic Plates Semiconductor Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

High Purity Alumina Ceramic Slide Block Plate Alumina Ceramic Part Slot Block

95 Alumina Ceramic Plates Porous Ceramic Plates OEM Supply

Customize 95%alumina Ceramic Filters Plate square Alumina 30um Porous Disc

Ceramic Base High Precision Alumina Ceramic Polishing Plate Substrate