Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

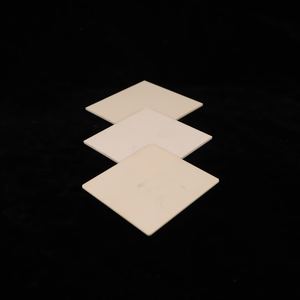

Overview of High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner

High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner)

Specification of High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner

These high quality customized alumina ceramic plates deliver solid efficiency. They are made from light weight aluminum oxide product. This material is very hard. It withstands wear extremely well. These plates manage high temperatures quickly. They also fight chemical corrosion effectively. They function dependably in challenging problems.

You can tailor these plates to your precise demands. They are available in lots of sizes and shapes. Usual densities range from 3mm to 50mm. Larger sizes are feasible as well. We provide two main pureness qualities: 92% and 95%. The 95% quality is harder and denser. It provides better wear resistance. The 92% grade uses great performance at a lower cost. Pick the most effective grade for your specific work.

Surface area finish issues. Alternatives consist of smooth polished surfaces. We also supply harsh surfaces for far better hold. The surface influences friction and wear. We can machine the plates specifically. We can pierce openings or cut special shapes. Tell us your requirements. We make the plates fit your devices flawlessly.

These ceramic plates are really functional. They are ideal for lining chutes and receptacles. They shield against rough products. They function well as ceramic rubber linings. The ceramic floor tiles bond firmly to rubber sheets. This develops a solid, adaptable composite liner. This liner soaks up effect. It also stands up to cutting and tearing. The ceramic surface takes the wear. The rubber backing absorbs shock. This mix lasts longer.

You additionally find these plates in mining devices. They line cyclones and pipeline bends. They shield equipment components revealed to hefty wear. They are made use of in power plants and steel mills. They manage rough coal and ash. They stand up to high heat in furnaces. They are located in material handling systems. They protect tools from consistent abrasion. These plates extend the life of your equipment. They minimize downtime and upkeep prices.

(High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner)

Applications of High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner

Premium quality personalized alumina ceramic plates deliver excellent security. These floor tiles come in 92% and 95% aluminum oxide pureness qualities. Both types use exceptional solidity and resistance to use. They deal with serious abrasion efficiently. Alumina ceramic plates are a leading choice for lining tools. They shield equipment from damage caused by rough products.

These plates work well as ceramic rubber liners. The mix is very effective. The tough ceramic surface takes the straight effect and abrasion. The flexible rubber support takes in shock and vibration. This dual-layer system lasts much longer than rubber alone. It considerably cuts downtime and replacement costs. The bond in between ceramic and rubber is really solid. It stops floor tile loss throughout procedure.

Personalization is crucial for these alumina plates. They are precisely cut and formed to fit particular devices. Typical forms consist of blocks, ceramic tiles, sheets, and mosaic plates. Mosaic plates feature tiny ceramic tiles bound to a rubber sheet. This layout provides flexibility for complicated curves. It streamlines installment on chutes, hoppers, and pipelines.

These ceramic liners are crucial in many difficult markets. Mining operations rely upon them greatly. They line chutes, transfer points, and truck beds. They shield against continuous rock and ore abrasion. Nuclear power plant utilize them in coal handling systems. They line bunkers, feeders, and pulverizer inlets. Concrete plants mount them in raw mills and finish mills. They hold up against the grinding activity of clinker and raw meal.

Product handling tools advantages substantially. Conveyor systems make use of ceramic rubber linings at loading zones. They secure belts and frameworks from impact. Screw conveyors and container elevators use these linings too. They prolong the life of moving components subjected to rough circulations. The alumina ceramic surface area remains smooth over time. This decreases rubbing and material accumulation. It keeps product streaming freely.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner

What are these ceramic plates made from?

They’re crafted from premium alumina. The material comes in two purity grades: 92% and 95% aluminum oxide. This high alumina content is key. It makes the plates incredibly tough and resistant to damage.

Why choose alumina ceramic plates?

These plates offer major advantages. They are extremely hard, nearly as hard as diamonds. They resist wear exceptionally well. They handle intense heat without degrading. They also withstand chemical corrosion. This combination means they last much longer than many other materials.

Can I get these plates made to my exact needs?

Yes, absolutely. That’s a core feature. We produce plates customized to your specific project. You tell us the size, thickness, and shape you need. We manufacture them precisely to those dimensions. This ensures a perfect fit for your application.

How are these ceramic plates installed?

Installation is straightforward. The plates are usually attached to a sturdy metal backing plate. They are then fixed onto the equipment surface needing protection. Common methods include using strong adhesive or specialized bolts. The best method depends on your specific setup and the forces involved.

Where are these custom plates typically used?

They are vital in heavy industries needing wear protection. You find them lining equipment in mining operations, like chutes and hoppers. They protect power plant machinery handling abrasive coal or ash. They are used in cement production facilities. They shield equipment in steel mills. Anywhere severe abrasion or impact occurs, these plates are a reliable shield.

(High Quality Customized 92% 95% Alumina Ceramic Plate Block Aluminium Oxide Tile Sheet Mosaic Plate for Ceramic Rubber Liner)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Hot Resistance C795 95% Alumina Ceramic Insert Plate

Alumina Ceramic Honeycomb Filter Plate for Industrial Usage

Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board

Whole Customize 99 Al2O3 Industrial Insulation High Heat Resistant Alumina Ceramic Disc Plate Alumina Ceramic Tube

High Hardness Aluminum Oxide Ceramics Sheet Panel Hexagon Type Al2o3 Alumina Ceramic Insert Plate