Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

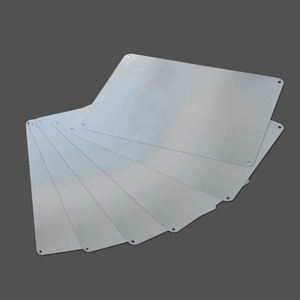

Overview of Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln

Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln)

Specification of Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln

This customized rectangular ceramic plate handles difficult problems. It is made from 95% alumina (Al2O3). This high alumina content gives it special strength. Home plate withstands wear effectively. It stays hard even under hefty rubbing. This indicates it lasts long in harsh spots. Its surface remains smooth over time. This safeguards various other components from damage.

The plate is likewise a great insulator. It holds warmth inside kilns successfully. This saves power. It manages high temperatures easily. It won’t split or warp from unexpected heat changes. This stability is crucial for consistent kiln operation. The plate keeps its form and toughness under warmth stress.

You can purchase this plate in your specific dimension. We make custom-made rectangle-shaped forms. Inform us the length and size you need. We likewise adjust the density as called for. This makes certain a best fit for your kiln configuration. Custom-made dimensions stop gaps and increase efficiency.

This ceramic plate is constructed for demanding kiln work. It works well for furnace cellular linings. It safeguards kiln autos and shelves. Use it for warmth treatment equipment. It fits sintering heaters completely. Home plate shields sensitive parts from heat and wear. It assists kilns run much longer with much less upkeep. Select this plate for reliable, high-temperature defense.

(Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln)

Applications of Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln

These custom-made rectangular alumina plates tackle difficult warmth difficulties. Their 95% Al2O3 ceramic make-up supplies significant efficiency. They stand up to using down incredibly well. This long life matters in penalizing industrial settings. They stand out as thermal obstacles. Warm doesn’t go through them conveniently. This insulation maintains warm where you require it. Power efficiency enhances dramatically. Heating system linings remain cooler on the surface. Employee security obtains an increase.

Handling abrupt temperature level swings is critical. These plates take care of thermal shock dependably. They will not fracture conveniently going from hot to cold quick. This stability is vital for duplicated home heating and cooling down cycles. Equipment lasts longer. Downtime decreases. Withstands chemical strikes. Endures physical effects. The material remains solid under tension. Personalized sizing guarantees a perfect fit for your specific kiln or furnace. This stays clear of gaps and weak points. Heat distribution remains uniform.

Kilns benefit considerably. Use them as sturdy racks or setters. They hold heavy ceramic pieces throughout firing. Regular results occur. Secure kiln cars and truck tops effectively. Line heater blocks or tiles reliably. High-temperature areas require durable security. These plates provide. Factories utilize them near liquified steel. They protect sensitive tools. Glass manufacturing relies upon them in annealing lehrs. Warmth treatment heaters depend upon their security. Powder processing requires reputable thermal obstacles. These plates strive.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln

What material is this ceramic plate?

It’s 95% alumina ceramic. Alumina means aluminum oxide. This high alumina content gives excellent performance. It handles extreme conditions well.

How hot can it get before failing?

This plate withstands continuous temperatures up to 1600°C. It handles short spikes even higher. Its low thermal conductivity insulates effectively. This makes it ideal for kilns and furnaces.

Why is it wear resistant?

The dense alumina structure is very hard. It resists abrasion and scratching exceptionally well. This protects surfaces like kiln furniture. It lasts much longer than softer materials.

Where can I use this alumina plate?

Use it directly in high-heat industrial settings. Common applications include kiln linings, furnace baffles, and heat treatment fixtures. It protects equipment from wear and extreme temperatures. These plates also work well as thermal barriers.

Can I get custom sizes and shapes?

Yes. We specialize in custom rectangular plates. Tell us your exact dimensions. We manufacture plates to your specific length, width, and thickness requirements. This ensures a perfect fit for your equipment.

(Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 Al2o3 Ceramic Board For Kiln)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Ceramic Sheet Industrial Ceramic Bearing Plate/Electronic Component Heating Calcination Ceramic Parts for Industrial Use

95 Alumina Ceramic Plates Porous Ceramic Plates OEM Supply

Alumina Ceramic Substrate for Industrial Applications Electrical Insulation Ceramic Plates Customizable Processing Service

Soft PE 3A Tactical Safety Vest Alumina Silicon Carbide Ceramic Plate Insertion 4IV Ceramic Plate Armored Panel Equipment

Thickness 0.635mm to 1mm 99% Al2o3 Alumina Ceramic Plate Substrate