Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

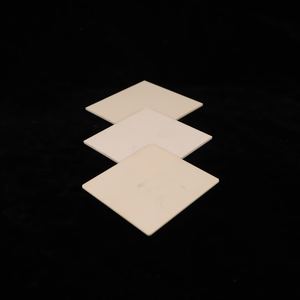

Overview of Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service

Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service)

Specification of Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service

This electrical MCH ceramic burner uses ring or disk shapes. It is developed with 96% alumina industrial ceramic plates. This material option is crucial. Alumina ceramic deals excellent electrical insulation. It holds up against really high temperatures. It resists thermal shock well. The heating units deliver quickly, even heating. They supply precise temperature control. This is important for requiring commercial tasks.

These heaters work successfully. They reach heats promptly. The operating array is wide. They handle temperatures approximately 1000 ° C or even more. Their power thickness is high. This suggests strong warm result from a small size. The alumina ceramic construction makes certain lengthy life. It takes on hard conditions. This consists of chemical direct exposure and physical wear.

A significant benefit is the personalized cutting service. We comprehend typical sizes don’t fit every demand. You need a certain shape or opening pattern. We can manufacture it. Provide your specific measurements or illustrations. We create the heating unit to match your devices completely. This gets rid of suitable problems. It optimizes home heating efficiency for your arrangement.

These MCH ceramic heating systems are made use of many locations. Semiconductor manufacturing requirements clean, dependable warmth. Medical tools require accurate thermal monitoring. Product packaging machinery utilizes them for securing processes. Analytical tools rely on stable temperature levels. Laboratory devices requires long lasting burner. Food handling lines utilize them for cooking or drying out. Plastic molding calls for regulated warm application. Their versatility and integrity make them necessary. They are a robust home heating option for intricate industrial requirements.

(Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service)

Applications of Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service

These MCH ceramic heating elements include ring-shaped disks made from tough 96% alumina ceramic. They warm up unbelievably fast and get to really heats. Their effectiveness saves energy contrasted to older heating unit types. These heaters are built strong. They resist corrosion from chemicals. They take care of high warm without damage. This makes them excellent for demanding commercial work.

You locate these heating units inside lots of devices. They work well in plastic molding tools. They warm injection molds equally. This guarantees plastic components develop correctly. Semiconductor producing relies upon them too. They supply specific heat for wafer handling. Heaters and kilns use them for regulated home heating areas. Food processing tools requires tidy, trustworthy heat. These ceramic heating units provide that. Medical tools utilize them for sterilization tasks. Lab equipment requires steady temperature levels. These heating systems provide that security.

The 96% alumina plates are vital. Alumina manages extreme heat fantastically. It doesn’t wear swiftly. Electrical energy moves through ingrained coils. The ceramic protects perfectly. Warmth transfers directly to your target. Little energy obtains wasted. This layout implies long life and low upkeep. You get consistent performance.

We provide custom reducing for these heating systems. Your application may require a details size. Maybe you need an unique opening pattern. We can form the ceramic disk to fit your maker precisely. Inform us your needs. We create the heater you require. This makes sure optimal warmth circulation. It assures the heating system integrates completely. Modification solves challenging home heating problems.

These heating units fit puts requiring fast, regional warmth. They work where space is restricted. Their toughness handles difficult settings. They are a wise choice for modern-day commercial heating.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service

What is this electric ceramic heating element?

This ring-shaped disk heater uses MCH technology. MCH stands for Metal Ceramic Heater. It features industrial plates made from 96% alumina ceramic. The design is a ring or disk shape. It generates intense heat efficiently.

How does this heater produce heat?

Electricity flows through a special resistance layer inside the ceramic. This layer heats up fast. The alumina ceramic plate transfers the heat directly to your target object. The heat transfer is very efficient. Little energy gets wasted.

What are the main advantages of this alumina ceramic heater?

Alumina ceramic offers excellent properties. It withstands very high temperatures. It resists thermal shock well. It provides good electrical insulation. The 96% purity alumina ensures long life and stable performance. Heat spreads evenly across the surface.

Can I get custom shapes and sizes?

Yes. We provide a custom cutting service. You need a specific shape? We can cut the alumina ceramic plate to match. You need a particular size? We can make it. Tell us your exact requirements. We will produce the heater to fit your application perfectly.

Any tips for installing this heater?

Ensure the heater surface makes full contact with your object. Good contact ensures the best heat transfer. Use suitable mounting methods. Clamps or brackets often work well. Make sure the electrical connections are secure. Follow standard safety procedures for electrical devices.

(Electric MCH Ceramic Heating Element Ring Shape Disk Heater with 96% Alumina Industrial Ceramic Plates-Custom Cutting Service)

REQUEST A QUOTE

RELATED PRODUCTS

Alumina Porous Ceramic Plates With 99 Alumina Ceramic Custom Products

99% Al2o3 Industrial Fine Honeycomb Ceramic Plate Alumina Ceramic Disc

White Round Block Wear Resistant High Hardness Al2o3 Alumina Ceramic Plate

95% Alumina/Al2O3 Alumina Ceramic Thin Plate/Alumina Ceramic Substrate

Tabular Alumina Tabular Alumina Plate Shaped Corundum Fine Powder for Electronic Ceramic Semiconductor Device