Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

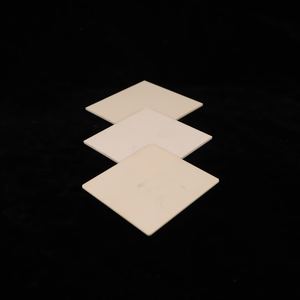

Overview of High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts

High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts)

Specification of High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts

This alumina ceramic material is Al2O3. It is extremely difficult. It resists wear very well. It manages high warm conveniently. These buildings make it perfect for tough jobs. We make many forms: plates, obstructs, rods, tubes, rings, blades, bearings. You need exact parts? We device them precisely.

Every surface gets mirror brightened. This sprucing up is careful. The result is an incredibly smooth coating. This level of smoothness is critical. It reduces rubbing. It avoids material sticking. It maintains surfaces clean much longer. Accuracy is ensured. We hold tight dimensional resistances. Monotony and parallelism are controlled purely. Round components remain completely rounded. This precision makes certain reliable efficiency.

These parts are strong. They resist chipping and breaking well. They withstand severe thermal shock. Sudden temperature changes are not a problem. They are chemically inert as well. Acids and bases don’t damage them. Corrosion is not an issue. Electric insulation is superb. These attributes are crucial for numerous uses.

You discover these parts popular places. Semiconductor making uses them greatly. Wafer handling requires smooth, tidy surfaces. Clinical devices relies on their biocompatibility. Industrial equipment utilizes them for wear resistance. Laser systems require stable, heat-resistant elements. High-performance bearings benefit from their solidity. Cutting tools utilize alumina blades for long life. Seals and insulators in extreme settings depend upon them.

The mirror gloss extends life span significantly. Surfaces stay cleaner. Put on is reduced dramatically. Maintenance needs decrease. Parts last much longer. This conserves money in time. Performance remains regular. Reliability improves. These parts are a smart investment for crucial applications. They address tough design troubles effectively.

(High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts)

Applications of High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts

High accuracy Al2O3 ceramic parts are important. They are made from very pure alumina. This product is incredibly tough. It withstands wear extremely well. These components take care of high temperatures easily. They are additionally excellent electrical insulators. Chemical corrosion hardly ever impacts them. These properties make them vital for requiring tasks.

You find these components in many shapes. Typical forms include plates, blocks, poles, tubes, rings, blades, and bearings. Each shape serves particular demands. Mirror sprucing up is an essential finishing action. It creates an ultra-smooth, reflective surface. This minimizes friction considerably. It also protects against contamination accumulation.

These ceramic parts are critical in semiconductors. They hold silicon wafers during handling. Their smoothness avoids scrapes. Their pureness stays clear of contaminating sensitive chips. Laser systems rely on them also. Precision ceramic rods and tubes overview laser light beams accurately. Their stability guarantees consistent efficiency.

Industrial setups use them heavily. Ceramic blades cut materials easily without wearing down swiftly. Ceramic bearings run efficiently in extreme problems. They require less lubrication than metal bearings. They last much longer under tension. High temperature heating systems utilize alumina plates and tubes as linings. They stand up to intense heat without deteriorating.

Clinical gadgets benefit significantly. Alumina ceramic components are biocompatible. The human body tolerates them well. They are utilized in joint substitutes and medical tools. Their smoothness decreases cells inflammation. Their stamina guarantees integrity. Analytical instruments use them for example handling. Their inertness warranties exact examination results.

These ceramics address problems metal or plastic can not. They carry out dependably where others stop working. Their unique combination of firmness, warmth resistance, and chemical stability is unparalleled. Industries need products that push restrictions. High precision Al2O3 ceramic components meet that need. They make it possible for sophisticated modern technology and efficient production.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts

High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts: Your Top Questions Answered

What makes Al2O3 ceramic good for precision parts?

Alumina ceramic is very hard. It resists wear extremely well. The material stays strong against chemicals. It handles high heat without changing shape. These traits make it perfect for tough jobs needing accuracy.

How hot can these parts get?

Our high purity Al2O3 parts work reliably up to 1650°C. They keep their strength and shape at these temperatures. This is much better than metal or plastic parts. Use them confidently in hot environments.

Where are these parts typically used?

You find them in many demanding places. Semiconductor equipment uses them a lot. Laser systems need them. Medical devices rely on their precision. Industrial machinery uses them for wear parts. Any place needing smooth, hard, stable surfaces considers them.

Can you make custom sizes and shapes?

Yes. We specialize in custom Al2O3 ceramic parts. Tell us your exact needs. We make square blocks, rods, tubes, rings, blades, bearings. We achieve the tight tolerances you require. Mirror polishing is standard for ultra-smooth finishes.

How smooth is the mirror polish?

The mirror polish is extremely smooth. It feels like glass. This finish minimizes friction. It reduces particle generation. It improves sealing performance. It also makes cleaning easier. Surface quality is critical for many applications.

(High Precision Al2O3 Ceramic Plate Mirror Polished Alumina Square Block/Rod/Tube/Ring/Blades/Bearings Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Alumina Engineering Ceramic Thin Substrate \/ Sheet \/ Plate \/ Board

Alumina 95 Porcelain Ceramic Suction Plate Porous Ceramic Plate 5 groove Thick Orifice Plate

High Hardness 95% Alumina Al2o3 Metallized Ceramic Plate in Electrical

4mm 99% Pure Alumina Ceramic Plates With Square Hexagon

Faucet Cartridge 15mm 35mm Alumina Ceramic Disc Ceramic Plate for Tap