Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

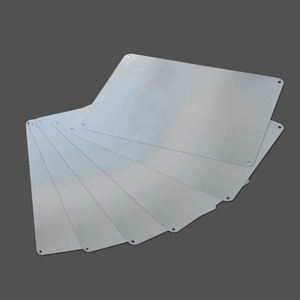

Overview of Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish)

Specification of Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

These are alumina ceramic parts. We make them making use of completely dry stress moulding. We device them specifically with CNC. The shapes include grooves, ports, discs, plates, and recipes. Alumina ceramic is very difficult. It withstands wear exceptionally well. It takes care of heats quickly. It doesn’t conduct electrical power. Chemicals rarely harm it. Dry pressing types the fundamental form. This approach packs ceramic powder securely. It makes use of high stress inside a mold. This creates solid, thick components before firing. Firing occurs in a kiln at high heat. This makes the ceramic difficult and permanent.

After firing, we use CNC machining. CNC devices reduced the ceramic precisely. They create exact grooves and slots. They form the edges perfectly. They make certain the surface area is smooth. This process attains tight tolerances. We control dimensions really exactly. The finish is great. This accuracy is important for components that fit together. Alumina ceramic is weak. Cautious machining protects against fractures. Experienced drivers manage this. They recognize how to collaborate with this product.

These components handle tough conditions. They work in high heat atmospheres. They resist chemical rust well. They provide electric insulation accurately. They last a very long time because they withstand wear. Typical usages are numerous. They operate in semiconductor production tools. They are components in furnace cellular linings. They work well in chemical pumps. They offer in medical devices. They are made use of in laser systems. They are found in wear plates. They are necessary in sensor real estates. They are type in electrical insulators. The specific form depends on the work. Grooves assist liquids or wires. Slots hold parts safely. Discs and plates give flat surface areas. Dishes contain products safely. CNC machining makes complex features possible. Dry pushed alumina offers the base toughness. This mix supplies trusted ceramic components.

(Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish)

Applications of Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

Dry stress moulding makes alumina ceramic blanks. CNC machining then shapes these spaces specifically. This procedure produces intricate ceramic components. These components consist of grooves, ports, discs, plates, and recipes. Alumina ceramic deals outstanding residential properties. It holds up against severe heat extremely well. It resists chemical deterioration efficiently. It is likewise a strong electrical insulator. Its firmness supplies wonderful wear resistance. These attributes make it suitable for demanding tasks.

Several industries utilize these personalized ceramic shapes. Electronic devices need shielding components. Alumina components isolate electric parts reliably. They take care of high voltages safely. Semiconductor devices use alumina plates and discs. These components make it through extreme processing environments. They resist plasma etching and high temperatures.

Industrial machinery calls for tough components. Alumina ceramic grooves and slots guide materials. They protect surfaces from abrasion. Use plates prolong devices life significantly. They decrease pricey downtime for upkeep. Alumina recipes offer high-temperature heaters. They hold materials during heat therapy. They stand up to thermal shock better than steel.

Medical tools benefit as well. Alumina discs work in accuracy instruments. They provide biocompatibility and chemical pureness. They are very easy to disinfect repetitively. Laser systems utilize alumina parts. They manage warmth and offer stable systems. The product does not warp under laser energy.

Automotive sensors depend on alumina insulators. They operate in warm engine compartments. They give secure electric efficiency. The completely dry pressure moulding offers a dense structure. CNC machining attains tight tolerances. This mix guarantees components fit perfectly. They perform consistently under stress and anxiety. These porcelains address troubles metal can not. They last longer in corrosive or high-wear setups.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish

Dry pressure moulding CNC machining makes alumina ceramic parts like groove slot round disc plate dish shapes. Here are common questions.

What is dry pressure moulding? It presses very fine alumina powder into a solid shape inside a mould. We use high pressure. This makes a compact “green” part before firing. The powder flows well. This gives uniform density.

Why use alumina ceramic? Alumina ceramic is very hard. It resists wear extremely well. It handles high heat easily. It does not conduct electricity. It resists chemical attack. These properties are vital for tough jobs. Think electronics, cutting tools, wear parts.

Why machine after moulding? We CNC machine the fired ceramic piece. Moulding gets close to the final shape. CNC machining makes exact sizes and smooth finishes. We cut precise grooves, slots, holes. We achieve tight tolerances. This ensures perfect fit.

Is this process cost-effective? Yes for complex shapes needing precision. Moulding forms the basic shape efficiently. CNC machining only removes a little material. Less waste happens. Less machining time saves money. Good for medium to high volumes.

Where are these parts used? Everywhere demanding tough, precise ceramics. Insulators in electronics need exact slots. Cutting tools need sharp edges. Wear plates need smooth surfaces. Semiconductor parts need chemical purity. Sensor housings need thermal stability.

(Dry Pressure Moulding Cnc Machining Alumina Ceramic groove Slot Round Disc Plate Dish)

REQUEST A QUOTE

RELATED PRODUCTS

Customizable 85% Alumina Ceramic Plate 130*30*40mm High Temperature Ceramic Plate Industrial Use with 12mm Hole

130*30*40mm High Temperature 85% Alumina Ceramic Plate Industrial Use with 12mm Hole Customizable Any Shape

Customized High Anti-Impact Alumina Ballistic Ceramic Armor Plate Boron Carbide Square Patterns Industrial Use Welding Cutting

High Temperature Industrial 95% 99% Al2O3 Alumina Ceramic Plate

Huto 1mm to 8mm Thickness Alumina Ceramic Structure Plate for Metal Powder Firing 100*100*2mm