Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

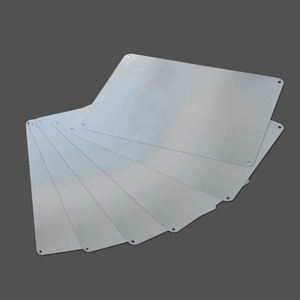

Overview of High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles

High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles)

Specification of High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles

Below’s the item content about High Aluminum Oxide Lining Plate Hexagon White High Put On Immune Alumina Porcelain Mosaic Shingles:

These are tough hexagon-shaped ceramic tiles created heavy wear. They are constructed to last in rough conditions. The material is high-purity aluminum oxide ceramic. This stuff is extremely difficult. It rates just below diamond on the hardness range. This severe hardness makes the ceramic tiles extremely immune to abrasion. They manage continuous scraping and grinding better than steel. Expect them to last many times longer than metal linings.

The tiles are intense white. They have a smooth, thick surface area. This surface stands up to material sticking to it. Points flow over it easily. This reduces rubbing. It likewise decreases power usage in devices like chutes or hoppers. The low rubbing aids prevent blockages. It keeps things relocating efficiently.

Each tile includes an unique six-sided shape. This hexagon style enables limited installation. The tiles lock together nicely. This creates a constant, seamless safety surface. There are no huge gaps for wear to start. The mosaic pattern spreads influence and use evenly. It shields the underlying steel structure effectively.

Installation is uncomplicated. You connect them utilizing solid sticky epoxy. You can also bolt them safely with pre-formed openings. This dual repairing method ensures they stay put. They won’t shift or come loose under vibration or effect. The floor tiles are perfect for lining tools in mining, nuclear power plant, concrete manufacturing facilities, and steel mills. Utilize them in chutes, shelters, pipes, cyclones, and transfer factors. They protect surfaces revealed to unpleasant materials like ore, coal, slag, or ash.

The primary requirements is the alumina material. It’s over 95%. This high purity assurances top efficiency. The floor tiles are really dense. They have low water absorption. This stops moisture damage. They resist chemical assault from acids or alkalis well. They deal with high temperatures without losing stamina. The ceramic tiles are non-sparking. This is an important safety and security function in explosive environments. They are also non-magnetic.

(High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles)

Applications of High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles

These high aluminum oxide lining plates feature hexagon-shaped white alumina ceramic mosaic ceramic tiles. They offer outstanding wear resistance. This makes them ideal for protecting tools in difficult commercial setups. They manage severe abrasion and influence damages well. Numerous sectors count on them.

Mining procedures utilize these floor tiles extensively. They line chutes, hoppers, and transfer factors. Ore and rock regularly move via these areas. The ceramic tiles shield the underlying steel structures. This prevents costly breakdowns and downtime. They considerably extend equipment life.

Nuclear power plant mount these tiles in coal handling systems. Coal is really abrasive. It wears down equipment quick. The floor tiles line shelters, feeders, and crushers. They withstand the constant scratching and effect. This reduces maintenance frequency and costs.

Concrete manufacturing facilities encounter similar difficulties. Resources like limestone and clinker are harsh. Conveyor systems, crushers, and mills need protection. These alumina ceramic tiles line these locations properly. They withstand the grinding activity of the materials. This keeps production running efficiently.

Steel mills benefit greatly also. They safeguard locations handling iron ore, sinter, and slag. These materials are hot and rough. The tiles keep their toughness in high-heat zones. They avoid disintegration in vital heater feed systems and air ducts.

Product handling equipment typically uses these ceramic tiles. Screw conveyors, mixers, and cyclones experience wear. The floor tiles supply a hard, smooth surface. This minimizes rubbing and material accumulation. Devices operates much more effectively. The hexagon shapes secure with each other firmly. This develops a smooth, long lasting barrier against wear.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles

Here are 5 common questions about High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles:

What makes these tiles resist wear so well? The key is the high aluminum oxide content. This material is extremely hard. It ranks just below diamond. This hardness directly fights abrasion. The tiles keep their surface intact under heavy wear. They handle constant scraping and impact much better than steel or rubber. This toughness extends their usable life significantly.

How do you install these mosaic tiles? The tiles come as small hexagon pieces. You attach them to a backing plate. This backing plate gets fixed to your equipment surface. Common methods include welding studs or using strong adhesive. The mosaic design allows installation on curved surfaces. The small size lets the tiles conform to bends. This provides protection on pipes, chutes, hoppers, and other complex shapes.

Are these tiles good against chemicals? Yes. The high alumina ceramic material is chemically inert. It resists attack from many acids and alkalis. This is important for harsh industrial settings. Chemical spills won’t easily damage the tile surface. The tiles work well in mining, power plants, cement factories, and chemical processing. They withstand both physical wear and chemical exposure.

What sizes are available? The individual hexagon tiles are typically small. Common sizes are around 17mm or 20mm across the flats. These small tiles form larger mosaic sheets. The backing plate size determines the overall sheet dimension. Standard sheet sizes exist. Custom sizes are often available. The small hexagon shape provides excellent impact resistance. It also allows easier installation on contours.

How long will these lining plates last? Their lifespan is much longer than steel linings. Expect 5 to 10 times the service life in severe abrasion zones. Actual life depends completely on your application. Factors include the type of abrasive material, impact force, and operating temperatures. Proper installation is critical. Correctly installed tiles deliver reliable, long-term protection. They reduce maintenance downtime and replacement costs.

(High Aluminum Oxide Lining Plate Hexagon White High Wear Resistant Alumina Ceramic Mosaic Tiles)

REQUEST A QUOTE

RELATED PRODUCTS

High Purity Alumina Bulletproof Plate Ceramic Plate

99% Alumina Ceramic Slabs Plate Sheet

High Purity 99 Round Alumina Honeycomb Ceramic Plate Aluminum Oxide Insulation Disc

96% Purity Alumina Ceramic Thin Plate

Aluminium Oxide Al2O3 Alumina Ceramic Polishing Plate with Fine Electrical Insulation