Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

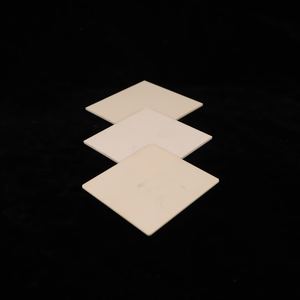

Overview of High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates

High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates)

Specification of High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates

Alumina ceramic sheets use excellent mechanical strength. They are plates made from aluminum oxide. This material is very hard. It resists scratches and wear very well. These plates will not break quickly under pressure. They take care of heavy tons effectively. High purity alumina does finest. Usual grades are 95% and 99% Al2O3. Greater purity indicates better toughness and firmness.

These ceramic sheets withstand extreme warmth. They operate accurately above 1500 ° C. Sudden temperature level adjustments will not break them. They have superb thermal shock resistance. This makes them ideal for heating systems and high-heat zones. Electric insulation is an additional crucial advantage. Alumina plates are fantastic insulators even at high voltages. They avoid electric present flow successfully.

Chemical security is a major advantage. Alumina withstands acids and alkalis well. It does not wear away conveniently. Harsh environments are not a trouble. Surface level of smoothness is achievable. Plates come in numerous surfaces. Accuracy grinding creates fine surfaces. Basic densities range from slim shims to thick plates. Common sizes are readily available. Customized measurements are commonly feasible.

These plates are used in demanding applications. They secure surface areas subject to hefty wear. They serve as solid electric insulators. They line high-temperature devices. Equipment components benefit from their toughness. Semiconductor tools use them frequently. Just include protective edges where needed. They are common in heavy machinery parts.

(High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates)

Applications of High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates

Alumina ceramic sheets offer phenomenal mechanical strength. This makes them ideal for tough jobs. Many sectors count on these Al2O3 plates. They deal with extreme wear and pressure very well. Factories utilize them heavily. They line chutes handling abrasive materials like sand or minerals. This lining lasts a lot longer than steel. The plates withstand constant scratching. Alumina ceramic sheets stand up to high temperatures as well. Heating system linings benefit from this. They provide excellent thermal insulation. Kilns and heaters utilize them as safety layers. The material does not conveniently split under warmth tension.

Electronics need reliable insulation. Alumina sheets are perfect electrical insulators. They keep components secure. Motherboard usually use them as substratums. The material securely holds conductive paths. It additionally handles warmth properly. Semiconductor devices utilizes these plates for vital parts. The strength avoids damages during assembly. Alumina ceramic sheets are chemically inert. Harsh chemicals do not damage them conveniently. Chemical plants install them in reaction vessels. Pump seals made from alumina last well. They stand up to deterioration from acids or bases. Waste therapy systems utilize them for longevity.

The medical field worths biocompatible materials. Alumina ceramic sheets are safe inside the body. They are utilized in strong joint replacements. Dental implants additionally use this tough ceramic. It holds up against eating pressures. The product is really tough. It resists scrapes and surface area wear. Cutting devices get covered with alumina layers. This finishing makes blades last much longer. Automotive parts make use of alumina for toughness. Automobile manufacturers put them in ignition system. They endure engine heat and vibration. Alumina ceramic sheets are flexible trouble solvers. Their solidity and strength solve several engineering difficulties.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates

Here are 5 FAQs about High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates:

What are high mechanical strength Alumina Ceramic Sheets?

These are plates made primarily from aluminum oxide (Al2O3). They are very hard. They resist wear extremely well. They are strong under pressure. They handle high temperatures. They resist chemical corrosion. This makes them useful for tough jobs.

What thicknesses are available?

These plates come in many thicknesses. Common sizes range from thin sheets around 1mm up to thick plates over 25mm. The exact sizes depend on the maker. You can choose the thickness needed for your specific job.

How much heat can they take?

Alumina ceramic plates handle very high heat. They work fine continuously at temperatures over 1500°C (2732°F). Their melting point is much higher, near 2050°C (3722°F). They also resist sudden temperature changes well.

Where are they used?

Their strength and toughness make them ideal for demanding spots. You see them as wear liners in mining equipment. They protect machinery parts from abrasion. They are used in high-heat furnace parts. They work as electrical insulators in demanding settings. They are also used in cutting tools and seals.

Can you cut or machine them?

Yes, you can machine them. But it requires special tools. Diamond grinding wheels are necessary. Standard metal cutting tools won’t work. Machining is slow. It needs careful handling. It’s best done by experienced shops with the right equipment to avoid cracking the ceramic.

(High Mechanical Strength Alumina Ceramic Sheet Al2O3 Plates)

REQUEST A QUOTE

RELATED PRODUCTS

Wear Resistant Alumina Ceramic Plate Al2o3 Ceramic Substrate

95% Alumina Ceramic Substrate Ceramic Plates for Industrial Use Custom Cutting Processing Service

Soft PE 3A Tactical Safety Vest Alumina Silicon Carbide Ceramic Plate Insertion 4IV Ceramic Plate Armored Panel Equipment

Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

Impact Resistant Alumina Ceramic Tile Polyurethane Wear Lining Plate