Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

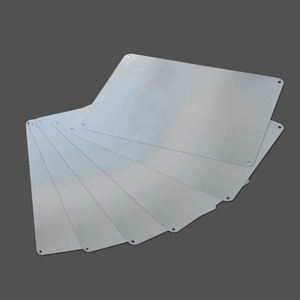

Overview of High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board

High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board)

Specification of High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board

This high performance ceramic plate insert is custom-made made for your strike face board needs. We build it challenging in our manufacturing facility making use of top grade alumina ceramic material. This sophisticated ceramic is exceptionally hard. It effectively stops bullets and pieces. The firmness rating is very high. It withstands scrapes and put on remarkably well. This material option issues. It ensures long lasting defense for critical applications.

Our inserts are not off the rack things. We personalize them specifically for your board. Give us your particular dimensions and form needs. We produce the exact ceramic plate you need. This customized installation is crucial. It assures the insert incorporates flawlessly into your overall shield system. An ideal fit makes the most of protection. It likewise prevents powerlessness.

We concentrate on durability. Our alumina ceramic plates are created to soak up significant impact power. They are shatter-resistant. This toughness is essential under high anxiety problems. The ceramic breaks apart strategically. This action reduces and stops threats efficiently. Dependability is non-negotiable in protection gear. Our plates supply constant efficiency.

These inserts suit lots of requiring usages. They secure armed forces automobiles efficiently. They are crucial for tactical body shield vests. Safety and security personnel and police rely on them. Any kind of situation requiring solid, lightweight strike face protection benefits. Our manufacturing facility utilizes stringent quality control. Every ceramic plate set undergoes rigorous screening. We inspect solidity, density, and effect resistance thoroughly. You obtain confirmed top quality every time. We assure the product purity and manufacturing accuracy. Count on our competence for your vital armor component.

(High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board)

Applications of High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board

Military armor makes use of these inserts heavily. Soldiers need light-weight defense. Tough alumina ceramic plates quit bullets effectively. They consider much less than steel plates. Soldiers move much better and tire less. Automobile shield additionally advantages. Humvees and APCs use ceramic strike face boards. They secure versus shrapnel and tiny arms fire. The ceramic takes in effect power well. Vehicle crews stay safer inside.

Industrial setups need hard protection also. Mining tools faces constant abrasion. Crushers and chutes get harmed swiftly. Customized ceramic inserts line these devices. They withstand use much longer than steel. Manufacturing downtime drops considerably. Upkeep prices fall. Security setups utilize ceramic boards in crucial locations. Checkpoint obstacles and guard booths need reputable securing. Alumina ceramic quits high-velocity hazards. Safety and security workers have far better cover.

The factory modification matters significantly. Every application has special demands. Plate size, density, and placing points vary. Manufacturing facilities make specific subassemblies prepared for installation. This saves time at work site. Employees fit the pre-made units swiftly. Alumina ceramic itself is really hard. It is more difficult than the majority of metals. This firmness quits projectiles chilly. It also stands up to extreme warmth and chemicals. The material stays secure under anxiety. It does not flex or warp like steel. This integrity is vital for life-saving equipment.

Weight financial savings are a major advantage. Traditional steel shield is hefty. It limits flexibility and pressures automobiles. Alumina ceramic deals comparable protection at half the weight. Operators gain rate and endurance. Automobiles save gas and manage far better. The ceramic strike face shatters on impact. This action absorbs the projectile’s power. The backing product catches fragments. This split technique works finest.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board

What is the Hard Alumina Ceramic Plate Insert Subassembly?

This is a custom-made part for strike face boards. It uses high-quality alumina ceramic. The material is extremely hard. It protects against impacts and abrasion. Factories shape it to fit specific designs.

Why pick alumina ceramic for this insert?

Alumina ceramic offers top hardness. It resists scratches and wear. It handles high temperatures well. It does not rust or corrode. This makes it last longer than metals or plastics.

Can I get custom sizes and shapes?

Yes. Factories customize every detail. You choose the thickness, length, and hole patterns. They match your strike face board exactly. This ensures a perfect fit.

How tough is the ceramic against impacts?

Very tough. Alumina ceramic absorbs heavy shocks. It stops cracks from spreading. It stays strong after repeated hits. This keeps the strike face safe.

How do I attach the insert to the board?

Use bolts or industrial adhesive. The insert has pre-drilled holes. Align it with the board. Secure it tightly. Follow the factory’s guide for best results.

(High Quality Factory Customized Hard Alumina Ceramic Plate Insert Subassembly for Strike Face Board)

REQUEST A QUOTE

RELATED PRODUCTS

Customized 99% Alumina Ceramic Plate for Sintering Al2o3 Slab Aluminum Oxide Ceramic Sheet

Square Al2o3 Aluminum Oxide Alumina Ceramic Plates for Furnace

92% 95% Whole Ceramic Plates Alumina Ceramic Alumina hexagonal plain tile

Precise Alumina Al2o3 Porous Ceramic Plate s for Micro Bubble Diffuser

Factory Supply Customized Insulated High Alumina Corundum Plate Sintered Alumina Oxide Plate Ceramic Alumina Plate