Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

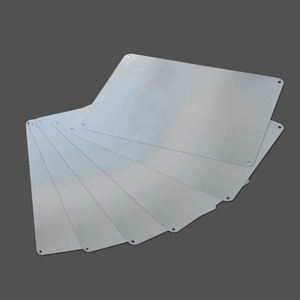

Overview of Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery

Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery)

Specification of Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery

Heavy machinery encounters hard problems. Customized alumina ceramic armor plates provide strong security. These plates are made from high-purity aluminum oxide. This material is really difficult. It withstands scrapes and use very well. Alumina ceramic is likewise extremely stiff. It doesn’t bend under pressure. This tightness assists soak up impact power properly. The plates take care of high temperatures without failing. Warm from machinery or friction will not damage them. They withstand chemical rust as well. Extreme liquids or solvents won’t eat away at the ceramic.

We make these plates to your exact demands. You tell us the shapes and size required. We generate plates suitable your specific equipment completely. This consists of excavators, excavators, loaders, and various other heavy equipment. Thickness is a crucial aspect. We provide various thickness options. The ideal density relies on the risk degree. Thicker plates stop larger, faster projectiles or effects. We can likewise adjust the solidity grade. Various tasks need different levels of surface area toughness.

The production procedure ensures high quality. We utilize sophisticated pushing and sintering techniques. This creates a thick, consistent ceramic structure. No weak points exist in the last plate. We bond the ceramic to a hard backing product. This backing layer takes in shock. It stops the ceramic from cracking totally on impact. The backing holds pieces together. This multi-layer style offers superior security. It quits bullets, shrapnel, and flying debris. It shields versus hefty impacts from rocks or devices.

These personalized plates include crucial safety. They expand the life of your costly machinery. Operators stay more secure inside protected cabs. Downtime because of damage is minimized. Our plates satisfy market security standards. They are dependable defense for demanding industrial settings. The customized fit ensures no gaps in insurance coverage. Your machinery gets the protection it needs.

(Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery)

Applications of Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery

Customized mold alumina ceramic shield plates safeguard hefty equipment. This equipment encounters tough conditions daily. Rocks fly. Particles strikes hard. Abrasion uses components down. Alumina ceramic plates stop this damage. They are extremely hard. This firmness shields important parts. Think excavator pails. Excavator blades. Loader arms. Crusher linings. These locations take consistent hits. Standard steel flexes. Steel dents. Steel wears out quick. Ceramic shield lasts a lot longer.

These plates absorb effect power. They smash rocks. They disperse debris. This action saves the metal underneath. Your machine parts remain secure. This implies much less downtime. Repair work cost money. Shed job time costs more. Strong armor keeps machines running. Operators remain much safer as well. Flying fragments trigger injuries. Ceramic armor includes these threats.

Alumina ceramic is also light. Hefty equipment requires protection without extra weight. Including hefty shield strains engines. It burns much more gas. Lighter ceramic plates address this. They use leading security. They don’t slow down the maker down. Gas efficiency stays far better. Performance stays high.

Personalized molding is vital. Every equipment part is various. Every work has unique risks. Off-the-shelf plates frequently fit inadequately. Spaces leave vulnerable points. Customized plates healthy perfectly. They cover precisely where required. Designers develop them for particular effect zones. They match the specific contours of your pail or blade. This best fit provides the best defense feasible. It utilizes material effectively. No waste. Optimum coverage.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery

Customers often ask about our custom alumina ceramic armor plates for heavy equipment. Here are five common questions and answers.

Why use alumina ceramic for armor plates? Alumina ceramic is extremely hard. It resists abrasion and impact much better than steel. Heavy machinery faces constant wear from rocks, ores, and tough materials. Ceramic plates protect vital parts longer. This reduces downtime and repair costs.

What does ‘custom mold’ mean? It means we create ceramic plates shaped exactly for your specific machine part. We don’t offer only standard sizes. We make plates to fit complex curves, bolt patterns, and unique surfaces perfectly. This ensures complete coverage and optimal protection.

Are ceramic plates better than hardened steel? Yes, in most abrasive wear situations. Alumina ceramic is much harder than even the toughest steel. It lasts several times longer under severe conditions. Steel deforms under impact. Ceramic shatters energy, protecting the base metal underneath.

Will the ceramic break easily? It’s designed to absorb impact. Alumina ceramic is tough but brittle. It cracks under extreme force. This cracking absorbs the energy. The plate stays functional. Small cracks are normal. We design the plates to remain effective even after cracking. Replace the plate only if large pieces break off.

How are the plates attached? We offer several mounting options. Common methods include bolting through pre-formed holes in the ceramic and steel backing. We also use heavy-duty adhesive bonding. We design the mounting system with the plate shape. This ensures a secure, reliable fit for your application.

(Custom Mold Alumina Ceramic Armor Plates for Heavy Machinery)

REQUEST A QUOTE

RELATED PRODUCTS

Square Plate Heater 12V 30W Alumina Ceramic Resistor Heating Element

Aluminium Oxide Al2O3 Alumina Ceramic Polishing Plate with Fine Electrical Insulation

Wear Resistant Alumina Aluminum Oxide Al2O3 Ceramic Bulk Round Plate 95% 96% 99% for Industrial Use

96% Alumina Ceramic Substrate Plate 96 Al2O3 Aluminium Oxide Sheet

Hard Panel III & IV Ceramic Plate Alumina Silicone Carbide PE 3 4 Level BR5 Strike Face Armor Plate Tactical Vest Plate Carrier