Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

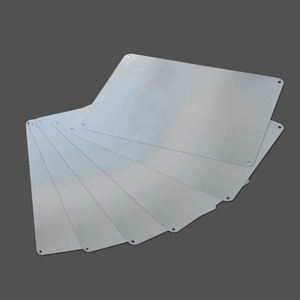

Overview of High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services

High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services)

Specification of High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services

High stamina alumina ceramic foam filters deliver reliable performance in demanding industrial setups. These industrial ceramic plates manage intense warm throughout welding, cutting, and bending procedures. They stand up to thermal shock efficiently. Alumina ceramic deals exceptional solidity. This material withstands abrasion and put on in time. The open-cell foam framework is vital. It catches pollutants and slag from liquified steel efficiently. Cleanser metal flow results directly. This boosts end product quality dramatically. Employees value home plates’ resilience. They last much longer than numerous choices. Downtime for replacements lowers. Price cost savings end up being recognizable.

These ceramic plates preserve dimensional stability under severe conditions. They don’t warp or distort easily. Constant performance is assured. Precision cutting operations profit significantly. The plates supply a secure, heat-resistant surface. Bending accuracy enhances. Weld high quality typically sees improvement. Alumina ceramic resists chemical assault well. Harsh industrial environments pose little hazard. Deterioration is seldom a problem. Long-term dependability is assured.

The porous filter style permits gases to get away freely. Entraped gases cause defects in finished products. Minimizing porosity problems is a major benefit. Metalworkers locate these plates easy to take care of. Their high strength-to-weight proportion is a practical benefit. Setup times are frequently quicker. Processing speeds can increase securely. These filters appropriate for ferrous and non-ferrous steels. Convenience throughout various applications is a strong point. Manufacturing plants see enhanced effectiveness. Waste material lowers. Manufacturing prices usually go down. High pureness alumina makes sure constant filter performance set after batch.

(High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services)

Applications of High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services

High strength alumina ceramic foam filters tackle laborious in metal casting. They get rid of pollutants from liquified metal. This takes place during putting. Light weight aluminum factories depend on them. So do brass and bronze producers. The open-cell foam structure traps undesirable bits properly. This leads to cleaner steel. Cleanser metal suggests less issues in final castings. Surface quality boosts considerably. Mechanical homes get better as well. Return prices increase for shops. Utilizing these filters conserves cash over time. They stand up to the severe heat of liquified metal baths. Their thermal shock resistance stops breaking. Operators locate them very easy to position in filter boxes. They fit basic systems. Constant performance set after set issues.

Industrial ceramic plates made from state-of-the-art alumina shield surface areas during warm work. Welding shops require them. Metal fabrication relies on them. Reducing tables use them thoroughly. These plates rest under the work area. They shield tables and tools from intense heat. Stimulates and spatter create no damage. The ceramic surface area remains awesome below. Employees avoid burnt equipment. Precision cutting and bending call for secure support. These plates give that level, tough surface. They resist abrasion from grinding and reducing debris. Maintenance ends up being easier. Downtime lowers. The plates manage hefty loads without cracking. Their long life offsets the first price. Steel fabricators appreciate the dependable security. They maintain production flowing efficiently. Quality keeps high on every job.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services

People often ask about our high strength alumina ceramic foam filters. Here are common questions and clear answers.

What exactly are these ceramic foam filters? They are porous plates made from pure alumina oxide. You place them in metal casting systems. Their job is trapping impurities in molten metal before it forms final products. They act like a very fine sieve.

Why pick alumina ceramic over other filter types? Alumina ceramic offers extreme heat resistance. This beats many plastic or metal filters easily. It also resists chemical attack from hot metal alloys. This combination means reliable, clean filtration every time.

How hot can these filters safely get? They handle temperatures exceeding 1600°C (2912°F) easily. This makes them perfect for demanding foundry work involving steel, iron, or high-temperature alloys. The heat won’t damage them during normal use.

Are these filters strong enough for tough jobs? Yes. The alumina material is inherently very hard and rigid. The foam structure provides good strength despite the many pores. They resist cracking under thermal shock and mechanical stress common in metal flow. They last a long time.

Can you get custom sizes or shapes? Absolutely. We manufacture filters in many standard sizes and thicknesses. Special dimensions or pore structures are also possible. Tell us your specific filtration needs. We can likely make a filter that fits.

(High Strength Alumina Ceramic Foam Filter Industrial Ceramic Plates for Welding Cutting and Bending Processing Services)

REQUEST A QUOTE

RELATED PRODUCTS

Al2O3 Ceramic Large Size Aluminium Oxide Ceramic Plates and Discs Alumina Ceramic Round Plate

Customized 99% Alumina Ceramic Plate for Sintering Al2o3 Slab Aluminum Oxide Ceramic Sheet

95% Alumina Ceramic Substrate Ceramic Plates for Industrial Use Custom Cutting Processing Service

Aluminium Oxide Al2O3 Alumina Ceramic Polishing Plate with Fine Electrical Insulation

High Temperature Wear Resistant Al2O3 96% Alumina Ceramic Solid Plate Brick Block