Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

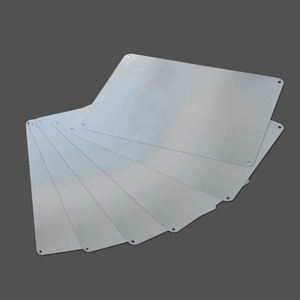

Overview of Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate

Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate)

Specification of Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate

Market wear-resistant alumina ceramic sheets supply unmatched resilience for difficult applications. These Al2O3 ceramic plates are made from high-purity light weight aluminum oxide. They supply severe surface firmness. This firmness directly combats unpleasant wear. The plates stand up to scratching and gouging extremely well. This makes them best for shielding tools surfaces.

Alumina ceramic plates are extremely thick. This thickness adds to their strength. They take care of high impact forces without cracking. These ceramics preserve efficiency under heavy loads. They are much lighter than equal steel components. This minimizes weight stress and anxiety on equipment. Lower weight helps with installation as well.

The product holds up against high temperatures. It keeps its properties in hot settings. Alumina is chemically inert. It withstands attack from acids and alkalis well. This prevents corrosion damage with time. The plates stay stable in rough chemical setups. This is vital for many commercial processes.

These ceramic sheets are non-sparking. They are secure for explosive settings. They also resist electrical currents. This includes security in electrical applications. Their smooth surface lessens friction. This minimizes energy loss and warmth buildup. Much less friction suggests less wear on moving parts.

Typical uses include lining chutes and hoppers. They secure conveyor systems from rough materials. They secure pipes lugging slurry. They are utilized in mining devices thoroughly. Nuclear power plant utilize them for coal handling. They are found in concrete manufacturing equipment. Anywhere abrasion damages steel, alumina ceramic plates excel.

Installation is simple. The plates affix with screws or adhesive. They bond firmly to steel surfaces. Proper surface area prep is essential for adhesion. Normal cleaning keeps them carrying out well. They require marginal upkeep long-term. Their lifespan much surpasses conventional steel linings. Substitute expenses go down substantially. Downtime for repair services lowers.

(Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate)

Applications of Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate

Industry wear-resistant alumina ceramic sheets solve difficult problems. These Al2O3 ceramic plates handle severe deterioration. They are made from high-purity light weight aluminum oxide. This product is really tough. It is much more challenging than steel. This hardness combat abrasion. Abrasion puts on down components rapidly. These plates quit that.

Mining procedures depend on these porcelains. Ore and rock are very rough. Conveyor linings, chutes, and receptacles get consistent abuse. Alumina layers secure these surface areas. They last much longer than steel liners. This cuts downtime and substitute costs. Concrete plants encounter similar issues. Basic material and clinker grind away devices. Ceramic plates line cyclones, separators, and ducting. They withstand the continuous sandblasting result.

Steel mills need warmth resistance also. Alumina ceramic plates provide that. They handle heats well. They line equipment handling warm products. Assume sinter plants and furnace feed systems. Home plates stand up to both warmth and abrasion. Nuclear power plant use them in coal handling. Coal pulverizers and ash systems wear quick. Ceramic liners expand equipment life substantially. They take care of the erosive fly ash.

Chemical plants take care of corrosion. Alumina ceramic is chemically inert. It withstands many acids and antacids. This makes it perfect for lining mixers, storage tanks, and pipes bring rough chemicals. It fights wear and corrosion with each other. Home plates are also really dense. This density stops liquids from soaking in. It maintains surfaces smooth and very easy to clean.

These ceramic plates been available in different dimensions and densities. They can be glued or bolted onto tools. Setup is typically uncomplicated. The primary advantage is durability. Devices runs longer between closures. Upkeep expenses drop. Production stays high. This saves money gradually.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate

Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate FAQs

What material is this ceramic plate?

This plate uses alumina ceramic. Its main component is aluminum oxide (Al2O3). This material gives it high hardness and excellent wear resistance. It’s ideal for protecting surfaces against abrasion.

Why does it resist wear so well?

Alumina ceramic is extremely hard. Its hardness is second only to diamond. Hard materials resist scratching and surface erosion much better than softer ones. This plate lasts longer in abrasive environments. It reduces equipment downtime and replacement costs.

How hot can it get?

This alumina ceramic plate handles high temperatures well. It works reliably up to about 1600°C (2912°F). Sudden temperature changes won’t easily crack it either. This makes it suitable for hot processes like material handling or kilns.

How do you install it?

Installing these plates is straightforward. Common methods involve bonding them with strong adhesive. You can also mechanically fix them using bolts or specialized fixtures. The best method depends on your specific equipment and the forces involved. Proper installation ensures they stay securely in place during operation.

Can you make custom sizes or shapes?

Yes, we offer extensive customization. We manufacture plates in many different thicknesses, widths, and lengths. We can also produce specific shapes like curves, cones, or complex geometries. Tell us your exact requirements. We will create ceramic plates to fit your machinery perfectly.

(Industry Wear-resistant Alumina Ceramic Sheet Al2O3 Ceramic Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Temperature Wear Resistance Alumina Ceramic Substrate Customized Ceramic Orifice Plate Parts with Cutting Bending Services

95% Alumina Ceramic Plate High Temperature Resistance Alumina Plate Ceramic Substrate

1mm 99% Al2o3 Alumina Ceramic Plate

95 Alumina Ceramic Plates Porous Ceramic Plates OEM Supply

PCB Used 96% 99.6% Technical Al2O3 Alumina Ceramic Thin Plate Substrate for Casting Industrial