Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

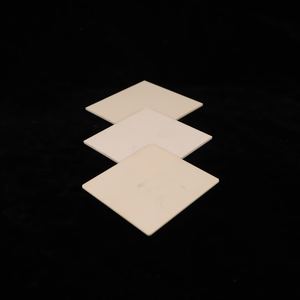

Overview of High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching

High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching)

Specification of High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching

These silicon carbide ceramic plates deal with extreme heat up to 1650 ° C. They are tough. They are dense. Their low porosity is key. This stops splitting under abrupt temperature level adjustments. You get reputable thermal shock resistance.

We make these plates with high-purity silicon carbide. We include alumina, magnesia (MgO), or silica (SiO2). This mix improves efficiency. It makes the plates stronger. It aids them last much longer under anxiety. They resist use well. They withstand chemical assault well.

These plates come as molded floor tiles or kiln racks. Their shapes are specific. Their surface areas are level. This is important for secure stacking in kilns. Heater applications require this too. The plates supply outstanding heat transfer. They distribute temperature evenly. Your firing results stay constant.

The product endures heavy tons. Its high mechanical strength is verified. Its high hardness is shown. Utilize these plates as long lasting surface areas for welding. Utilize them for punching procedures. They take care of straight contact with warm products. They take care of molten steel dashes. They resist abrasion from devices.

Physical properties are essential. Expect high thickness. Anticipate reduced porosity. Anticipate outstanding creep resistance at peak temperatures. These plates won’t warp conveniently. They won’t droop quickly under lengthy warm direct exposure. This makes certain dimensional stability. Your processes remain precise.

These plates change typical materials. Conventional products usually fail at lower temperatures. They weaken much faster. Our silicon carbide plates offer much longer service life. They reduce downtime. They reduced substitute prices. Industries like porcelains rely upon them. Steel processing relies upon them. Heat treatment counts on them. Any type of high-heat setting needs dependable support.

(High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching)

Applications of High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching

These silicon carbide ceramic plates manage extreme heat up to 1650 ° C. That makes them excellent for tough jobs needing serious temperature level resistance. They are much stronger than regular ceramics. They stand up to thermal shock extremely well. This suggests they do not fracture conveniently when temperature levels change fast. They likewise last a long time under heavy loads. Their reduced thermal expansion maintains their size stable. This is vital for precision job.

One major use is as kiln racks. These plates hold items throughout shooting in ceramics, metals, or glass kilns. They support hefty weights at max temperature level without bending. They do not contaminate the terminated items. This keeps the final products pure. They also warm up and cool effectively, saving power.

In powder metallurgy, they serve as steady powder plates. These plates hold metal powders throughout sintering processes. The plates require to remain flat and smooth under heat. This makes certain the sintered components come out appropriately formed. Their chemical inertness quits reactions with the powders.

These plates work well as welding fixtures as well. They hold parts securely during high-temperature welding. The plates hold up against the warm without deteriorating. This offers consistent results. They likewise secure delicate areas from warm damages.

For punching operations at heats, these porcelains are outstanding strike faces or dies. They stay hard and stand up to wear also when hot. This maintains punching precise over several cycles. They handle the impact forces dependably.

The Alumina/MgO/SiO2 ingredients aid tweak the homes. This tailoring makes sure leading performance for each and every particular laborious, whether kiln rack, powder plate, welding tool, or punching die.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching

What temperature can these silicon carbide plates handle? They withstand temperatures up to 1650°C. This makes them perfect for very hot kilns. They won’t warp or break down easily under extreme heat.

What are these plates made from? They use silicon carbide ceramic. Alumina, magnesia, and silica are also key parts. These materials give the plates their strength and heat resistance. They help the plate survive repeated heating and cooling.

Where do people use these ceramic plates? They are mainly kiln shelves. They hold items being fired inside furnaces. People also use them as powder plates for welding. Sometimes they act as moulded tiles or punching tools in high-heat processes. They are very versatile.

How long do these plates last? They are very tough. They resist thermal shock well. They handle rapid temperature changes without cracking. They are also wear-resistant. This means they last much longer than cheaper shelves. They save money over time because replacements are less frequent.

How should I handle these plates? Be careful. Silicon carbide is strong but can be brittle. Avoid dropping them or hitting them hard. Protect the edges. Don’t expose them to sudden, extreme temperature shifts. Always follow the kiln’s heating and cooling schedule. This prevents thermal stress cracks.

(High-Temperature 1650C Silicon Carbide Ceramic Plates Alumina/MgO/SiO2 Moulded Tiles Kiln Shelf Powder Plate Welding Punching)

REQUEST A QUOTE

RELATED PRODUCTS

92% 95% Alumina Ceramic Lining Tile Plate Wear-Resistant Welding Protection Cut-to-Size Refractory Application

Impact Resistant Alumina Ceramic Tile Polyurethane Wear Lining Plate

96% Al2o3 Alumina Substrate Ceramic Parts Ceramic Square Plates

Al2O3 Ceramic Large Size Aluminium Oxide Ceramic Plates and Discs Alumina Ceramic Round Plate

Structural Parts 95 99 Alumina Ceramic Substrate / Sheet / Plate / Board