Professional Premium Aluminum Oxide Products Supplier

PRODUCT PARAMETERS

Description

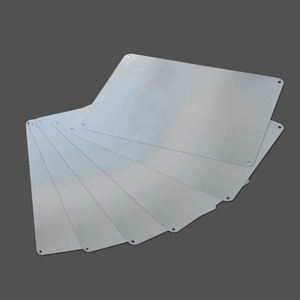

Overview of Insulation Material square Plate 95 Alumina Ceramic Sheet

Insulation Material square Plate 95 Alumina Ceramic Sheet is advanced ceramic components made from high-purity aluminum oxide (Al₂O₃), known for their exceptional hardness, thermal stability, and corrosion resistance. These plates are widely used in demanding industries such as electronics, aerospace, semiconductor manufacturing, and high-temperature furnace applications due to their superior electrical insulation and wear-resistant properties.

Key Features of Insulation Material square Plate 95 Alumina Ceramic Sheet

High Thermal Resistance :Withstands extreme temperatures up to 1600°C.

Excellent Electrical Insulation:Ideal for electronic substrates & insulators.

Superior Mechanical Strength:High hardness & wear resistance for long-lasting performance.

Chemical & Corrosion Resistance:Resists acids, alkalis, and harsh environments.

Customizable:Available in various sizes, thicknesses, and purity levels (96%-99.9%).

(Insulation Material square Plate 95 Alumina Ceramic Sheet)

Specification of Insulation Material square Plate 95 Alumina Ceramic Sheet

This ceramic sheet supplies exceptional electric insulation. It’s made from 95% alumina ceramic. This material is very difficult and strong. Alumina ceramic stands up to very heats well. It takes care of temperatures approximately 1650 ° C conveniently. This makes it ideal for demanding warm atmospheres.

The product offers exceptional electrical insulation buildings. It has extremely high dielectric strength. This avoids electric current from leaking. It dependably blocks high voltages. This is crucial for electric safety and security. The sheet has low thermal development. It doesn’t change dimension much with heat. This protects against splitting throughout rapid temperature level changes. It remains steady under thermal stress.

This alumina plate is chemically inert. It doesn’t react with many acids or antacid. It withstands chemical deterioration properly. This ensures long life in extreme problems. The product is very use resistant. It endures abrasion and disintegration. This makes it resilient for mechanical applications. It preserves its surface honesty in time.

The surface coating is smooth. It can be machined to accurate measurements. Typical thicknesses are 1mm, 2mm, 3mm, 5mm, 6mm, and 10mm. Standard sizes include 100x100mm, 150x150mm, and 200x200mm. Custom sizes are available. Individuals use these plates for many purposes. They work as heating system insulators, heating system linings, and circuit bases. They serve as electrical isolators in high-voltage equipment. They are substratums for sensing units and electronic parts. They serve as wear plates and thermal obstacles. Remember, alumina ceramic is fragile. Stay clear of solid influences during handling and installation.

(Insulation Material square Plate 95 Alumina Ceramic Sheet)

Applications of Insulation Material square Plate 95 Alumina Ceramic Sheet

This alumina ceramic plate takes care of extreme warmth. It does not let electrical power pass quickly. That makes it ideal for laborious. The plate is 95% pure alumina. This offers it fantastic strength and resistance. It keeps its shape also when things obtain very hot. It also resists chemical damage well. You locate this plate in several requiring areas.

Semiconductor production utilizes it a whole lot. It holds silicon wafers throughout high-temperature actions. Home plate doesn’t pollute the wafers. It deals with the intense heating system warmth reliably. Assembly line depend upon this security. It stops pricey mistakes and downtime.

Industrial heaters need reputable parts inside. This alumina plate is perfect. It lines locations revealed to high warm. It shields furnace walls and supports heating elements. The plate does not damage down like various other materials. It lasts much longer under extreme problems. This saves money on substitutes and maintenance.

High-power laser systems generate extreme warmth. This plate acts as a warm obstacle. It shields sensitive laser parts. The plate guarantees steady laser operation. It protects against overheating damages. Laser performance remains consistent due to it.

Home plate is additionally key in electric insulation. It separates high-voltage parts. This protects against unsafe electric shorts. Power systems and screening equipment utilize it for security. Its reliability is critical in these applications.

Numerous markets use it for wear defense. It lines devices where abrasion is an issue. Conveyor systems and processing machinery benefit. Home plate minimizes wear and expands tools life. It keeps equipment running efficiently much longer.

Company Profile

Alumina Technology Co., Ltd,. We focus on the research and development, production and sales of alumina products, serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Alumina Boat, Alumina Crucible, Alumina Dish, Alumina Foam Filter, Alumina Plate, Alumina Rod, Alumina Bar, Alumina Balls, Filter Alumina, Nano Alumina Powder, Spherical Alumina Powder, ect. please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Insulation Material square Plate 95 Alumina Ceramic Sheet

People often ask about our 95% Alumina Ceramic Square Plates. Here are common questions and answers.

What exactly is this material?

This is a high-grade ceramic plate. It’s made mostly from aluminum oxide, specifically 95%. This gives it special properties. It’s very hard and handles heat well.

Why is it good for electrical insulation?

This ceramic doesn’t conduct electricity. It’s an excellent insulator. It stops electrical current from flowing where you don’t want it. This makes it safe for electrical parts. It works even in demanding conditions.

How hot can it get without failing?

These plates withstand very high temperatures. They operate reliably up to about 1650°C (3000°F). They don’t melt or degrade easily at these heats. This suits them for furnaces and hot environments.

What sizes do you offer?

We supply square plates in standard sizes. Common options are 50x50mm, 100x100mm, 150x150mm. Thicknesses vary too, like 1mm, 2mm, 5mm, 10mm. Custom sizes are possible. Ask us about your specific needs.

Where is this plate typically used?

Its key uses are electrical and thermal insulation. You find it in furnace linings, heater bases, and electronic substrates. It’s used in high-voltage equipment. It protects sensitive parts from heat and electricity. Industries like aerospace, power generation, and semiconductor manufacturing rely on it.

(Insulation Material square Plate 95 Alumina Ceramic Sheet)

REQUEST A QUOTE

RELATED PRODUCTS

Customized High Anti-Impact Alumina Ballistic Ceramic Armor Plate Boron Carbide Square Patterns Industrial Use Welding Cutting

Aluminium Oxide Al2O3 Alumina Ceramic Polishing Plate with Fine Electrical Insulation

High Hardness Al2O3 99% Alumina Ceramic Body Protective Plate Ballistic Ceramic Armor Sheet

Polished Al2O3 Alumina Ceramic Plate

Hard Custom Rectangular Wear Resistant Alumina Insulation Ceramic Plate 95 96 99% Al2o3 Ceramic Board for Kiln