Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

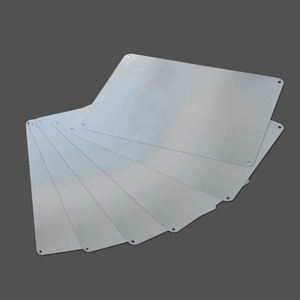

Overview of Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors

Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors)

Specification of Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors

This custom high pureness insulation big round ceramic alumina sheet is created difficult semiconductor work. It is an Al2O3 plate. The alumina pureness is really high, usually 99.5% or more. This high purity quits contamination. It keeps sensitive semiconductor procedures safe. The material is a solid electrical insulator. This quits current leakages. It protects fragile electronic parts. The sheet handles severe warmth well. It functions penalty in high temperature vacuum chambers. Thermal shock resistance is excellent. Sudden temperature level changes won’t break it conveniently. The surface is really smooth. This is necessary for a good vacuum cleaner seal. It aids the sucker grip wafers firmly without slipping. The vacuum fool application requires this level, smooth surface area. It makes certain reliable wafer holding throughout handling and processing. Mechanical stamina is high. The plate stands up to damaging and breaking. It lasts a long period of time under regular use. Chemical resistance is outstanding. Usual process chemicals and cleaning representatives don’t damage it. This durability lowers replacement expenses. We make these plates in huge round shapes. The dimension is custom-made. Inform us the diameter and thickness you require. We can make plates for your certain equipment or device. These alumina sheets are essential parts. They are made use of in semiconductor wafer production tools. They work in vacuum cleaner environments. They hold wafers safely for etching, deposition, and inspection actions. Precision and dependability are vital here. This alumina plate supplies that performance. It fulfills the stringent demands of semiconductor manufacturing.

(Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors)

Applications of Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors

These custom-made high purity alumina plates are crucial for innovative semiconductor manufacturing. They are made from Al ₂ O three ceramic. This product is extremely pure, frequently 99.5% or greater. High pureness prevents contamination of delicate silicon wafers. Contamination damages chips. These plates provide superb electric insulation. This is vital in high-voltage semiconductor tools. They deal with extreme heat well. Semiconductor procedures run very hot. The alumina stays steady. It does not warp or fracture quickly. This dimensional security is crucial for precision equipment.

The big round ceramic sheets function as strong, flat surface areas inside machines. They protect electric elements successfully. They endure plasma settings common in etching chambers. They resist chemical attack from harsh process gases. This longevity ensures long life span. It decreases pricey equipment downtime. Customized sizes and shapes fit certain device designs completely. Accurate fitting prevents spaces. Voids trigger process concerns.

Alumina vacuum cleaner fools are critical for wafer handling. They gently lift and move delicate silicon wafers. The high pureness surface touches the wafer straight. It leaves no residues. The suckers require superb thermal stability. Wafer processing entails rapid temperature level adjustments. The fools have to not break down. They preserve a solid vacuum cleaner grasp accurately. Consistent grasp stops wafer drops. Wafer drops mean lost production. Personalized develops suit robot arm user interfaces precisely. Precise matching makes certain smooth automation. These fools are tough. They endure consistent use in cleanrooms. Cleanrooms need high reliability. Alumina fulfills this demand.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors

What’s the main benefit of your alumina sheets?

Our Al2O3 plates offer extremely high purity. This is critical for semiconductor tools. Impurities can ruin sensitive processes. Our sheets keep things clean. They prevent contamination effectively.

Can I get exact sizes for my equipment?

Yes. We make big round ceramic sheets to your precise measurements. Tell us the diameter and thickness you require. We cut them accurately. This ensures a perfect fit in your machine.

How well do they handle heat?

These alumina plates resist very high temperatures. They manage sudden temperature changes well. They won’t crack easily under thermal stress. This stability protects your semiconductor processes.

Will they work with vacuum systems?

Absolutely. The material structure is dense. It prevents gas leaks under vacuum. Our alumina vacuum suckers provide reliable sealing. They maintain the needed vacuum pressure consistently.

Is the surface smooth enough?

We control the surface finish carefully. You get a very flat, smooth plate. This avoids particle generation. It ensures safe handling of delicate wafers. We achieve the low surface roughness (Ra) you specify.

(Custom High Purity Insulation Big Round Ceramic Alumina Sheet Al2o3 Plate Alumina Vacuum Sucker for Semiconductors)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Customized Photovoltaic Alumina Ceramic Plate Solar Panel Ceramic Pad

Al2O3 Ceramic Large Size Aluminium Oxide Ceramic Plates and Discs Alumina Ceramic Round Plate

Round White Alumina Ceramic Disc Plate for Electric Heating element

Holes in the Center Sintered Alumina Ceramic Plates

Micro Porous Ceramic Filter Plate /Alumina Ceramic Disc Plate for Filter