Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

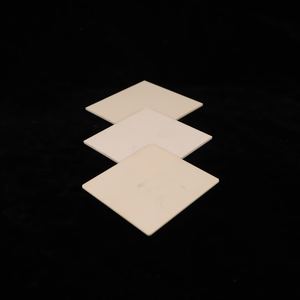

Overview of Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services)

Specification of Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

Industrial ceramic alumina plates supply extraordinary efficiency for requiring industrial jobs. These square ceramic components are crafted from high-purity alumina. This product supplies superior firmness. It resists wear extremely well. Our alumina plates deal with extreme heat conveniently. Temperatures surpassing 1600 ° C are no problem. This makes them excellent for high-temperature applications.

You require trustworthy parts for cutting, molding, or welding. These alumina plates are the remedy. Their thermal security avoids warping under extreme warm. They preserve dimensional accuracy throughout handling. Constant results issue. These plates deliver that uniformity. They last long under challenging conditions. This minimizes downtime and replacement costs.

We supply alumina plates in numerous dimensions and thicknesses. Square shapes are basic. Custom-made dimensions are likewise readily available. Tell us your details needs. We can satisfy them. Our plates offer perfectly as wear-resistant liners, warmth barriers, or precision fixtures. Their electrical insulation properties are excellent as well.

Beyond supplying standard plates, we provide customized handling services. Required specific cutting? We deal with that. Complicated shapes call for molding? Our proficiency supplies. Specialized welding applications need assistance? Our ceramic components stand up to the environment. We equipment alumina to your specific requirements. High quality is our priority. Every piece satisfies stringent criteria. We make sure integrity for your vital processes.

(Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services)

Applications of Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

Industrial ceramic alumina plates are important in challenging commercial setups. These square ceramic parts handle extreme problems easily. Alumina ceramic is extremely tough. It resists wear extremely well. This material withstands temperature levels approximately 1600 ° C. It does not melt or compromise like steels usually do. This makes alumina ideal for high warm applications.

Heating system linings and kiln furnishings utilize these plates. They hold best-sellers securely. Semiconductor handling equipment relies on them also. They give secure, non-contaminating surface areas. Welding components need warmth resistance. Alumina plates offer it dependably. They insulate electrically in high-power welding configurations. This prevents unsafe shorts.

Cutting devices gain from alumina’s firmness. Alumina parts shape other products exactly. They last much longer than steel in rough tasks. Molding passes away face consistent stress and warmth. Alumina plates handle this stress well. They maintain form for consistent manufacturing runs. This minimizes downtime and substitute prices.

Processing solutions are crucial for custom-made requirements. Vendors supply precise cutting of alumina plates. They can pierce holes and develop intricate shapes. Edge grinding makes certain smooth, safe coatings. Surface area polishing is readily available for particular applications. These services create components ready for prompt use. They conserve makers effort and time.

Alumina plates deal excellent electrical insulation. They work in high-voltage environments safely. Their chemical inertness matters also. Rough acids or alkalis do not harm them. This ensures lasting reliability. They are a wise selection for requiring commercial processes.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services

Industrial ceramic alumina plates are precision ceramic parts. They handle extreme heat. Many customers ask questions. Here are five common ones.

What exactly are these ceramic plates? They are square parts made from high-purity aluminum oxide. This material is very hard. It is also very stable under intense heat. We make them using advanced processes. This ensures consistent quality and tight tolerances. They are ready for tough jobs.

Why pick alumina ceramic for high temperatures? Alumina ceramic keeps its strength even above 1600°C. It doesn’t melt easily. It resists wearing down. It doesn’t react with many chemicals. This makes it perfect for hot environments. Metal parts often fail here. Alumina lasts much longer.

Where are these plates used most? They are vital in high-heat processes. Examples include welding fixtures. They position hot metal parts. Cutting tools use them as wear surfaces. Moulding processes need them for handling hot materials. Furnace linings benefit from their heat resistance. Any place needing reliable heat protection uses them.

Can I get custom sizes and shapes? Yes. We specialize in custom ceramic machining. We cut, grind, and drill these plates. We use CNC machines for precision. Tell us your exact dimensions. We make the part fit your specific application. Need holes or special edges? We do that too.

Why choose ceramic over metal for these jobs? Ceramic resists heat better than most metals. It doesn’t warp or soften. It is harder than steel. This means less wear over time. It insulates heat well. This protects surrounding equipment. It saves money long-term. Replacement happens less often. Performance stays high.

(Industrial Ceramic Alumina Plate Square Ceramic Parts High Temperature Applications Cutting Moulding Welding Processing Services)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Resistant Alumina Al2o3 Ceramic Solid Block Brick Plate

Customizable 130*30*40mm High Temperature 85% Alumina Ceramic Plate Industrial Use with 12mm Hole

Faucet Cartridge 15mm 35mm Alumina Ceramic Disc Ceramic Plate for Tap

99Al2O3 Industrial Alumina Ceramic Plate

Al2O3 Alumina Ceramic Plates Sheet 95-99% Aluminum Oxide for Structure Ceramic Burner